Double-sided conducting metal foil film belt and cable employing same

A technology of metal foil and film tape, applied in the direction of twisted/quad-stranded cables, bendable cables, cables, etc., can solve the problem of data transmission quality degradation, difficulty in obtaining bandwidth and transmission rate, and inability to To achieve the physical continuity and completeness of the shielding layer path, etc., to reduce the consumption of metal resources, enhance the EMI effect, and simplify the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

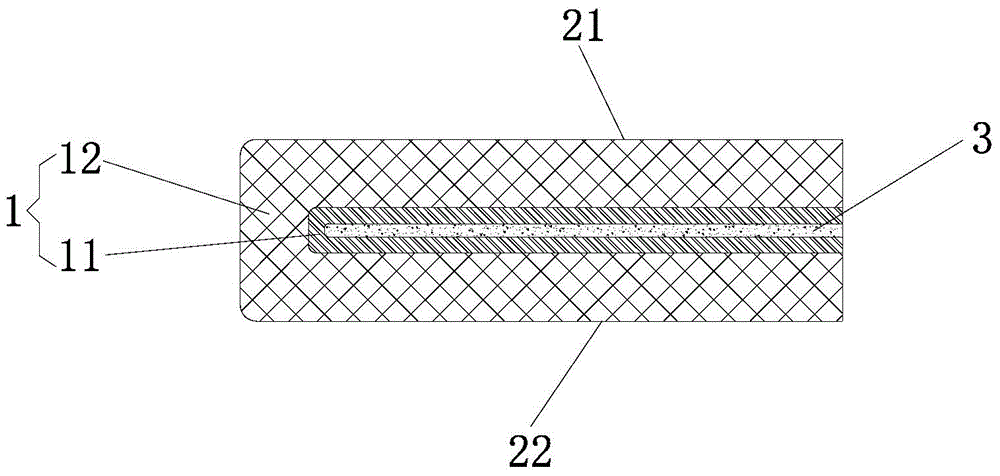

[0038] Such as figure 1 A double-sided conduction metal foil tape shown includes a base material 1, and the base material 1 is provided with a film layer 11 and a metal foil film layer 12 in sequence, and the film layer 11 adopts a film with longitudinal dimension stability, such as polyethylene terephthalic acid Ethylene glycol ester PET, polyethylene naphthalate PEN, polypropylene PP, polyimide PI, polyether ether ketone PEEK or polytetrafluoroethylene PTFE, in this embodiment, the film layer 11 adopts poly Ethylene glycol phthalate PET, the metal foil layer in the metal foil film layer 12 is an aluminum foil layer; the metal film layer in the metal foil film layer 12 is obtained by vacuum evaporation. The base material 1 is folded toward the film layer 11 to form an upper metal foil layer 21 and a lower metal foil layer 22. In this embodiment, the method of folding in half is adopted, that is, the widths of the upper metal foil layer 21 and the lower metal foil layer 22 are...

Embodiment 2

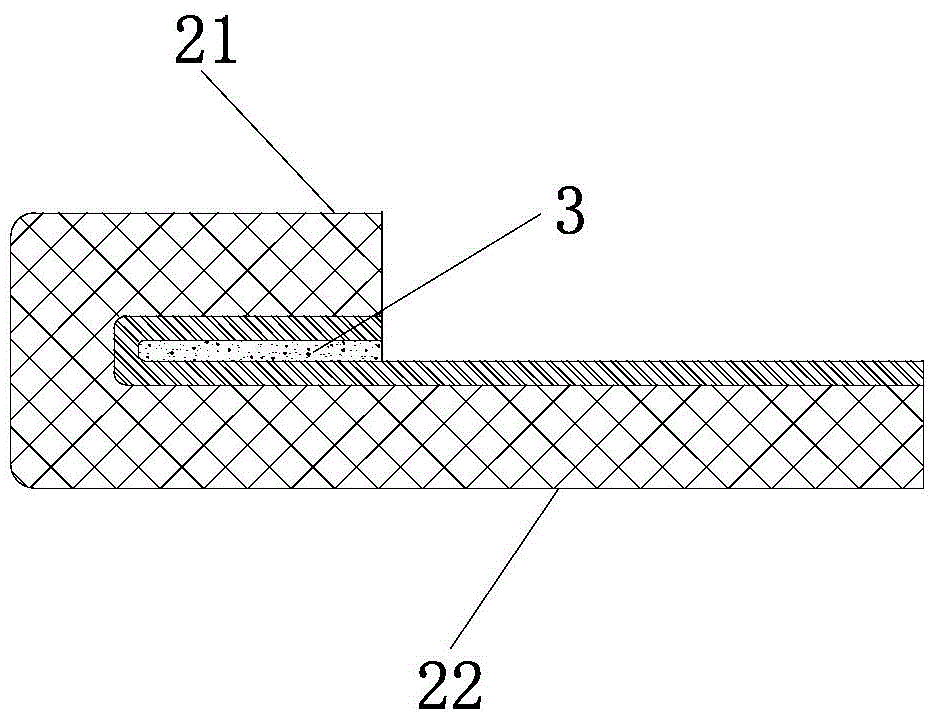

[0041] In this example, if figure 2 As shown, the width of the upper metal foil layer 21 is 30% of the width of the lower metal foil layer 22, of course, the width of the upper metal foil layer 21 can be selected according to needs, generally speaking, the width of the upper metal foil layer 21 is 10% to 100% of the width of the foil layer 22 . The film layer 11 is made of polytetrafluoroethylene PTFE, the metal foil layer in the metal foil film layer 12 is a copper foil layer, and the metal film layer is obtained by magnetron sputtering or ion plating. Other conditions are the same as in Example 1. Additionally, if Figure 4As shown, when in use, for the convenience of winding to the core wire, the metal foil tapes can be tightly bonded, and the film surface of the film layer 11 that exceeds the upper metal foil film layer 21 after the lower metal foil film layer 22 is bent is provided with heat. For the melt adhesive layer 3 , during use, the sticking temperature of the ...

Embodiment 3

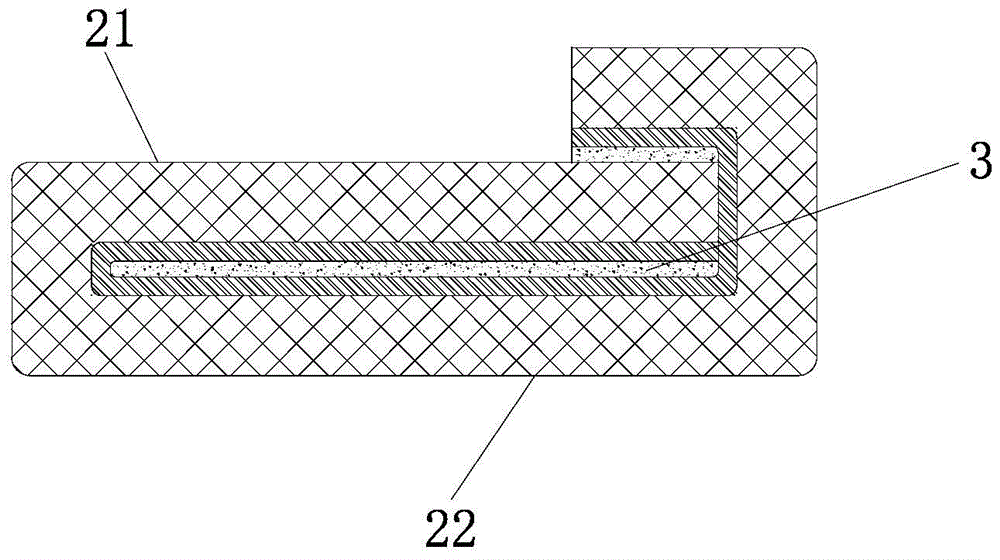

[0045] In this example, if image 3 As shown, the part of the lower metal foil layer 22 that exceeds the upper metal foil layer 21 is folded in the direction of the upper metal foil layer 21 and attached to the upper metal foil layer 21, that is, the excess is folded in half. The film layer 11 is a PP layer, the metal foil layer in the metal foil film layer 12 is a silver foil layer, and the metal film layer is obtained by ion plating, and other conditions are the same as in the first embodiment. In addition, the metal foil layer and the metal film layer can be used alone or laminated and composited. The metal foil layer can be one or more combinations of aluminum foil layer, silver foil layer or copper foil layer; One or more of sputtering, ion implantation plating and auxiliary plating, chemical vapor deposition.

[0046] The shielding performance of the product can be further improved by adopting the method of excess half-folding or multi-layer coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com