Lithium ion battery pole plate and preparation method thereof

A lithium ion battery and pole piece technology is applied in the field of lithium ion battery pole pieces and their preparation, which can solve the problems of easily occurring belt breakage, height difference, large thickness, etc., and saves the preparation steps, the preparation method is simple, and the production is reduced. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The preparation method of this heat-shrinkable glue is:

[0062] (1) Prepare foaming adhesive: mix glue, foaming agent and curing agent in proportion and stir;

[0063] (2) The foaming adhesive is coated on the heat-shrinkable substrate, which can be coated with a scraper, and dried after coating; the drying time is 1-3 minutes, and the oven temperature is <85°C;

[0064] (3) Curing (crosslinking by curing agent); temperature is 40-50°C, time >48h; too high temperature will affect the performance of foaming agent, too low temperature will not cure completely; too short curing time will not cure completely;

[0065] (4) Slitting and shipping.

[0066] The invention also relates to the application of the heat-shrinkable glue in preparing lithium-ion battery pole pieces, and the battery pole pieces include positive pole pieces and negative pole pieces.

[0067] The present application also relates to a foam glue 6 used in the above preparation process, which is composed ...

Embodiment 1

[0074] The preparation of embodiment 1 heat-shrinkable glue

[0075] 1. Prepare foaming adhesive: mix acrylate, foaming agent and curing agent in proportion and stir;

[0076] 2. The foaming adhesive is coated on the heat-shrinkable substrate, which can be coated with a scraper, and dried after coating; the drying time is 1 to 3 minutes, and the oven temperature is <85°C;

[0077] 3. Curing (curing agent for cross-linking): the temperature is 40-50°C, and the time is >48h;

[0078] 4. Slitting and shipping. The parameters of the prepared heat shrinkable glue are shown in Table 1.

[0079] Table 1:

[0080]

Embodiment 2

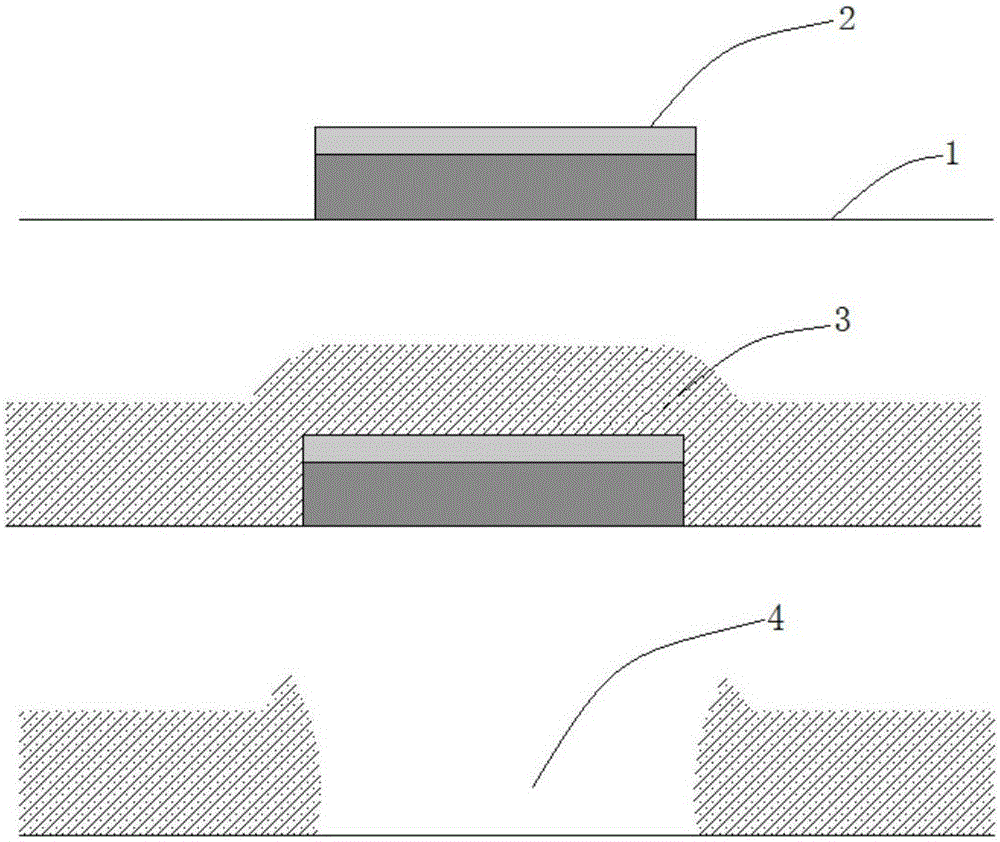

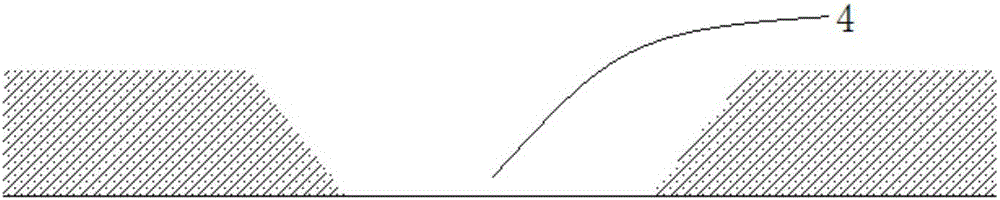

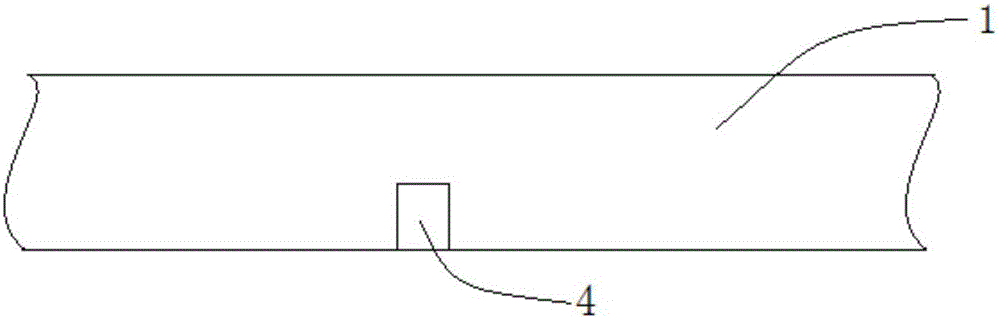

[0081] Example 2 Preparation of battery pole piece

[0082] 1. Design the reserved position of the tab;

[0083] 2. Paste one-way heat-shrinkable glue on the reserved position of the tab of the current collector, and the heat-shrinkable direction of the heat-shrinkable glue is along the length direction of the current collector;

[0084] 3. Coat the active material on the surface of the current collector, heat it to 110-125°C, and the heating rate is >10°C / s; the heat-shrinkable rubber shrinks and curls and then peels off from the current collector, and the active material layer gradually dries;

[0085] 4. The mechanical brush cleans and removes the heat shrinkable rubber and the active substances coated on it;

[0086] 5. Form a reserved position for tabs for welding of tabs.

[0087] The prepared battery pole piece was prepared according to a conventional method to prepare a lithium-ion battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com