Positive electrode additive of lithium battery

An additive and lithium battery technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of general battery self-discharge performance, low battery life, poor cycle performance, etc., to improve self-discharge performance, increase cycle life, The effect of cycle life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

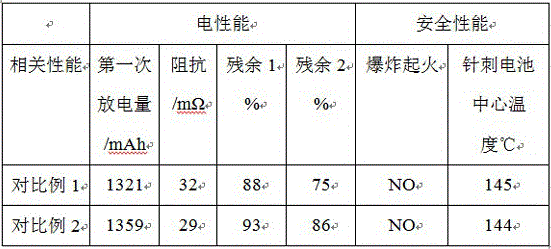

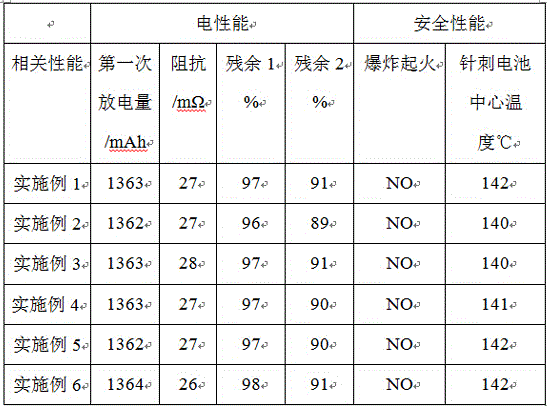

Embodiment 1

[0021] Preparation of modified maleimide additive: 0.09mol melamine, 0.01mol cyanuric acid and 0.02mol cyanamide as initiator, 340mL NMP as solvent, 0.2molN,N'-4,4'-diphenyl Methane-bismaleimide is modified, and the above substances are reacted at 65 ° C for 24 hours to obtain a modified maleimide containing cyanamide with NMP as a solvent, which is used as a lithium battery electrode material composition formula additive.

[0022] 1820gLiCoO 2 , 120g of KS6, 60g of PVDF and 850g of NMP were mixed uniformly to obtain positive electrode slurry. Then add 11.4g of the above additives and mix evenly, then add zirconium beads and mix for 2.5h, pour out the mixture, filter the zirconium beads, and obtain positive electrode slurry.

[0023] Prepare the positive plate according to the standard lithium-ion battery positive plate preparation method, match the standard negative plate, install the standard battery core with a size of 5mm (height) * 59mm (length) * 37mm (width), and pour...

Embodiment 2

[0025] Preparation of modified maleimide additive: 0.01mol melamine, 0.09mol barbituric acid and 0.02mol cyanamide as initiator, 340mL DMF as solvent, 0.2mol reactant N,N'-4,4'- Diphenyl ether-bismaleimide is modified, and the above substances are reacted at 65 ° C for 24 hours to obtain a modified maleimide containing cyanamide with DMF as a solvent, which is used as a lithium battery electrode material composition Additives to recipes.

[0026] 1820gLiCoO 2 , 120g of KS6, 60g of PVDF and 850g of DMF were mixed uniformly to obtain positive electrode slurry. Then add 11.4g of the above additives and mix evenly, then add zirconium beads and mix for 2.5h, pour out the mixture, filter the zirconium beads, and obtain positive electrode slurry.

[0027] Prepare the positive plate according to the standard lithium-ion battery positive plate preparation method, match the standard negative plate, install the standard battery core with a size of 5mm (height) * 59mm (length) * 37mm (w...

Embodiment 3

[0029] Preparation of modified maleimide additive: 0.07mol triaminopyrimidine, 0.03mol cyanuric acid and 0.02mol cyanamide as initiator, 270mL NMP as solvent, 0.2mol reactant N,N'-4,4 '-Phenyl-bismaleimide was modified, and the above substances were reacted at 65°C for 24 hours to obtain a modified maleimide containing cyanamide with NMP as a solvent, which was used as a lithium battery electrode material composition Additives to food formulations.

[0030] 1820gLiMnO 2 , 120g of CGCF, 60g of PVDF and 850g of NMP were mixed uniformly to obtain positive electrode slurry. Then add 11.0 g of the above additives and mix evenly, then add mixed zirconium beads and mix for 2.5 hours, pour out the mixture, filter the zirconium beads, and obtain positive electrode slurry.

[0031] Prepare the positive plate according to the standard lithium-ion battery positive plate preparation method, match the standard negative plate, install the standard battery core with a size of 5mm (height) *...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com