Fiber wood with formaldehyde purification function and production method thereof

A formaldehyde purification and methyl cellulose technology, applied in the field of wood, can solve problems such as threats to people's health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

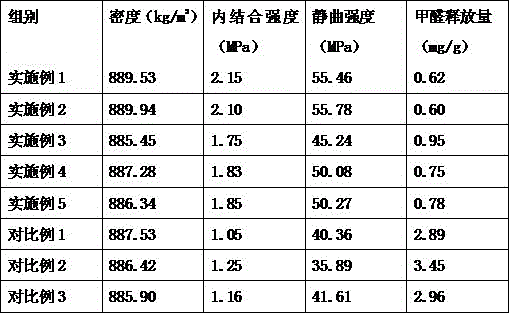

Examples

Embodiment 1

[0030] Embodiment 1: Preparation of a kind of fiber wood with formaldehyde purification function

[0031] The ingredients include 80 parts of wood fiber, 40 parts of bamboo fiber, 4 parts of PVC powder, 2.5 parts of vinyltrimethoxysilane, 3.5 parts of methyl cellulose, 4 parts of sodium silicate, 4 parts of nano-calcium oxide, 10 parts of adhesive, 1 part of phenol polyoxyethylene ether, 4 parts of activated carbon powder, and 4 parts of modified zeolite powder;

[0032] The adhesive is a modified urea-formaldehyde resin, and its preparation method includes: 1) Put formaldehyde into the reactor at one time, add ammonia water to adjust the pH to 7.5, add polyvinyl alcohol and urea for the first time, heat up to 70°C, and keep warm for 60 minutes ;2) Add urea for the second time and melamine for the first time, heat up to 80°C, and keep warm for 50 minutes; 3) Add ammonia water to adjust pH=8.0, add melamine for the second time, keep warm at 85°C for 50 minutes; 4) Cool down to ...

Embodiment 2

[0040] Embodiment 2: Preparation of a kind of fiber wood with formaldehyde purification function

[0041]The ingredients include 65 parts of wood fiber, 25 parts of bamboo fiber, 2.5 parts of PVC powder, 1 part of vinyltrimethoxysilane, 4 parts of methyl cellulose, 3.5 parts of sodium silicate, 3 parts of nano calcium oxide, 6 parts of adhesive, nonyl 1.5 parts of base phenol polyoxyethylene ether, 3.5 parts of activated carbon powder, 4.5 parts of modified zeolite powder;

[0042] Others are the same as embodiment 1.

Embodiment 3

[0043] Embodiment 3: Preparation of a kind of fiber wood with formaldehyde purification function

[0044] The ingredients include 90 parts of wood fiber, 45 parts of bamboo fiber, 4.5 parts of PVC powder, 1.5 parts of vinyltrimethoxysilane, 4.5 parts of methyl cellulose, 4 parts of sodium silicate, 5 parts of nano calcium oxide, 14 parts of adhesive, 2 parts of base phenol polyoxyethylene ether, 5 parts of activated carbon powder, 4 parts of modified zeolite powder;

[0045] The adhesive is a commercially available modified urea-formaldehyde resin, and the modified zeolite is also a commercially available product;

[0046] Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com