Performance evaluation system for integrity of zirconium alloy fuel cladding for nuclear power station under LOCA (Loss-Of-Coolant Accident) working condition

A zirconium alloy fuel and evaluation system technology, applied in nuclear power generation, nuclear engineering, nuclear reactor monitoring, etc., can solve problems such as threats to safety, cladding corrosion, and surface temperature of cladding materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

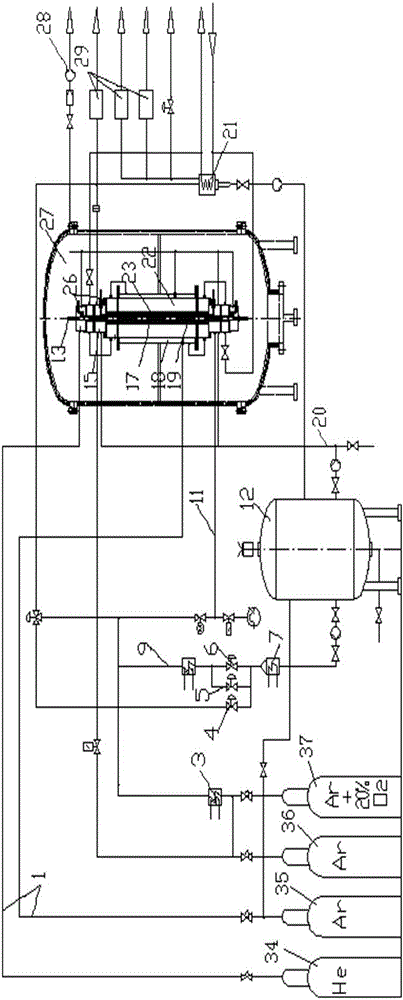

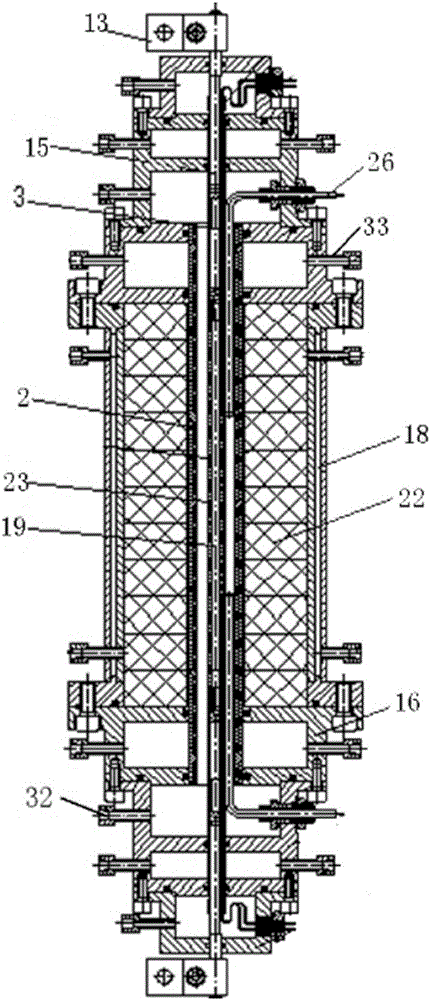

[0027] Such as figure 1 with 2 As shown, this example provides a performance evaluation system for the integrity of the zirconium alloy fuel cladding used in nuclear power plants under LOCA conditions, which mainly includes a reaction device, a working gas distribution system 1, a mixed gas supply device, a gas separator 21, gas components and Content analysis system 29 (including hydrogen analyzer), water quenching system 20, pressure measuring device and vacuum system 28.

[0028] The reaction device is used to evaluate the corrosion performance of the cladding 23 in high-temperature steam. The reaction device includes a sample chamber for providing a space for high-temperature water vapor to react with the cladding 23, a heating electrode 13 for heating the cladding 23, and a heating electrode 13 for heating the cladding 23. As a temperature measuring device for measuring the temperature of the inner wall and outer wall of the cladding 23, the sample chamber includes a qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com