Average current control circuit and average current control method

A technology of average current control and average current, applied in control/regulation systems, conversion of DC power input to DC power output, electrical components, etc. It can solve the problem of limiting the application of average current control circuits, increasing circuit design complexity, and not applicable High-voltage application circuit and other problems, to achieve the effect of improving the current detection scheme, reducing the design difficulty, and excellent anti-noise performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

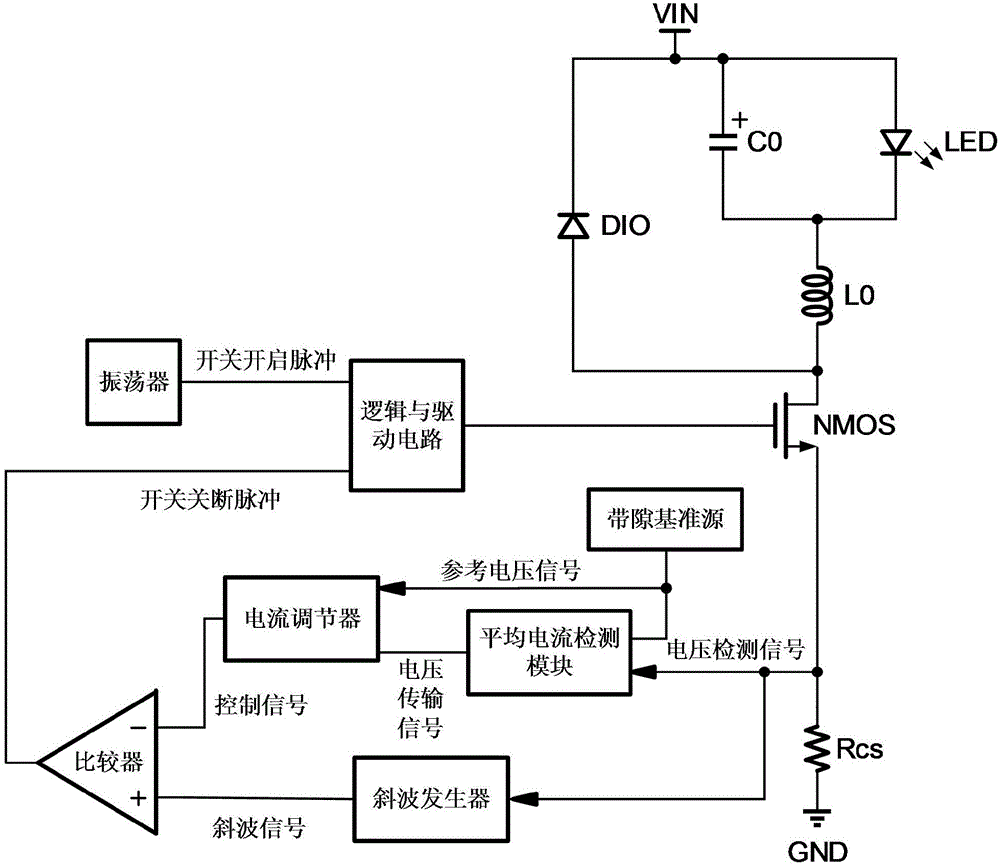

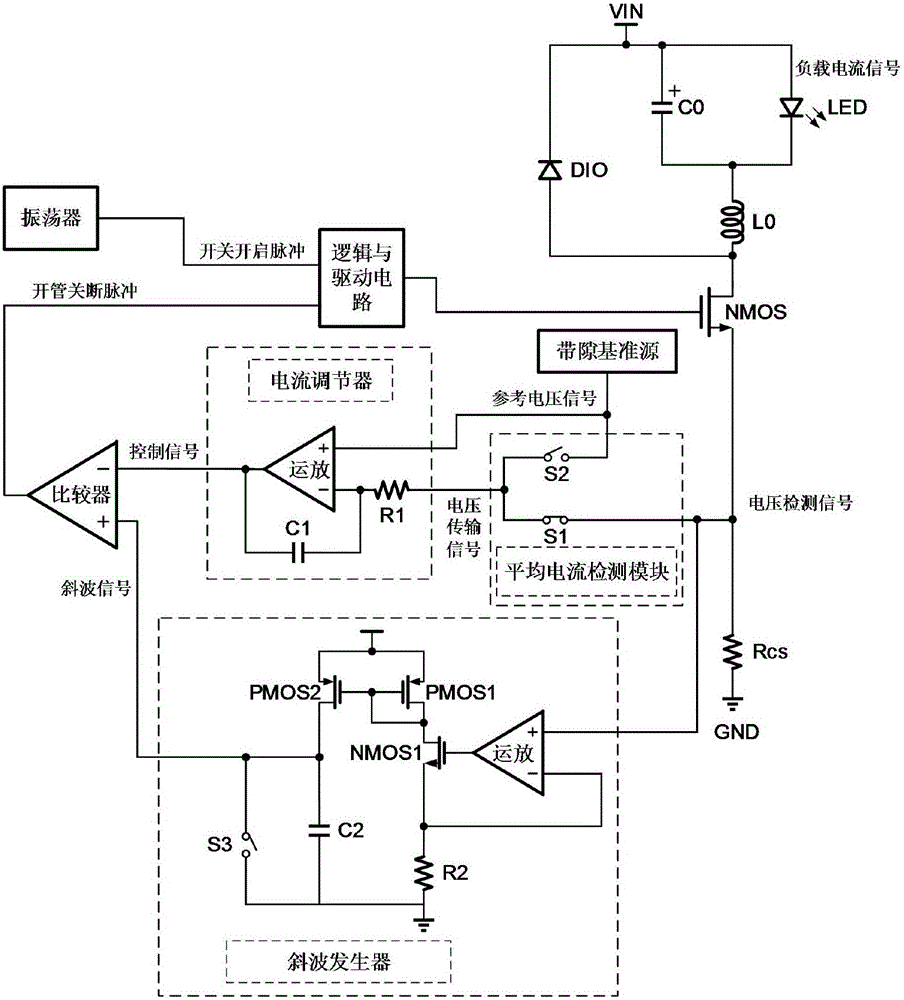

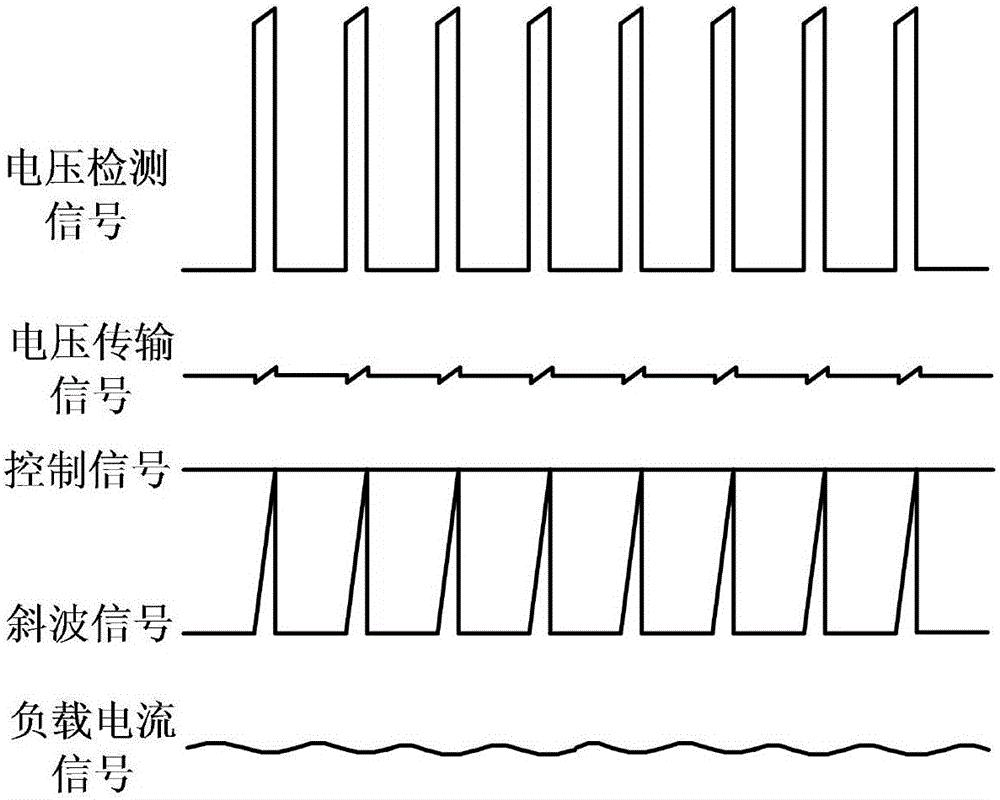

[0058] This embodiment first describes the main frame structure of an average current control circuit provided by the present invention and the corresponding average current control method.

[0059] Such as figure 1 As shown, the average current control circuit includes load LED, power switch NMOS, inductor L0, capacitor C0, detection resistor Rcs, bandgap reference source, oscillator; comparator and logic and drive circuit;

[0060] In addition, the control circuit also includes:

[0061] The current detection module is connected to the source end of the NMOS of the power switch and the non-ground end of the detection resistor Rcs during the turn-on period of the power switch to detect the current flowing through the NMOS of the power switch. The bandgap reference source;

[0062] The ramp generator is connected to the source end of the NMOS of the power switch and the non-ground end of the detection resistor Rcs during the turn-on period of the power switch to generate a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com