Novel Klebsiella sp. or Candida sp. strain, and microbial fuel cell containing same

A Klebsiella and Candida technology, which is applied in the field of novel Klebsiella or Candida strains and microbial fuel cells containing the same, can solve problems such as no reports being published, and achieve high-efficiency wastewater treatment Fields, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1: Screening and identification of bacterial strains for microbial fuel cells

[0056] To screen strains for microbial fuel cells present in anaerobic sludge, strains for microbial fuel cells were screened from the biofilm formed on the anode (Anode) after operating the microbial fuel cell using the anaerobic sludge and identify.

[0057] Specifically, the microbial fuel cell utilizes Singlechambersystems (Anode: carbonfelt (9×14 cm) as an anode electrode obtained by pretreatment at 450°C for 30 minutes; air-cathode (air-cathode, ODE75, MEET , Korea); Protonexchangemembrane: Nafion117 (Dupont, USA); Reactor: 7×15×10cm (L×H×W) persingle chamber (1-Lvolume); Voltagemonitoringsystem: digitalmultimeter (GL220, Japan); Line: titaniumwire (Sigma, USA )), wherein the anode electrode and cathode electrode included in the microbial fuel cell are connected to a platinum electrode and a 100Ω external resistor. In addition, as a culture solution for microbial fuel cells, ...

Embodiment 2

[0070] Example 2: Evaluation of microbial fuel cells utilizing Klebsiella sp. IR21 strain or Candida sp. IR11

[0071] The results of microbial fuel cells containing the Klebsiella IR21 or Candida IR11 strains identified in Example 1 were run and evaluated.

Embodiment 2-1

[0072] Example 2-1: Microbial culture environment and voltage changes

[0073] Specifically, among the colonies obtained in Example 1, bacterial cells were obtained from colonies corresponding to Klebsiella IR21 or Candida IR11 strains, inoculated into the inoculum culture solution, and then cultured to obtain Obtain cultures.

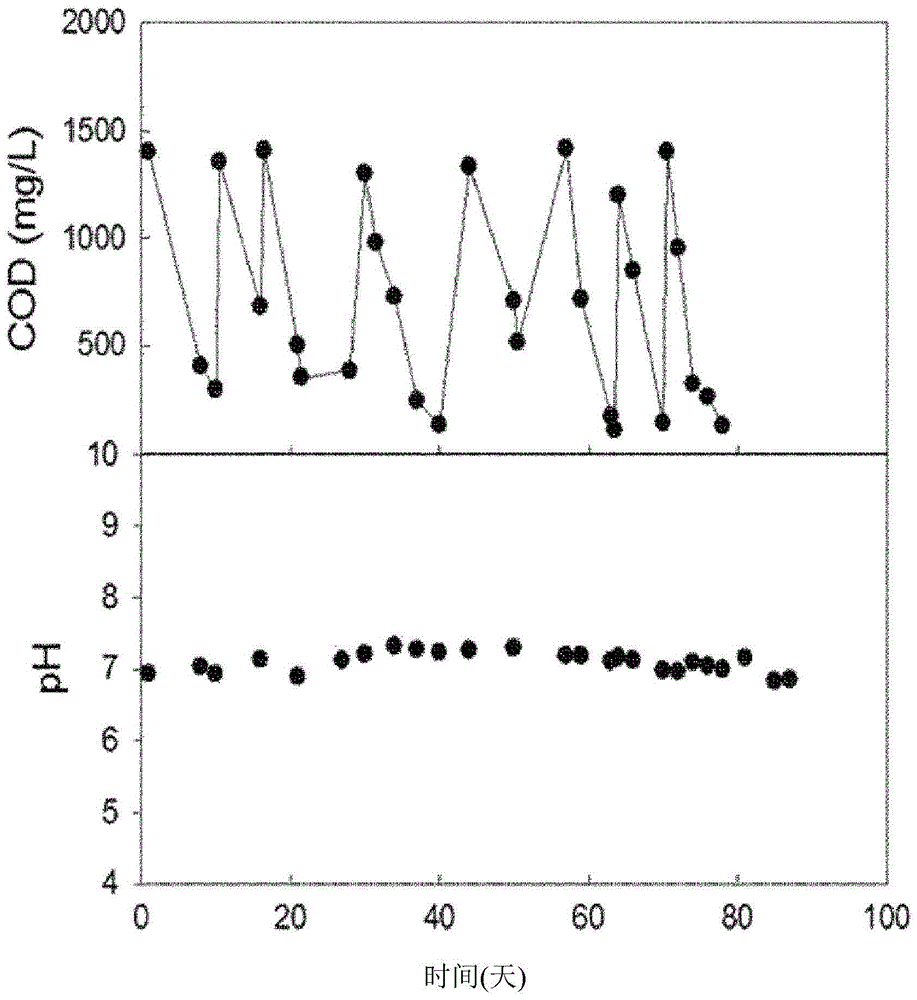

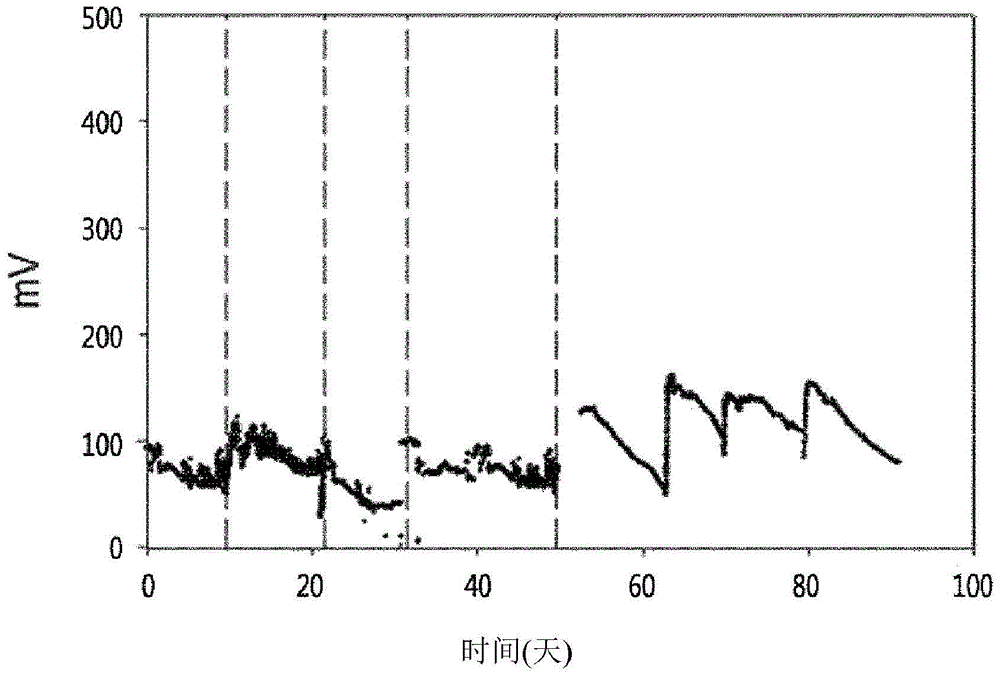

[0074] After mixing the culture and anaerobic sludge, the mixture was used as an initial inoculum source, and as a substrate a glucose and acetate mixture (1:1, w / w), or COD is about 15,000mg / L the waste water in the hydrogen production process, in addition, by the method identical with described embodiment 1, run microbial fuel cell ( Figure 3a , 3b , 4a and 4b).

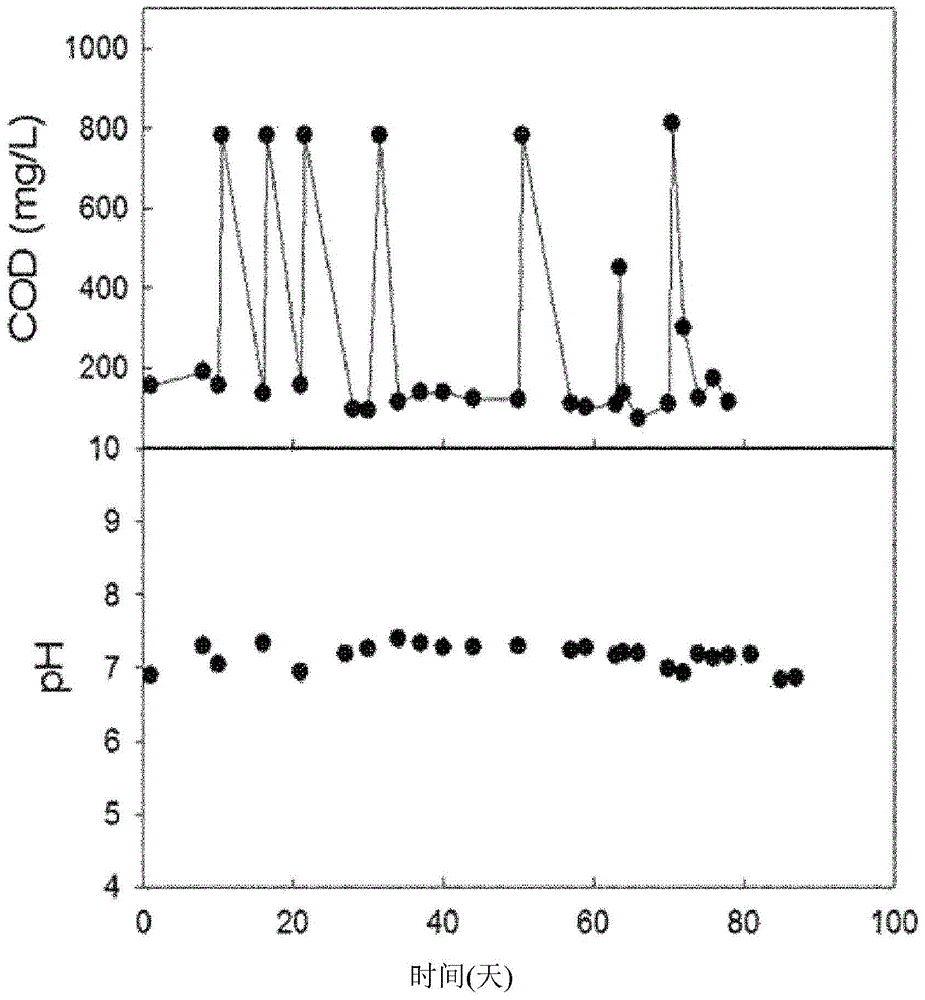

[0075] In addition, the culture and anaerobic sludge were mixed, and the mixture was used as an initial inoculum source, and a glucose and acetate mixture (1:1, w / w), or COD is about the waste water in the biogas production process of 500mg / L, in addition, by the same method as descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com