Fermented buccal tobacco

A snus and shredded tobacco technology, applied in tobacco, tobacco processing, application, etc., can solve the problems of restricting the raw material space of smokeless tobacco products, not involving the fermentation and treatment process of tobacco raw materials, and strong spicy taste, etc., to achieve the elimination of green impurities The effect of reducing gas and irritation, improving taste comfort, and rich and mellow aroma quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

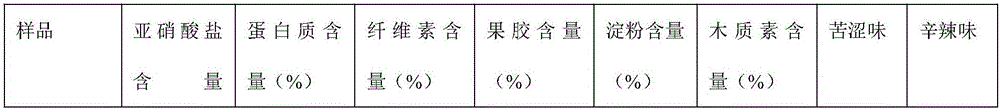

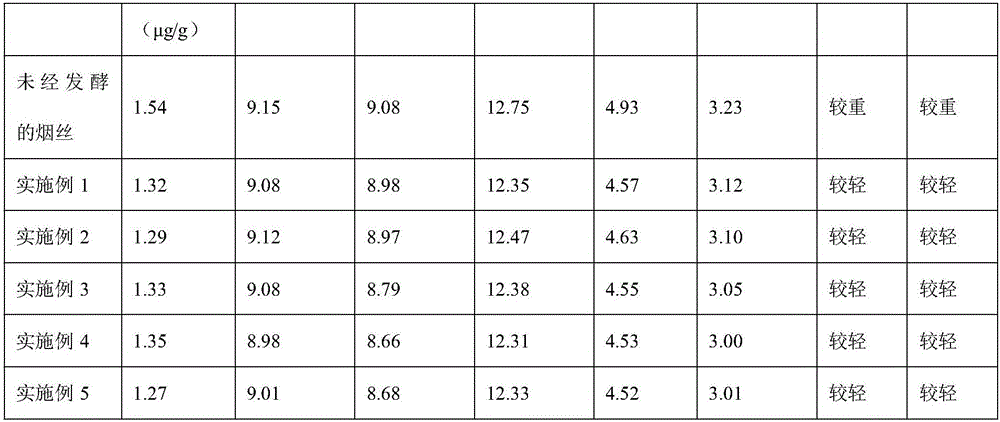

Examples

Embodiment 1

[0040] The present embodiment prepares a kind of shredded tobacco particle, and its preparation method comprises the following steps:

[0041] S1. Prepare the tobacco leaf formula group: prepare the tobacco leaf group according to the mass ratio of flue-cured tobacco: burley tobacco at 2:4;

[0042] S2. Tobacco leaf treatment: wash the tobacco leaves with water, remove surface dust, shake dry slightly, remove excess water, and shred;

[0043] S3. Fermentation of shredded tobacco: prepare the inoculum, and ferment after inoculation according to the inoculation amount of 1g inoculum / 100g shredded tobacco. The fermentation conditions are: keep the temperature at 45°C during the fermentation process, and the fermentation time is 15 days; the scientific fermentation process not only obtains Good snus flavor with reduced nitrite content.

[0044] The composition of the inoculum is fructose syrup: protein peptide: bacterial strain: distilled water mass ratio=50g: 5g: 0.1g: 250g; the b...

Embodiment 2

[0048] The present embodiment prepares a kind of shredded tobacco particle, and its preparation method comprises the following steps:

[0049] S1. Prepare the tobacco leaf formula group: prepare the tobacco leaf group according to the mass ratio of flue-cured tobacco: burley tobacco: air-dried tobacco at 1:1:1;

[0050] S2. Tobacco leaf treatment: wash the tobacco leaves with water, remove surface dust, shake dry slightly, remove excess water, and shred;

[0051] S3. Fermentation of shredded tobacco: prepare the inoculum, and ferment after inoculation according to the inoculation amount of 1g inoculum / 100g shredded tobacco. The fermentation conditions are: keep the temperature at 45°C during the fermentation process, and the fermentation time is 15 days; the scientific fermentation process not only obtains Good snus flavor with reduced nitrite content.

[0052] The composition of the inoculum is fructose syrup: protein peptide: bacterial strain: distilled water mass ratio=50g...

Embodiment 3

[0056] This embodiment provides a method for preparing shredded tobacco suitable for snus, comprising the following steps:

[0057] S1. Prepare the tobacco leaf formula group: prepare the tobacco leaf group according to the mass ratio of flue-cured tobacco: burley tobacco: air-dried tobacco at 1:1:1;

[0058] S2. Tobacco leaf treatment: wash the tobacco leaves with water, remove surface dust, shake dry slightly, remove excess water, and shred;

[0059] S3. Fermentation of shredded tobacco: prepare the inoculum, and ferment after inoculation according to the inoculation amount of 10g inoculum / 100g shredded tobacco. The fermentation conditions are as follows: the fermentation process keeps the controlled temperature at 35°C, and the fermentation time is 20 days; the scientific fermentation process not only obtains Good snus flavor without producing excessive nitrite.

[0060] The composition of the inoculum is fructose syrup: protein peptide: strain: mass ratio of distilled wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com