Polycrystalline silicon and iron alloy water-cooling heat-resistant cooling ingot mold

A ferroalloy and polysilicon technology, which is applied in the field of crystal ingot molds for casting, can solve problems such as slow heat exchange speed, adhesion, and unfixed size, and achieve the effects of fast heat exchange speed, reduced operating costs, and guaranteed service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

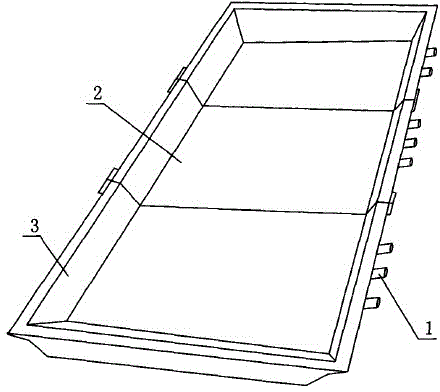

[0011] Such as figure 1 As shown, a water-cooled heat-resistant cooling ingot mold for polysilicon and ferroalloy includes a groove-shaped ingot mold body, and a water-cooling pipeline 1 is arranged at the bottom of the groove-shaped ingot mold body. Since the present invention arranges water-cooling pipes at the bottom of the groove-shaped ingot mold body, after a large amount of heat released by metal cooling and solidification is absorbed by the ingot mold body, it is not only transmitted to the air through heat radiation, but also through the large specific heat in the water-cooling pipes. The water quickly takes away the heat, and the heat exchange speed is extremely fast, so the temperature of the ingot mold drops quickly, and the parts in contact with the liquid metal can ensure the independence of its metallographic structure, and it is not easy to cause adhesion, slipping, and falling blocks. Phenomena such as ensuring the service life of the ingot mold, but also i...

Embodiment 2

[0013] Such as figure 1 As shown, a water-cooled heat-resistant cooling ingot mold for polycrystalline silicon and ferroalloy includes a groove-shaped ingot mold body. It is composed of 2 movable connections with the middle ingot module. The trough-shaped ingot mold body is composed of the end ingot module and the middle ingot module. The large body is turned into a combined block, which is very convenient to disassemble and reassemble ingots with different needs, which improves the utilization rate of the equipment, and further Reduced business operating costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com