Machining technology for small deep step hole of high-precision medical apparatus and instrument

A technology of medical equipment and processing technology, which is applied in the field of high-precision processing technology of medical equipment, can solve the problems of high scrap rate, high maintenance cost, expensive tool consumables, low production efficiency, etc., and achieve excellent processing roughness and rough inner wall of the hole low degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

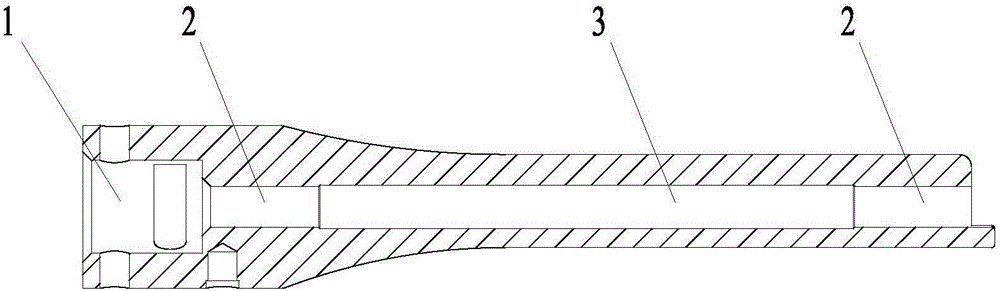

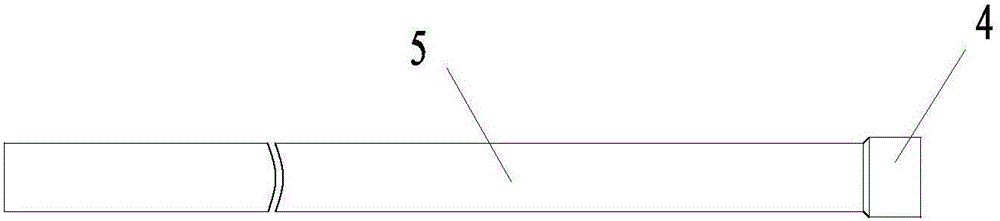

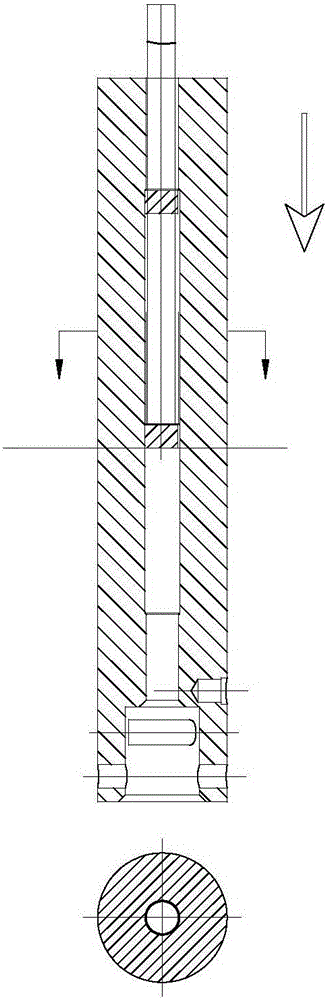

[0036] combine Figure 1 to Figure 4 As shown, the present embodiment is a medical guide cylinder, which is used as a mounting fixture for surgical tools such as Kirschner wires, drill bits, and reamers. A through hole is set in the middle of the guide cylinder, and the through hole includes the end through hole 1 of the cutting edge part, the middle through hole The hole 2 and the bore part 3, the intermediate through hole 2 and the bore part 3 form steps due to the difference in diameter. The processing of the guide cylinder adopts a kind of high-precision medical device small deep step hole processing technology of the present invention, which comprises the following steps:

[0037] (1) Prepare the product blank and process the blank. The length of the processed blank is 160mm and the diameter is 30mm. The designed length after the end face is 158mm, and the maximum outer diameter after the first outer circle is 28mm. .

[0038] (2) Drill the middle through hole: Clamp th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com