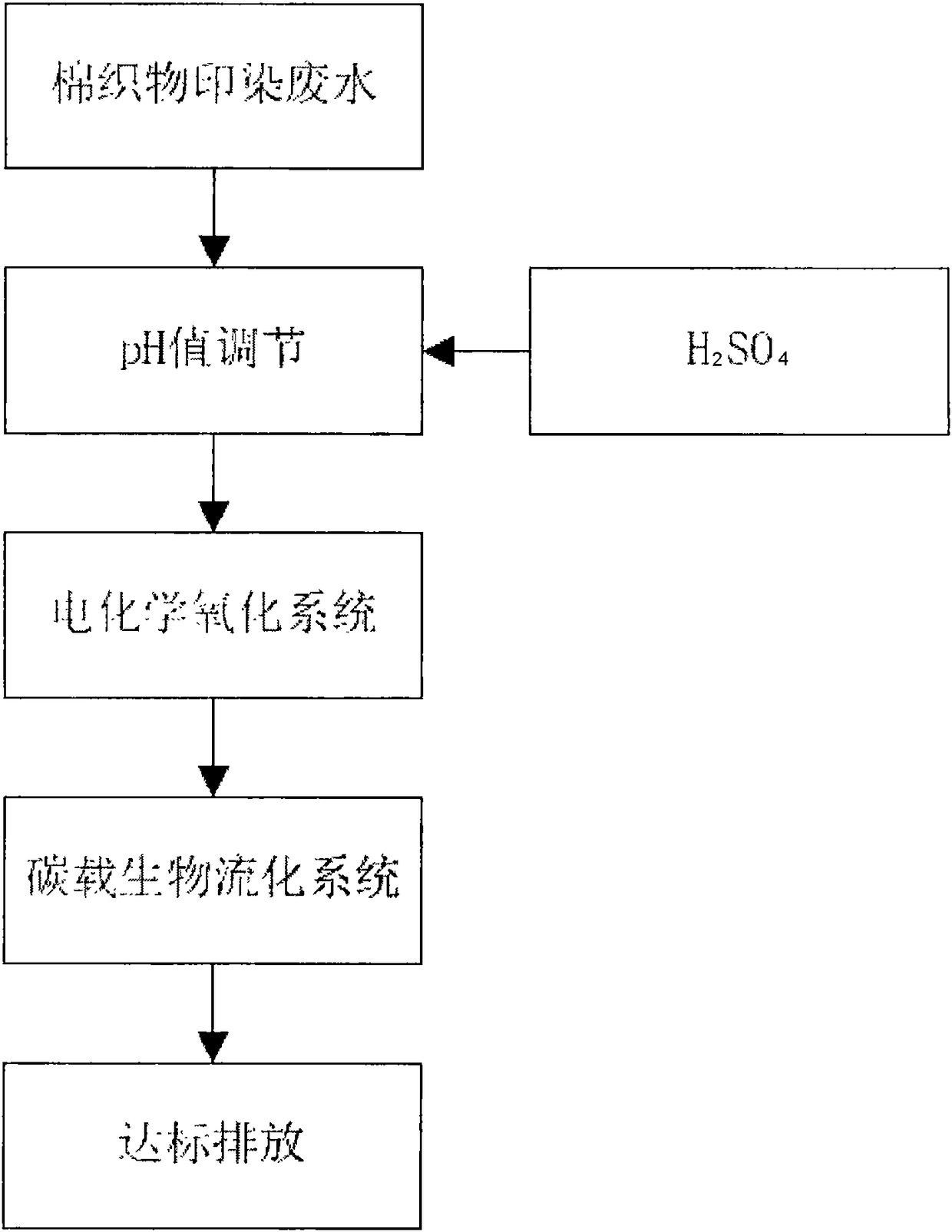

A kind of cotton fabric printing and dyeing wastewater treatment method

A technology of printing and dyeing wastewater and treatment method, which is applied in the direction of textile industry wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. Biochemical feasibility, ensuring stable emission standards, and improving the effect of reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

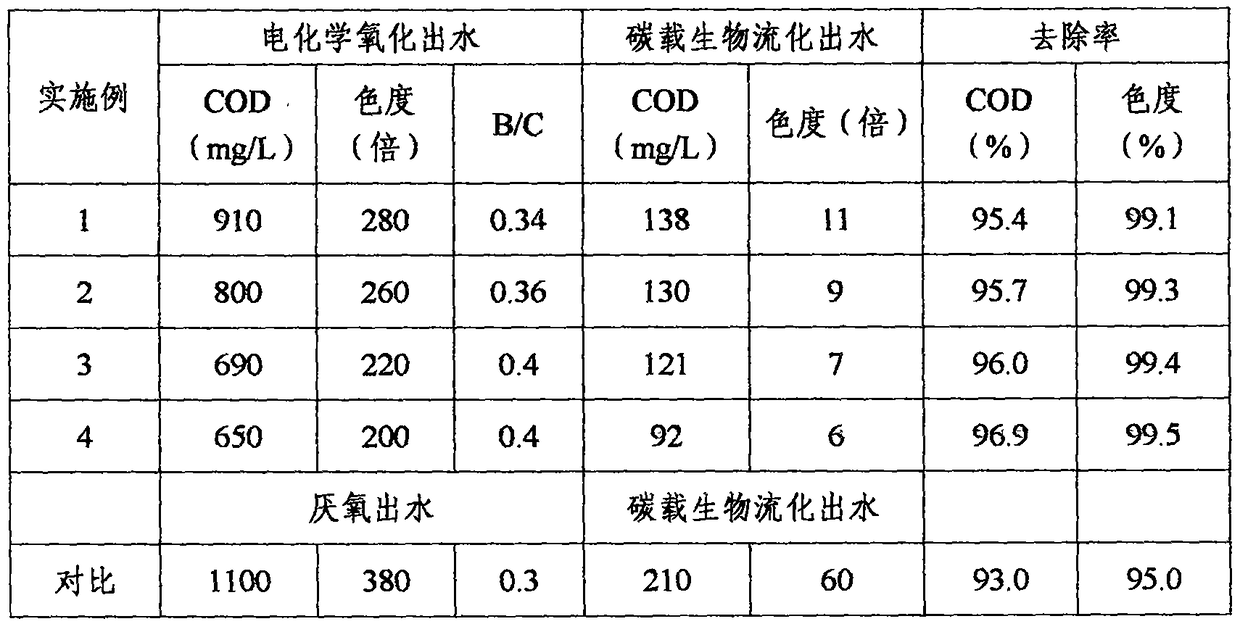

Embodiment 1

[0032] In the electrochemical oxidation system, a boron-doped diamond electrode is used as the anode, and ordinary stainless steel is used as the cathode. Take 2L of cotton fabric printing and dyeing wastewater to adjust the pH value to 9, pump it into the electrochemical oxidation system, turn on the DC power supply, and set the current density to 200A / m 2 , turn on the circulation pump, and carry out the electrochemical oxidation reaction, and the reaction time is 3 hours. After the reaction was completed, it was measured that the COD in the water decreased from 3000mg / L to 910mg / L, the chromaticity decreased from 1200 times to 280 times, and the B / C increased from 0.1 to 0.34.

[0033] The electrochemically oxidized wastewater is continuously pumped into the carbon-loaded biological fluidization system for biodegradation. Among them, the activated carbon in the carbon-loaded biological fluidization system is shell carbon, and its content is maintained at about 450mg / L, the...

Embodiment 2

[0035]In the electrochemical oxidation system, a titanium-plated tin dioxide electrode is used as the anode, and 316L stainless steel is used as the cathode. Take 2L of cotton fabric printing and dyeing wastewater and adjust the pH value to 10, pump it into the electrochemical oxidation system, turn on the DC power supply, set the current density to 300A / m2, turn on the circulation pump, and carry out the electrochemical oxidation reaction for 2 hours. After the reaction was completed, it was measured that the COD in the water decreased from 3000mg / L to 800mg / L, the chromaticity decreased from 1200 times to 260 times, and the B / C increased from 0.1 to 0.36.

[0036] The electrochemically oxidized wastewater is continuously pumped into the carbon-loaded biological fluidization system for biodegradation. Among them, the activated carbon in the carbon-loaded biological fluidization system is shell carbon, and its content is maintained at about 350mg / L, the reaction temperature is...

Embodiment 3

[0038] In the electrochemical oxidation system, a titanium electrode plated with tin dioxide is used as the anode, and ordinary stainless steel is used as the cathode. Take 2L of cotton fabric printing and dyeing wastewater and adjust the pH value to 8, pump it into the electrochemical oxidation system, turn on the DC power supply, set the current density to 350A / m2, turn on the circulation pump, and carry out the electrochemical oxidation reaction for 2 hours. After the reaction was completed, it was measured that the COD in the water decreased from 3000mg / L to 690mg / L, the chromaticity decreased from 1200 times to 220 times, and the B / C increased from 0.1 to 0.4.

[0039] The electrochemically oxidized wastewater is continuously pumped into the carbon-loaded biological fluidization system for biodegradation. Among them, the activated carbon in the carbon-loaded biological fluidization system is coal-based carbon, and its content is maintained at about 300mg / L, the reaction t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com