A kind of biochemical treatment method of organosilicon wastewater

A biochemical treatment, organosilicon technology, applied in multi-stage water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of complex composition of organosilicon wastewater, high treatment cost, difficult biochemical, etc., to improve the catalytic effect , strengthen the treatment effect, the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

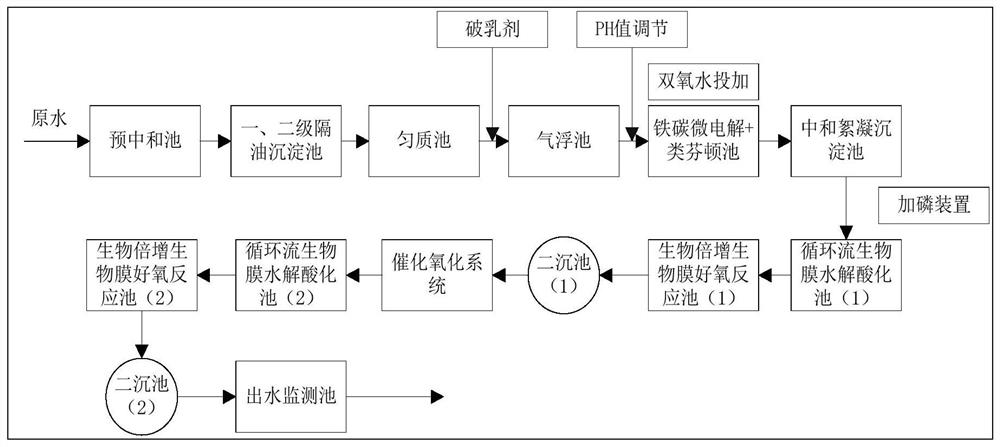

Method used

Image

Examples

Embodiment 1

[0055] Get the water in the homogeneous pool, the water quality table is as follows:

[0056] serial number index value 1 pH 8.5 2 COD 1123mg / L

[0057] 1) After the organic silicon wastewater is pretreated, the pH value is adjusted to 2 with acid, so that the COD concentration of the organic silicon wastewater is controlled at 1123 mg / L.

[0058] 2) Put the pretreated wastewater into the iron-carbon micro-electrolysis + Fenton-like advanced oxidation pool, add hydrogen peroxide with a concentration of 25%, and the mass ratio of ferrous iron is twice that of hydrogen peroxide.

[0059] 3) Step 2) After the pH value of the effluent is adjusted to 8, it enters the flocculation and sedimentation tank, and polyacrylamide with a concentration of 5 mg / L is added, and the sedimentation is clarified for 60 minutes, and CODCr is detected. At this time, the detection value of COD was 698mg / L, the average removal rate was 37.8%, and the B / C increased to ...

Embodiment 2

[0069] Get the water in the homogeneous pool, the water quality table is as follows:

[0070] serial number index value 1 pH 8.5 2 COD 1123mg / L

[0071] 1) After the organic silicon wastewater is pretreated, the pH value is adjusted to 2.5 with acid, so that the COD concentration of the organic silicon wastewater is controlled at 1123 mg / L.

[0072] 2) Put the pretreated wastewater into the iron-carbon micro-electrolysis + Fenton-like advanced oxidation pool, add hydrogen peroxide with a concentration of 30%, and the mass ratio of ferrous iron is twice that of hydrogen peroxide.

[0073] 3) Step 2) After the effluent water is adjusted to 8.8 after the pH value, it enters the flocculation sedimentation tank, and polyacrylamide with a concentration of 5 mg / L is added, the sedimentation is clarified for 60 minutes, and CODCr is detected. At this time, the detection value of COD was 620mg / L, the average removal rate was 44.8%, and the B / C increase...

Embodiment 3

[0083] Get the water in the homogeneous pool, the water quality table is as follows:

[0084] serial number index value 1 pH 8.5 2 COD 1123mg / L

[0085] 1) After the organosilicon wastewater is pretreated, acid is used to adjust the pH value to 3, so that the COD concentration of the organosilicon wastewater is controlled at 1123 mg / L.

[0086] 2) Put the pretreated wastewater into the iron-carbon micro-electrolysis + Fenton-like advanced oxidation pool, add hydrogen peroxide with a concentration of 35%, and the mass ratio of ferrous iron is twice that of hydrogen peroxide.

[0087] 3) Step 2) After the effluent is adjusted to a pH value of 9, it enters the flocculation sedimentation tank, and polyacrylamide with a concentration of 5mg / L is added, and the sedimentation is clarified for 70 minutes, and CODCr is detected. At this time, the detection value of COD was 607mg / L, the average removal rate was 46.4%, and the B / C increased to 0.327mg / L....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com