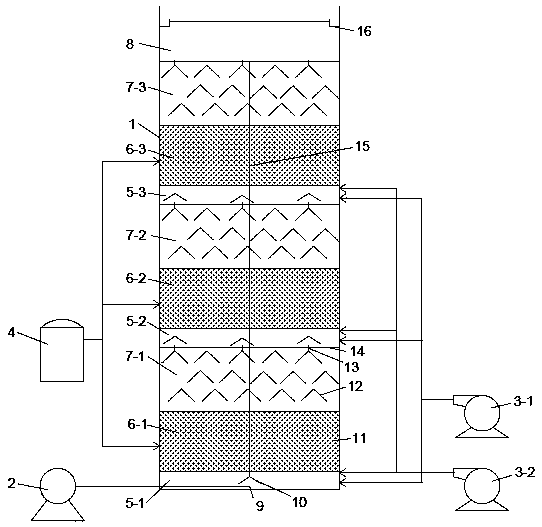

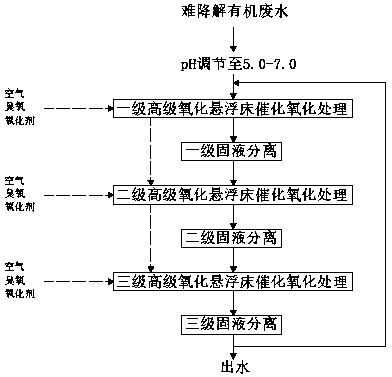

Advanced oxidation multistage suspension bed reaction device and process

A reaction device and advanced oxidation technology, applied in the direction of oxidized water/sewage treatment, multi-stage water/sewage treatment, multi-stage water treatment, etc., can solve the problem of reduced utilization efficiency of hydrogen peroxide and ozone, low ozone utilization efficiency, and lower overall system Efficiency and other issues, to achieve the effect of improving energy and chemical utilization efficiency, improving energy and chemical utilization efficiency, and improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The production wastewater of a coal chemical enterprise has a raw water COD of 2700 mg / L and a pH value of 8.2. Using an advanced oxidation multi-stage suspension bed reaction device and process treatment of the present invention, the pH of the raw water is adjusted to 5.0; it enters the first-stage suspension bed reaction unit for treatment, and the catalyst particles are 50 mm in diameter and carry Fe 2 o 3 Activated carbon, air aeration at the bottom, the residence time of wastewater is 40 min; then enter the secondary suspension bed reaction unit for treatment, the catalyst particles are 40 mm in size and carry Fe 2 o 3 、TiO 2 Activated carbon, air aeration at the bottom, the residence time of wastewater is 40 min; then enter the three-stage suspended bed reaction unit for treatment, the catalyst particles are 25 mm in size and carry TiO 2 Activated carbon, air aeration at the bottom, hydrogen peroxide dosing concentration 10 mg / L, wastewater residence time 40 mi...

Embodiment 2

[0055] The production wastewater of a chemical synthesis pharmaceutical company, the raw water COD is 19800 mg / L, and the pH value is 6.5. Using an advanced oxidation multi-stage suspension bed reaction device and process treatment of the present invention, the pH of the raw water is adjusted to 5.0; it enters the first-stage suspension bed reaction unit for treatment, and the catalyst particles are 50 mm in diameter and carry Fe 2 o 3 Activated carbon, exposed to ozone at the bottom, the wastewater residence time is 50 min; then enters the secondary suspension bed reaction unit for treatment, the catalyst particles are 30 mm particle size loaded TiO 2 Activated carbon, ozone exposure at the bottom, hydrogen peroxide dosing concentration 20 mg / L, wastewater residence time 30 min; then enter the three-stage suspended bed reaction unit for treatment, catalyst particles with a particle size of 15 mm loaded with PtO 2 , IrO 2 Activated carbon, ozone exposure at the bottom, hydro...

Embodiment 3

[0057] Reverse osmosis concentrated water from a reclaimed water plant, raw water COD 820 mg / L, pH 7.1. Using an advanced oxidation multi-stage suspension bed reaction device and process treatment of the present invention, the pH of the raw water is adjusted to 5.5; it enters the first-stage suspension bed reaction unit for treatment, and the catalyst particles are 50 mm in diameter and carry Fe 2 o 3 Activated carbon, exposed to ozone at the bottom, the wastewater residence time is 60 minutes; then enters the secondary suspension bed reaction unit for treatment, the catalyst particles are 25 mm in diameter and carry Fe 2 o 3 、TiO 2 Activated carbon, ozone exposure at the bottom, hydrogen peroxide dosing concentration 15mg / L, wastewater residence time 60 min, effluent COD 45 mg / L after final treatment, removal rate 94.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com