Preparation method of natural high-concentration jasmine tea essence

A jasmine tea, high-concentration technology, applied in the direction of essential oil/fragrance, fat production, etc., can solve the problems of low product concentration, high transportation cost, incomplete aroma, etc., and achieve the effect of overcoming low concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

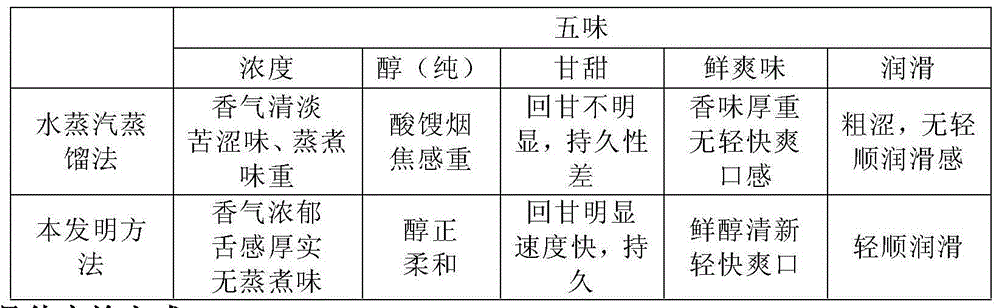

Image

Examples

Embodiment 1

[0029] (1) Use a pulverizer to crush the mold-free and clean jasmine tea leaves to 20-60 meshes, and mix them with water at a ratio of 1:16 by weight to make component A jasmine tea slurry with fluidity. The jasmine tea used in this embodiment The tea leaves are Fujian Longtuanzhu Jasmine Tea or Fujian Zhenghe Jasmine Silver Needle;

[0030] (2) The obtained component A jasmine tea slurry is extracted by the SCC (spinning cone distillation column) method, and the parameters are: the flow rate of component A is 400L / H, the feed temperature is 98°C, and the temperature difference between the feed temperature and the system is -2°C, the system temperature is 100°C, and the external extraction rate is 7.5-8.5%; two parts are obtained, namely, component B jasmine tea extract and component C jasmine tea slurry, and the secondary SCC extraction is carried out for component B , the parameters are: the flow rate of component B is 700L / H, the feed temperature is 98°C, the temperature di...

Embodiment 2

[0034] Same as Example 1, the difference is that the raw material used in this embodiment is Jinhua jasmine tea, the feed temperature of the material is reduced in step (2) and the temperature difference between the feed temperature and the SCC system temperature is increased, and the obtained component A jasmine The tea slurry is extracted by the SCC (Spinning Cone Column) method, and the working parameters of the SCC system are set. The specific parameters are: the system temperature is 100°C; the feed rate is 400L / H; the material temperature is 95°C; The temperature difference of the system is -5°C; the external extraction rate is 7.5-8.5%. The same effect can be achieved by changing the feed temperature and the temperature difference between the feed temperature and the SCC system temperature.

Embodiment 3

[0036]Same as Example 2, except that the raw material used in this example is Suzhou jasmine tea. In step (3), the type and amount of enzyme added and the enzymolysis time are reduced, and the temperature of component F is adjusted to 40-45°C. Add 0.15% of the dry weight of tea leaves for enzymolysis, pH value 6.5, heat preservation and stirring for 3.5 hours; reducing the amount of enzyme added and enzymolysis time can achieve the same effect, shorten the processing cycle and increase production out, improve production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com