Breeding method of high-concentration CO2-tolerant microalgae species

A technology of CO2 and microalgae, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of single-gene knockout mutants unable to grow normally, achieve increased carotenoid content, high efficiency, The effect of less work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A strain of Chlorella (Chlorella sorokiniana) was isolated and screened from the natural environment of Chongming Island, Shanghai. According to the identification of molecular biology, the homologous similarity between the algae and the algae in the known database is 99%. The algal strain was placed in 10% CO 2 conditions for adaptive evolution. The culture medium is BG11 medium.

[0033] Adaptive evolution culture conditions: the initial inoculation density of microalgae is 0.02g / L, the temperature is 28°C; the apparent ventilation rate is 0.26cm / s; the light intensity is about 95μmol photons (photons) / m 2 / s, continuous light (that is, the light-dark cycle ratio is 24 hours / 0 hours), and the culture system is 300ml. In order to obtain enough Chlorella as algal species for the next evolution cycle, the culture time of the first cycle was set to 7 days, and then the evolution time of each cycle was set to 3 days. Three parallel experiments were set up for each grou...

Embodiment 2

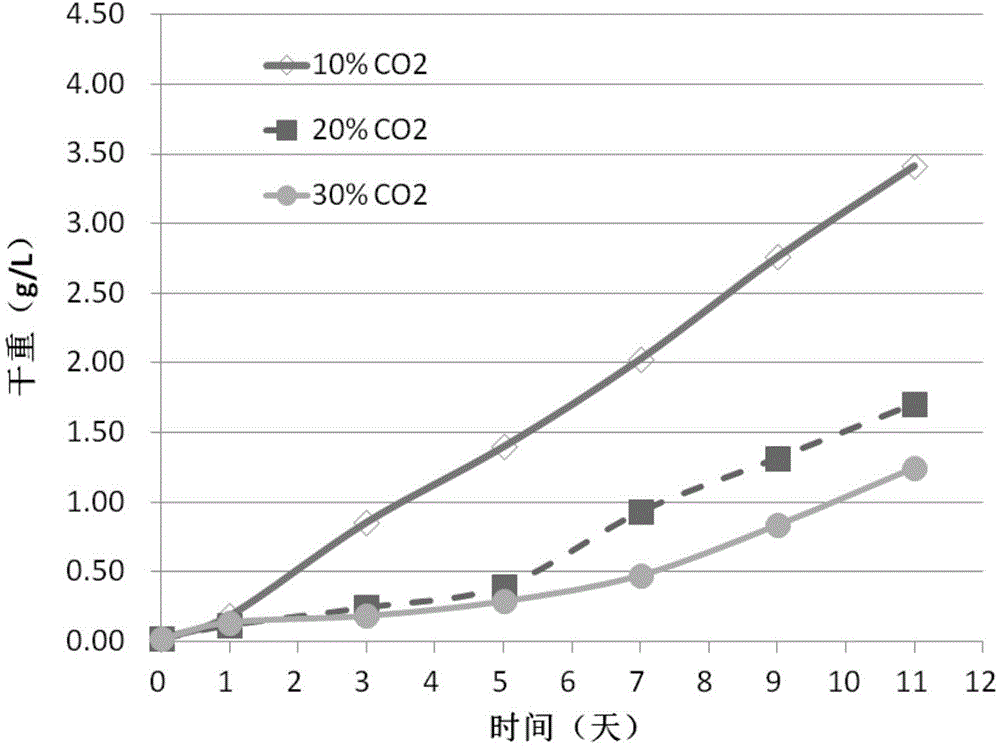

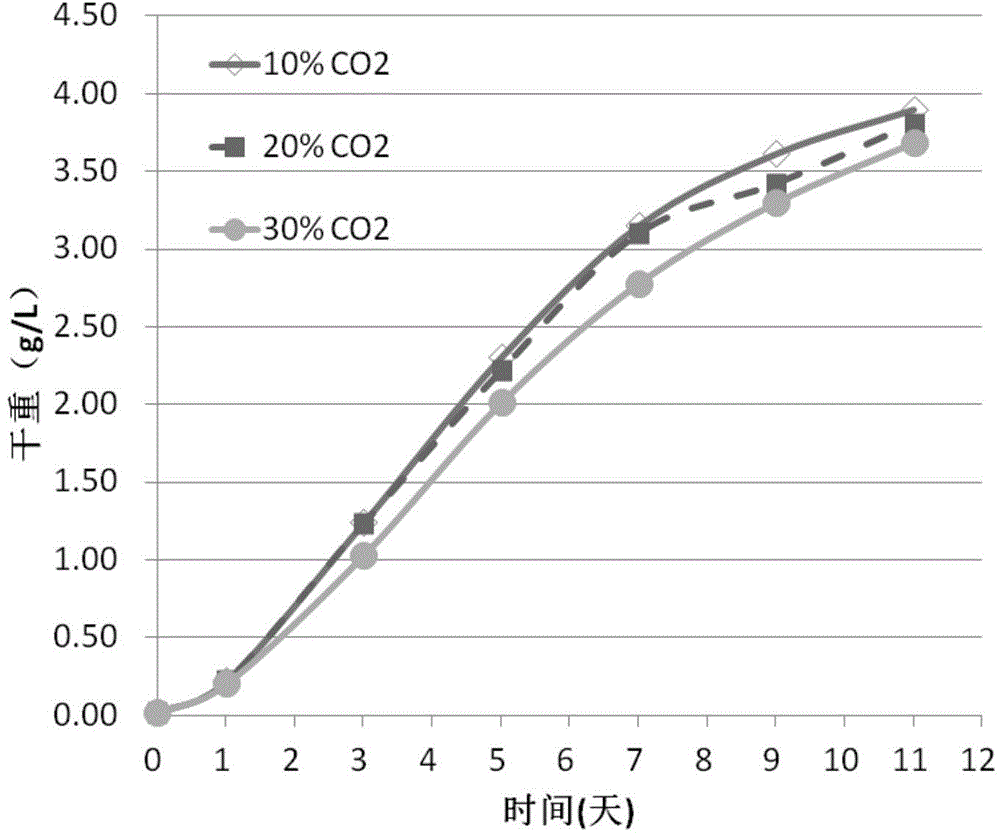

[0044] Unevolved Chlorella in 20% CO 2 Conditions for adaptive evolution (other conditions are the same as in Example 1). Using 20% CO 2 The evolutionary strains obtained after evolution under the conditions of 10% and 20% CO respectively 2 and 30% after 11 days of cultivation, its dry weight can reach 3.0g / L (such as Figure 5 shown). Compared with the dry cell weight of unevolved algal strains (such as figure 1 shown), at 10% and 20% CO 2 Conditioned growth was enhanced, with 85% and 141% increases in dry cell weight, respectively.

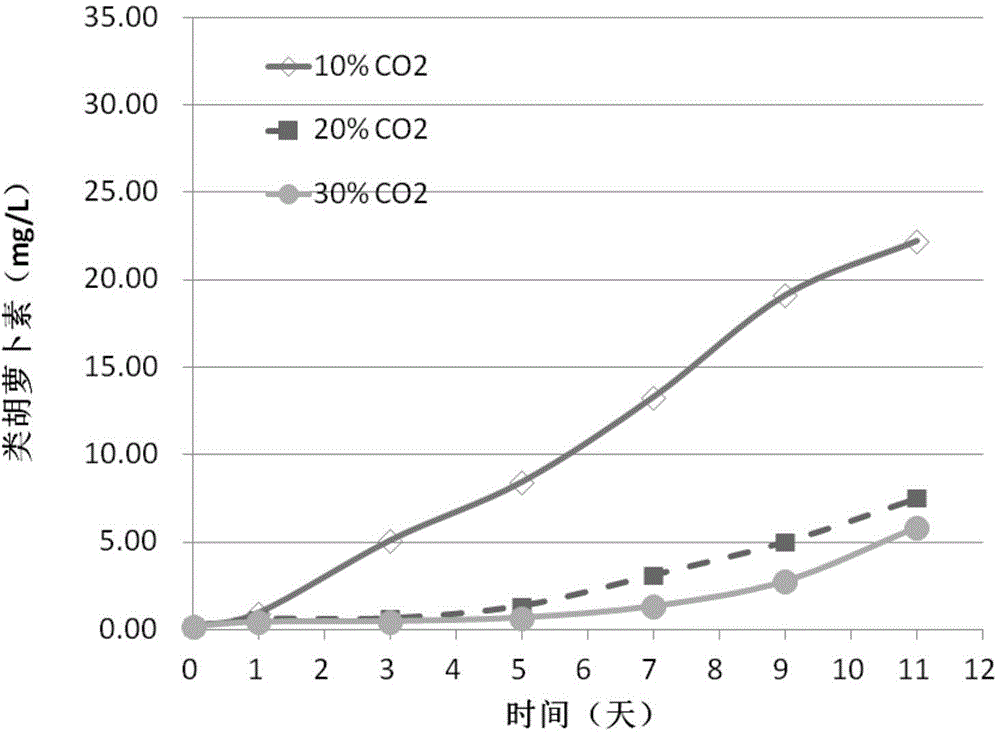

[0045] Alternatively, with 20% CO 2 The evolutionary strains obtained by adapting to evolution under the conditions of 10%, 20% and 30% CO 2 (volume ratio) condition and cultivated for 11 days, its carotenoid content all can reach more than 24mg / L (such as Figure 6 shown).

Embodiment 3

[0047] 1) After inoculating Chlamydomonas reinhardti in TAP medium with a cell density of 0.2g / L, culture it for 10 days under the following conditions as an adaptive evolution culture cycle;

[0048] Conditions: 40°C, 40% CO 2 and 500 μmol photonsm -2 the s -1 , The light-dark cycle is 16 hours / 8 hours, and the apparent ventilation rate is 1.0cm / s;

[0049] 2) Dilute the Chlamydomonas reinhardtii cultivated in step 1) to a cell density of 0.2 g / L, and perform a new cycle of cultivation for 10 days under the same conditions as in the above 1);

[0050] 3) Take step 1) as a culture cycle, enter the next culture cycle according to the method of step 2), repeat the above process for 50 culture cycles, so that the growth rate tends to be stable, so as to obtain CO tolerant 2 species of Chlamydomonas reinhardtii.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com