Plating device

A technology of plating solution and plating tank, applied in plating tank, cells, electrolytic components, etc., can solve the problems of unstable coating film quality and reduction of organic concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0031] Hereinafter, a preferred embodiment for carrying out the present invention will be described. However, the technical idea of the present invention is not limited to the following embodiments.

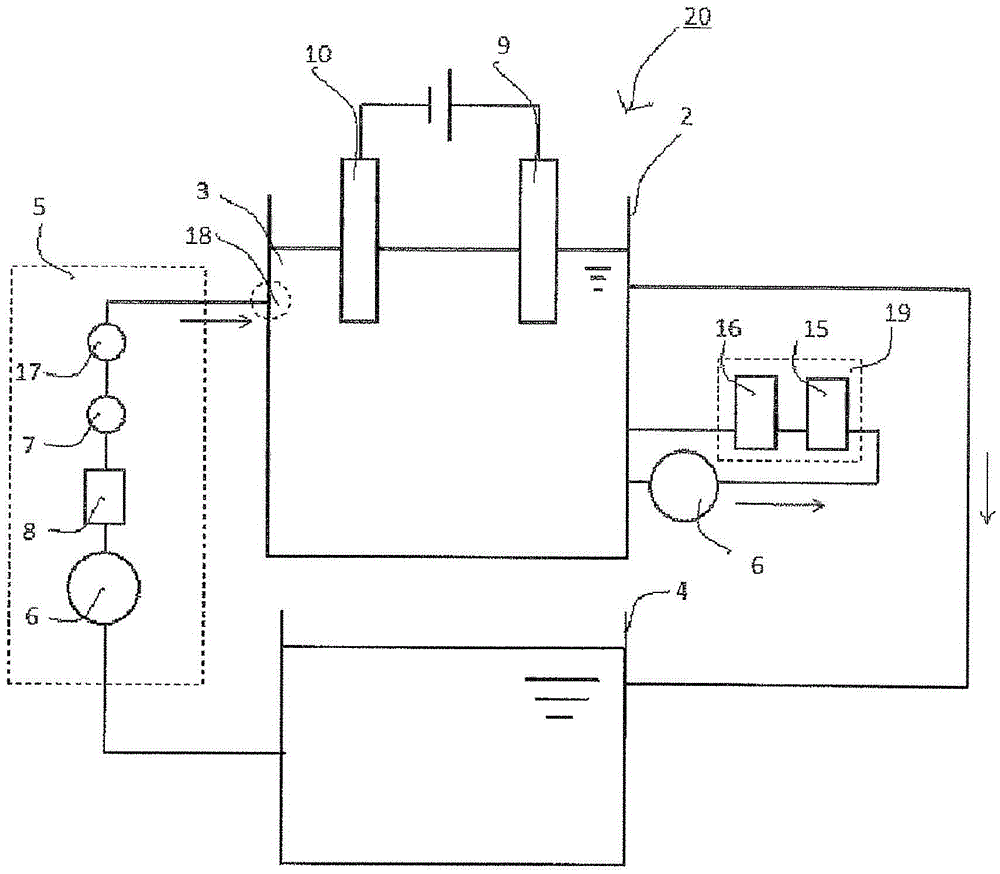

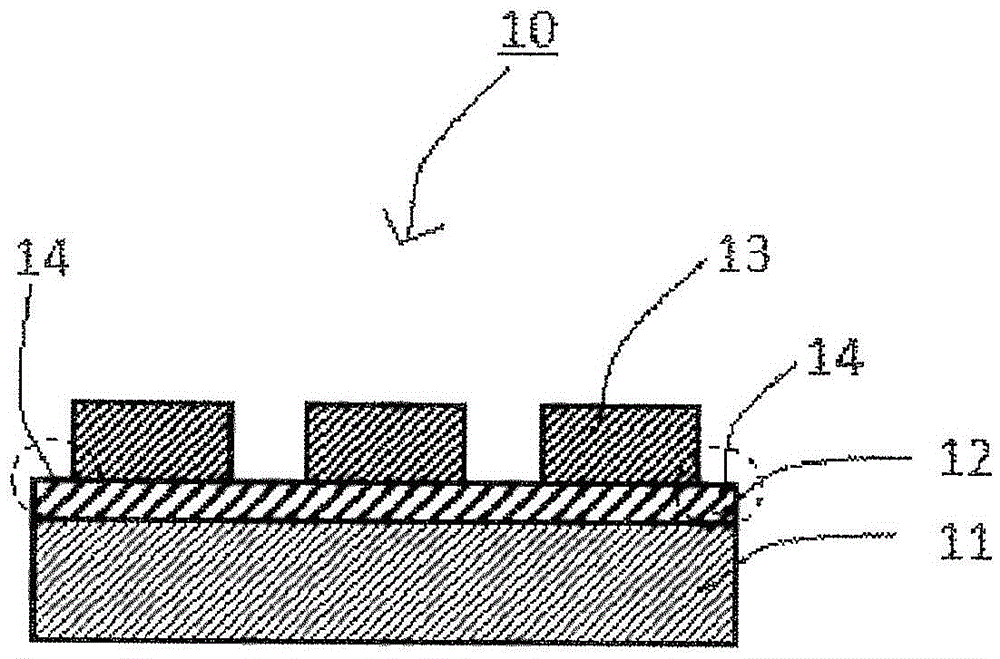

[0032] figure 1 A schematic diagram of the plating apparatus 20 of the first embodiment is shown in . The plating apparatus 20 of the present embodiment is equipped with: the plating tank 2 that is plated to the object 10 to be plated; The management tank 4 that stores the plating solution 3 overflowing from the plating tank 2; Plating solution conveying system 5 for circulating transport; anode electrode 9; impurity removal mechanism 19 connected with the plating layer to remove impurities from plating solution 3. The impurity removal mechanism 19 is divided into a carboxylic acid removal mechanism 15 and an alcohol removal mechanism 16 .

[0033] The plating solution 3 may contain conventionally known components used in electrolytic plating, and may contain metal ions of ...

no. 2 approach

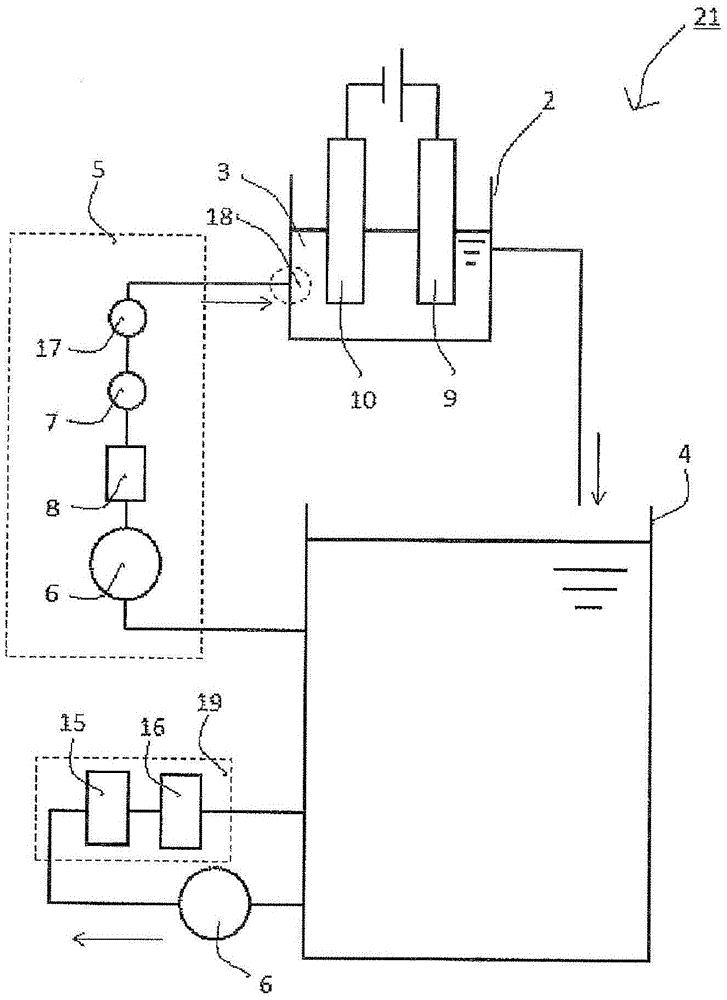

[0043] figure 2 It is a figure which shows the structure of the plating apparatus 21 in 2nd Embodiment. exist figure 2 Among them, the impurity removal mechanism 19 is connected to the management tank 4 . Other than that, it is the same as the plating apparatus 20 described in the first embodiment.

[0044] By connecting the impurity removal mechanism 19 to the management tank 4, the concentration change of the plating solution 3 in the plating tank 2 can be made more uniform. It has the effect of stabilizing the coating film thus obtained.

Embodiment

[0046] Hereinafter, the present invention will be further described with reference to examples and examples.

[0047] (Function confirmation of impurity removal mechanism)

[0048] The effect of the impurity removal mechanism in the copper sulfate plating solution will be described with reference to Examples 1 to 3. As a copper sulfate plating solution, 200 g / liter of copper sulfate pentahydrate, 100 g / liter of sulfuric acid, 50 mg / liter of hydrochloric acid, 100 mg / liter of polyethylene glycol (PEG) as an additive, bis(3-sulfopropyl) disulfide Prepare the plating solution with 8 mg / liter of SPS and 10 mg / liter of Yanlu Green B (JGB). A total of four substrates coated with a resist so as to have a thickness of 30 μm on a silicon wafer with a diameter of 6 inches were immersed in the above-mentioned copper sulfate plating solution, and left for 7 days to elute impurities to form a sample solution. It was confirmed that the carboxylic acid was acetic acid and the alcohol was 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com