Process for regenerating, recycling and treating waste strong brine produced in production of salted, preserved and pickled vegetables

A treatment process, a technology for concentrated brine, which is used in food industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Stable and reliable operation, solving the effect of difficult to meet emission standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

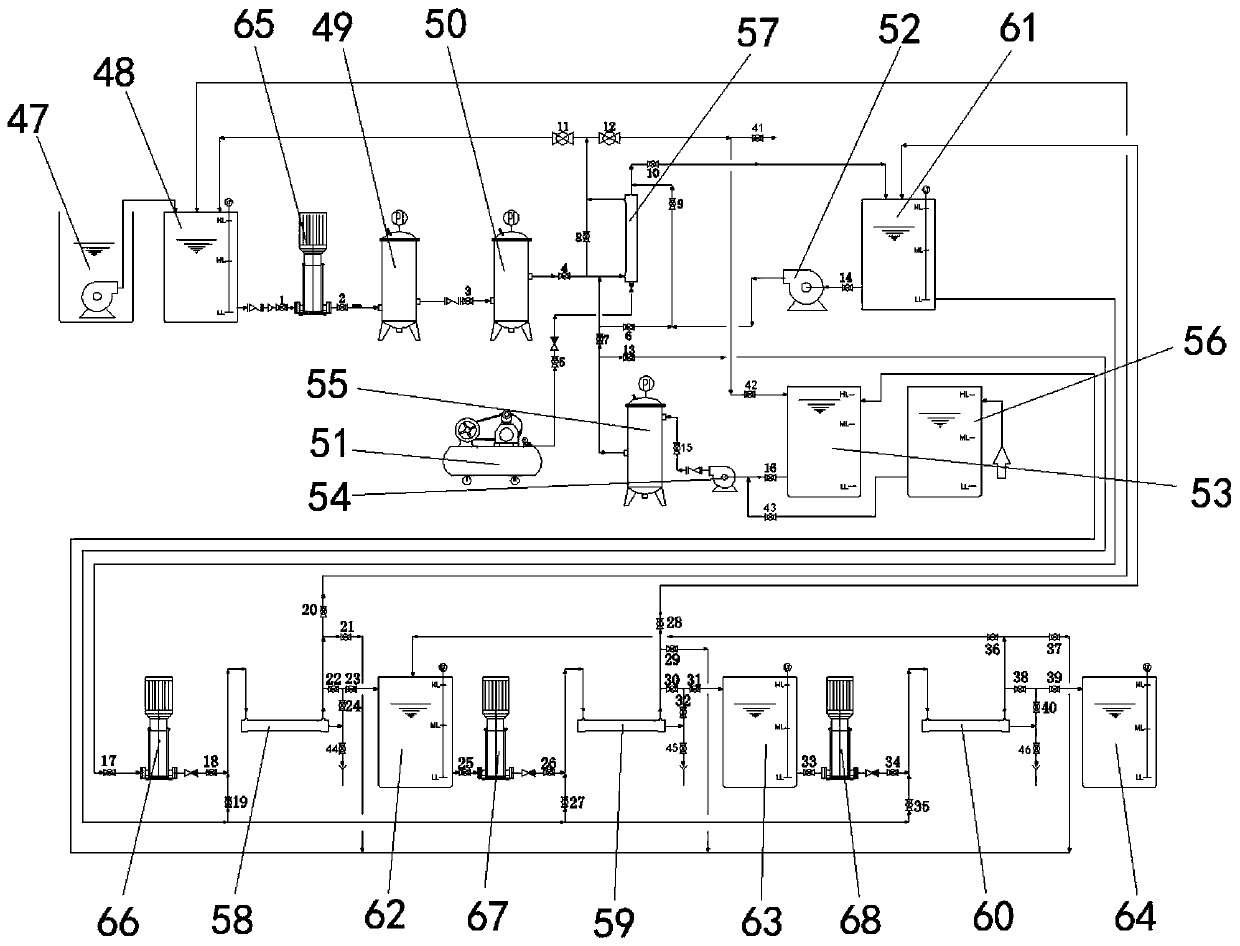

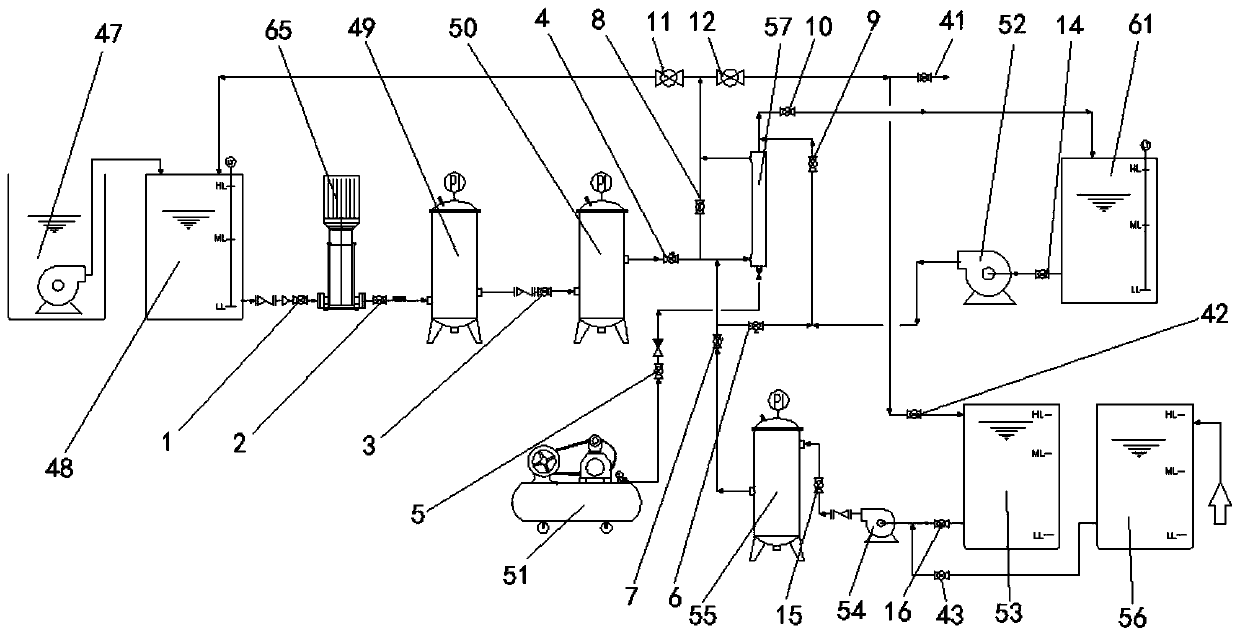

[0020] according to figure 1 , figure 2 , a treatment process for regeneration and reuse of pickled vegetables and kimchi waste concentrated brine, which mainly includes a primary regeneration system process flow. In-membrane backwashing process; in the filtering process, the liquid in the raw water tank 48 is pressurized by the primary booster pump 65 and enters the primary precision filter 50 through the primary bag filter 49; the output of the air compressor 51 The high-pressure air enters the primary filter membrane 57 together with the liquid discharged from the primary precision filter 50 for filtration, and the liquid filtered by the primary filter membrane 57 enters the primary brine storage tank 61 without being filtered by the primary filter membrane 57 The liquid impurities are then returned in the raw water tank 48; in the air scrubbing process alone, the air compressor 51 blows high-pressure air to the inlet side of the primary filter membrane 57, so that the li...

Embodiment 2

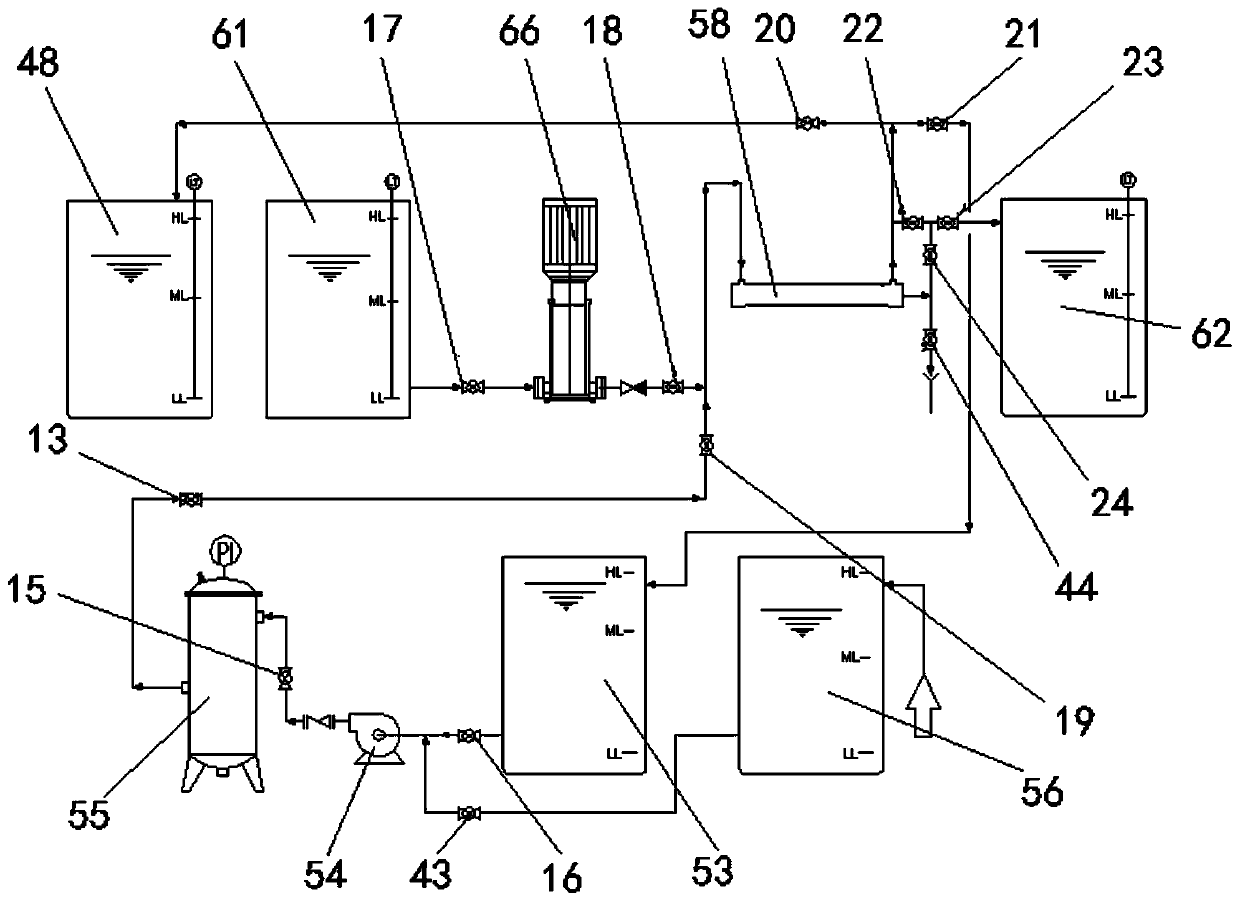

[0030] according to image 3 , also includes the process flow of the secondary regeneration system, the process flow of the secondary regeneration system is divided into a secondary filtering process, a secondary washing process, a secondary drug washing process and a secondary cleaning process; in the secondary filtering process, a The liquid in the secondary brine storage tank 61 enters the secondary filter membrane 58 after the pressurization of the secondary booster pump 66, and the liquid filtered by the secondary filter membrane 58 enters the secondary brine storage tank 62 without being filtered by the secondary filter membrane 58. The liquid filtered by the primary filter membrane 58 returns to the raw water tank 48; in the secondary flushing process, the liquid in the primary brine storage tank 61 returns after passing through the secondary filter membrane 58 after the pressurization of the secondary booster pump 66 In the former box; in the described secondary medici...

Embodiment 3

[0037] according to Figure 4 It also includes a process flow of a three-stage regeneration system, the process flow of the three-stage regeneration system is divided into a three-stage filtration process, a three-stage flushing process, a three-stage drug washing process and a three-stage cleaning process; in the three-stage filtration process, the two-stage The liquid in the brine storage tank 62 enters the three-stage filter membrane 59 after being pressurized by the three-stage booster pump 67, and the liquid filtered by the three-stage filter membrane 59 enters the three-stage brine storage tank 63 without being filtered by the three-stage filter membrane. The liquid filtered by the filter membrane 59 is returned to the first-stage brine storage tank 61; in the three-stage flushing process, the liquid in the second-stage brine storage tank 62 passes through the three-stage filter membrane 59 after the pressurization of the three-stage booster pump 67 Back in the former ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com