Totally closed loop cooler waste heat recovery device

A technology of waste heat recovery device and ring cooler, which is applied in waste heat treatment, lighting and heating equipment, treatment of discharged materials, etc., to achieve the effect of reducing heat consumption, reducing energy consumption and increasing energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

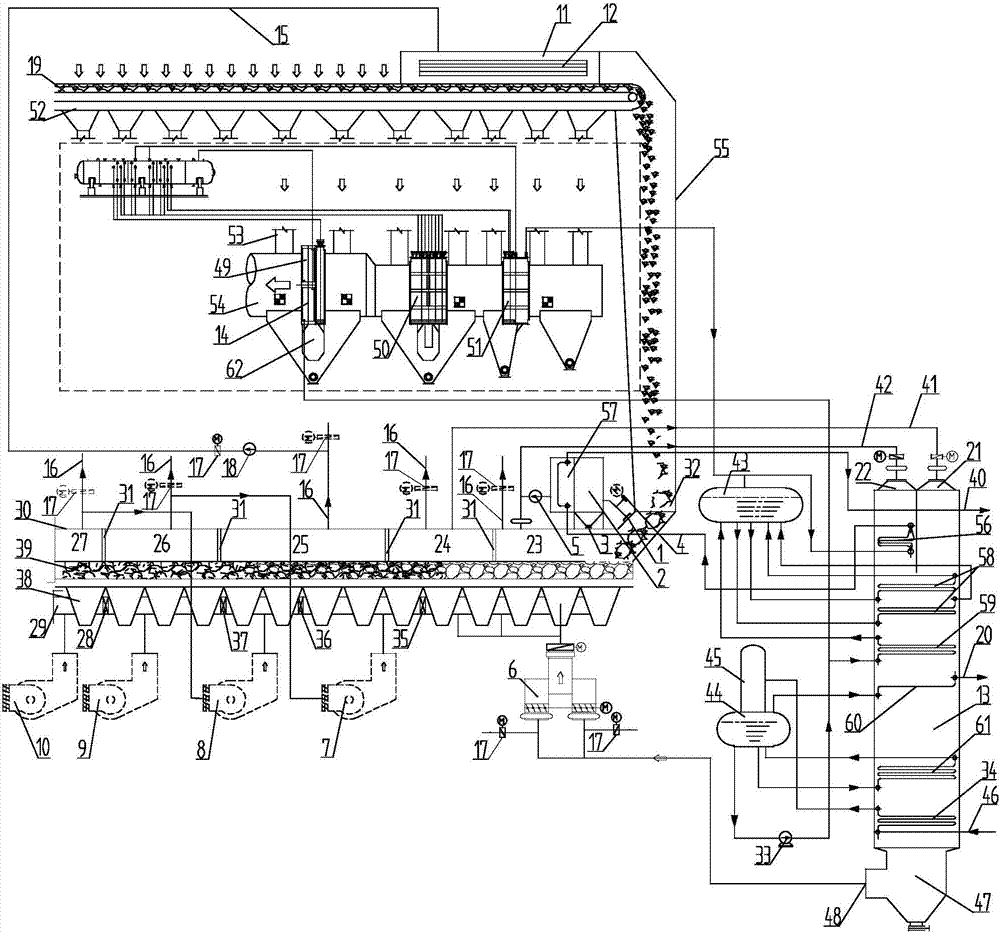

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] In this embodiment, the sintering machine 19 includes a sintering machine trolley, a transmission device, and sintered ore in the sintering machine trolley; the bottom of the sintering machine 19 is respectively provided with a bellows 52, a dust reduction pipe 53 and a sintering flue 54.

[0026] Such as figure 1 As shown, the receiving port 32 of the annular cooler 39 is directly welded to the first section 23 of the annular cooler, and the dust extraction point 1 at the receiving port 32 of the annular cooler 39 is connected to the dust collector 2 through the flue 15, and the flue 15 It is connected with the compensator of the dust collector 2 through a flange, and an air temperature regulating valve 4 is arranged on the inlet flue of the dust collector 2 . The bottom of the dust collector 2 is flange-connected to the cont...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap