Explosion-proof composite armor structure with elastic plate

A technology of elastic plate and armor, applied in the structure of armor plates, synthetic resin layered products, layered products, etc., can solve the problems of expensive, heavy cost, thick explosion-proof structure, etc., achieve light weight, improve explosion-proof ability, and explosion-proof The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

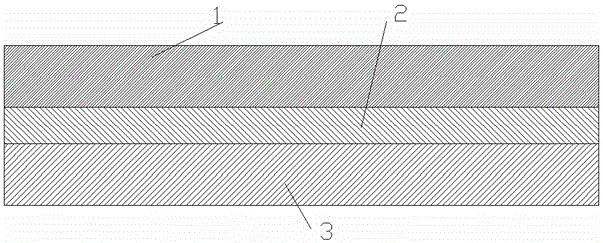

[0035] figure 2 A schematic structural diagram of Embodiment 1 of the present invention is shown. like figure 1 As shown, a new type of anti-explosion composite structure based on metamaterials includes metamaterial layer 1, bonding layer 2, and energy-absorbing buffer layer 3 from outside to inside. Wherein the metamaterial layer 1 is combined with the energy-absorbing buffer layer 3 through the bonding layer 2 . Wherein the metamaterial layer 1 is a microstructure composed of a metal-nonmetal sphere system. like Figure 5 As shown, the multiple microstructures are combined to form a metamaterial layer.

[0036] Preferably, the bonding layer 2 is water-soluble phenolic. The energy-absorbing buffer layer (3) includes Kevlar high-energy-absorbing material, ceramic brittle material, or a solid or hollow structure processed from honeycomb material or aluminum foam material. The physical parameters of Kevlar in the energy-absorbing buffer layer: the strength is 3.6GPa, the ...

Embodiment 2

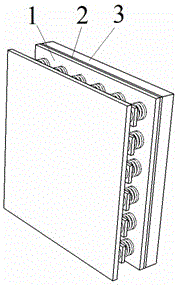

[0057] Embodiment 2 is a further improvement on the basis of Embodiment 1. like image 3 As shown, a new type of anti-explosion composite structure based on metamaterials includes metamaterial layer 1, bonding layer 2, and energy-absorbing buffer layer 3 from outside to inside. The components of the above-mentioned three-layer structure are the same as those in Embodiment 1, and will not be further described.

[0058] Embodiment 2 further arranges an elastic plate 7 outside the metamaterial layer 1, and a plurality of metal springs are arranged between the elastic plate 7 and the metamaterial layer 1, and the metal springs are a multi-row structure, and each row is a plurality of .

[0059] As a preference, the elastic plate 7 can be of the same composition as the metamaterial layer, i.e. also made of Figure 5 The microstructural composition shown.

[0060] Of course, the present invention has developed a new elastic board 7, the weight ratio of each component in the elas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Modulus of elongation | aaaaa | aaaaa |

| Bow to extremes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com