Testing platform for total-power wind-power converter with various specifications

A technology for wind power converters and test platforms, which is applied in the direction of measuring electrical variables, instruments, and measuring electricity. The effect of simplifying the process and reducing the construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

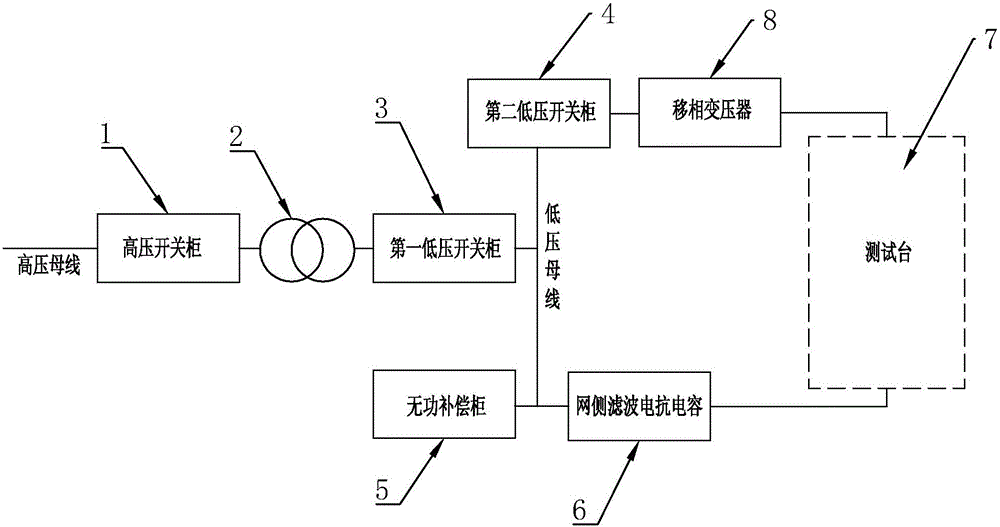

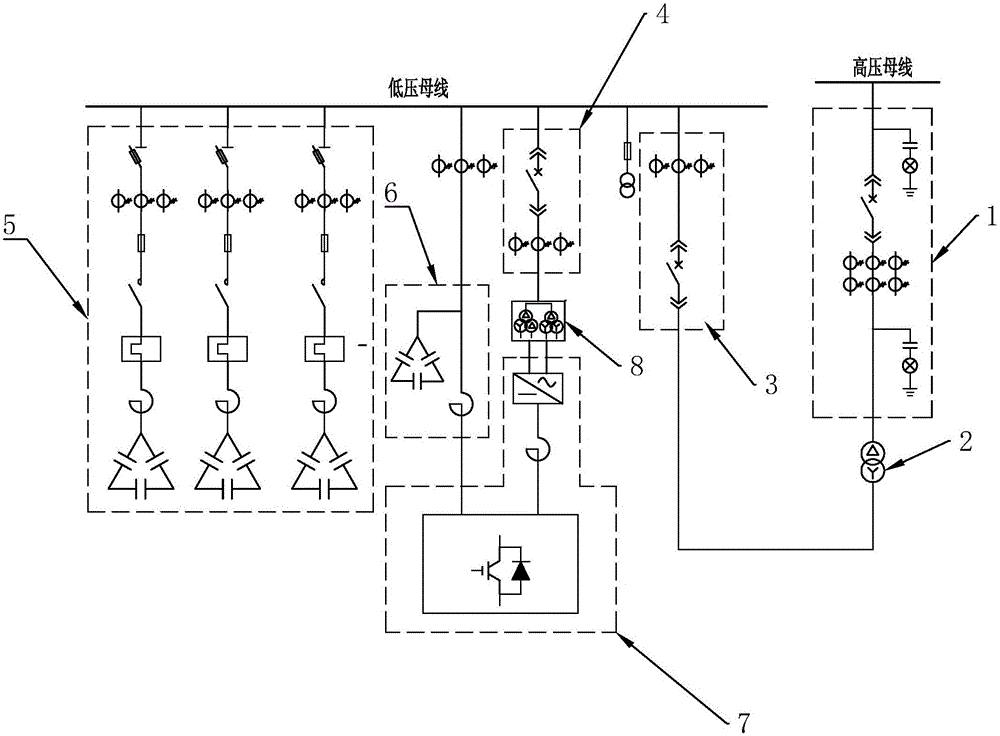

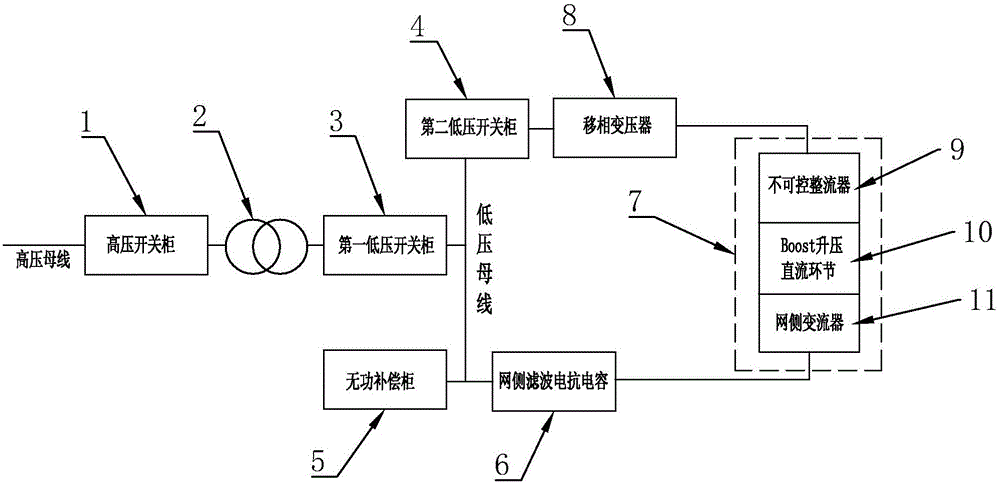

[0019] The present invention improves the full-power wind power converter test platform in the prior art, and replaces the motor-driven generator link with a phase-shifting generator to form a multi-standard full-power wind power converter test platform. The system consists of like figure 1 shown.

[0020] A multi-standard full-power wind power converter test platform provided by the present invention includes a high-voltage switchgear 1, a step-down transformer 2, a first switchgear 3, a second switchgear 4, a reactive power compensation cabinet 5, and a grid-side filter reactance capacitor 6. Test bench 7, phase-shifting transformer 8; one side of the high-voltage switchgear 1 is connected to the high-voltage bus, and the other side of the high-voltage switchgear 1 is connected to the primary side of the step-down transformer 2, and the step-down transformer The secondary side of 2 is connected to one side of the first low-voltage switchgear 3, the other side of the first l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com