Method for preparing Au-cluster/carbon nano tube composite catalyst

A composite catalyst and fuel cell technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems that have not yet been published in literature or patent reports, and achieve the effects of reduced preparation costs, high initial potential, and strong durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) According to the mass ratio of gold element and carbon element of 1:2, mix the chloroauric acid solution with a concentration of 2mg / mL and the aqueous dispersion of multi-walled carbon nanotubes with a concentration of 1mg / mL in sequence ; And this mixture is ultrasonic 2h, so that it is evenly mixed.

[0027] (2) At room temperature, stir magnetically at a speed of 500r / min for 0.5h, then raise the speed to 1000r / min, and mix 4mg of sodium borohydride (NaBH 4 ) into the mixed liquid rapidly, and continue magnetic stirring for 0.5h to obtain the Au / CNT composite material catalyst.

[0028] Catalytic performance test:

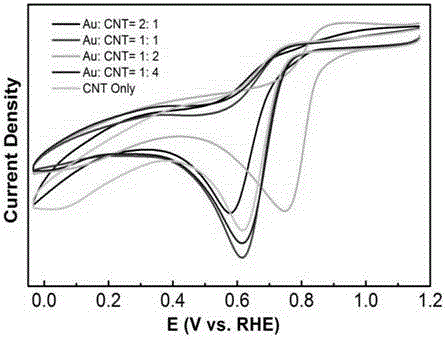

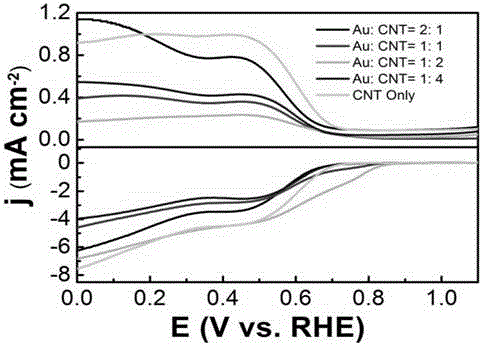

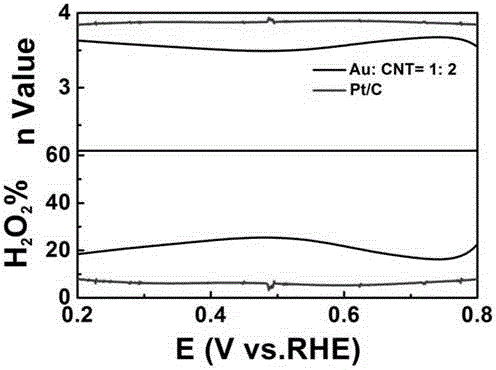

[0029] The electrochemical test and characterization was carried out in a test cell with a three-electrode system on a CHI750E electrochemical workstation produced by Shanghai Chenhua Company. Among them, the platinum wire is the counter electrode, the Ag / AgCl electrode is the reference electrode, and the glassy carbon electrode loaded with the cat...

Embodiment 2

[0035] (1) According to the mass ratio of gold element and carbon element of 1:4, the chloroauric acid solution with a concentration of 2mg / mL and the aqueous dispersion of multi-walled carbon nanotubes with a concentration of 1mg / mL were mixed in sequence ; And this mixture is ultrasonic 2h, so that it is evenly mixed.

[0036] (2) At room temperature, stir magnetically at a speed of 500r / min for 0.5h, then raise the speed to 1000r / min, and mix 4mg of sodium borohydride (NaBH 4 ) into the mixed liquid rapidly, and continue magnetic stirring for 0.5h to obtain the Au / CNT composite material catalyst.

Embodiment 3

[0038] (1) According to the mass ratio of gold element and carbon element of 1:1, mix the chloroauric acid solution with a concentration of 2mg / mL and the aqueous dispersion of multi-walled carbon nanotubes with a concentration of 1mg / mL in sequence ; And this mixture is ultrasonic 2h, so that it is evenly mixed.

[0039] (2) At room temperature, stir magnetically at a speed of 500r / min for 0.5h, then raise the speed to 1000r / min, and mix 4mg of sodium borohydride (NaBH 4 ) into the mixed liquid rapidly, and continue magnetic stirring for 0.5h to obtain the Au / CNT composite material catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com