Water-repellent composition, water-repellent fiber product, and method for producing water-repellent fiber product

A fiber product and composition technology, applied in the field of water repellent composition, can solve the problems of refractory and other problems, and achieve the effects of excellent water repellency, energy saving and load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

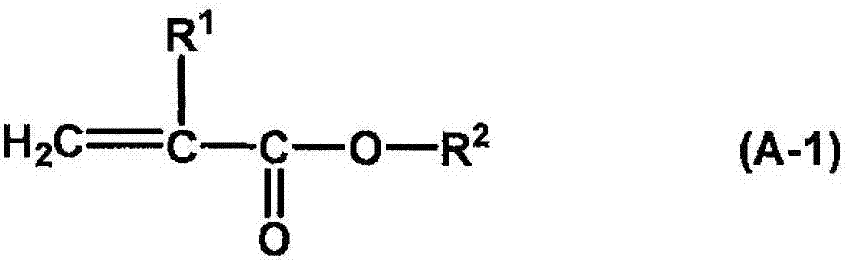

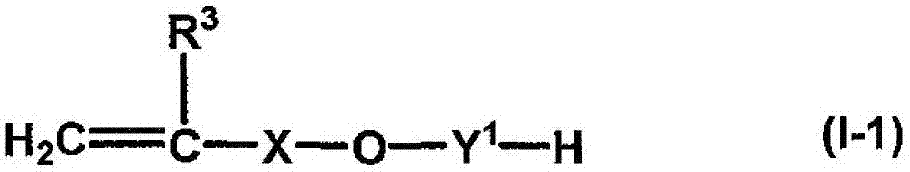

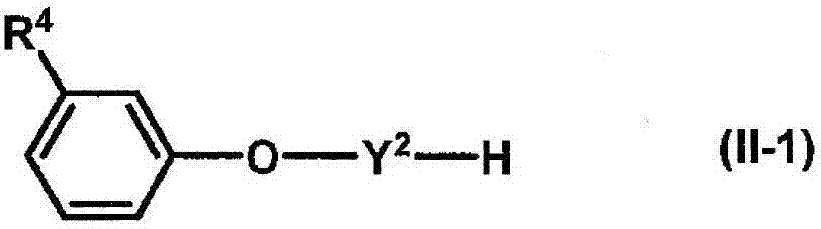

Method used

Image

Examples

Embodiment 1

[0169] 60 g of stearyl acrylate, LATEMUL PD-420 (manufactured by Kao Corporation, polyoxyalkylene alkenyl ether, HLB=12.6) 2 g, LATEMUL PD-430 (manufactured by Kao Corporation, polyoxyalkylene alkenyl ether) were added to a 500 mL flask. Ether, HLB=14.4) 2g, octadecyldimethylamine hydrochloride 3g, tripropylene glycol 20g, and water 162.75g were mixed and stirred at 45°C to obtain a liquid mixture. The mixture is irradiated with ultrasonic waves to emulsify and disperse all the monomers. Next, 0.25 g of azobis(isobutylamidine) dihydrochloride was added to the mixed liquid, and it was radically polymerized at 60° C. for 6 hours under a nitrogen atmosphere to obtain a non-fluorine-based compound with a polymer concentration of 26% by mass. polymer dispersion.

Embodiment 2

[0171] 55 g of stearyl acrylate, LATEMUL PD-420 (manufactured by Kao Corporation, polyoxyalkylene alkenyl ether, HLB=12.6) 2 g, LATEMUL PD-430 (manufactured by Kao Corporation, polyoxyalkylene alkenyl ether) were added to a 500 mL flask. Ether, HLB=14.4) 2g, 2-hydroxyethyl acrylate 5g, octadecyldimethylamine hydrochloride 3g, dodecyl mercaptan 0.15g, tripropylene glycol 20g and water 162.6g, and at 45 ℃ Mixing and stirring are performed to obtain a liquid mixture. The mixture is irradiated with ultrasonic waves to emulsify and disperse all the monomers. Next, 0.25 g of azobis(isobutylamidine) dihydrochloride was added to the mixed liquid, and it was radically polymerized at 60° C. for 6 hours under a nitrogen atmosphere to obtain a non-fluorine-based compound with a polymer concentration of 26% by mass. polymer dispersion.

Embodiment 3

[0173] 55 g of stearyl methacrylate, 2 g of LATEMUL PD-420 (manufactured by Kao Corporation, polyoxyalkylene alkenyl ether, HLB=12.6), LATEMUL PD-430 (manufactured by Kao Corporation, polyoxyalkylene group) were added to a 500 mL flask. Alkenyl ether, HLB=14.4) 2g, 2-hydroxyethyl acrylate 5g, octadecyldimethylamine hydrochloride 3g, dodecyl mercaptan 0.05g, tripropylene glycol 20g and water 162.7g, and in Mixing and stirring were performed at 45° C. to obtain a mixed liquid. The mixture is irradiated with ultrasonic waves to emulsify and disperse all the monomers. Next, 0.25 g of azobis(isobutylamidine) dihydrochloride was added to the mixed liquid, and it was radically polymerized at 60° C. for 6 hours under a nitrogen atmosphere to obtain a non-fluorine-based compound with a polymer concentration of 26% by mass. polymer dispersion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com