Preparation method of instant cured compound sorghum rice

A technology for compounding rice and sorghum, applied in food science, food ingredients as taste improvers, etc., can solve problems such as time-consuming and laborious, and achieve the effect of eliminating bitterness, better taste, and increasing nutritional and health care value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

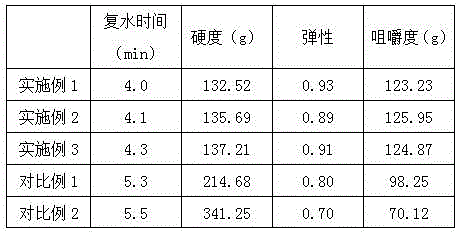

Examples

Embodiment 1

[0028] A preparation method of instant cooked sorghum compound rice. The raw materials are: 42 parts of whole sorghum powder, 17 parts of whole superfine potato powder, 48 parts of superfine mixed rice flour, 0.1 part of monoglyceride, 0.2 part of xanthan gum, 0.5 parts of sodium alginate;

[0029] Include the following steps:

[0030] (1)) Whole sorghum powder: Sorghum rice is cleaned, washed, and dried at 60°C for 24 hours, then crushed to 200 mesh, added with water until the water content of the powder is 16%, and then added carboxymethyl fiber accounting for 0.1% of the mass of sorghum powder Vegetables are prepared into balls with a diameter of 0.5-1cm, then put into tea seed oil and fry for 60 seconds, remove and cool, then fry for 20 seconds, remove, control the oil and cool, then pulverize to 400-500 mesh to obtain whole powder of sorghum;

[0031] (2) Potato powder: The potato powder is ultrafinely pulverized to 300-400 mesh to obtain superfine potato powder;

[003...

Embodiment 2

[0040] A method for preparing instant cooked sorghum compound rice. The raw materials are: 30 parts of sorghum whole powder, 20 parts of superfine potato whole powder, 30 parts of superfine mixed rice flour, 0.1 part of monoglyceride, 0.3 part of xanthan gum, 0.6 parts of sodium alginate.

[0041] Concrete steps are with embodiment 1.

Embodiment 3

[0043] A method for preparing instant cooked sorghum compound rice. The raw materials are: 50 parts of whole sorghum flour, 10 parts of whole superfine potato flour, 60 parts of superfine mixed rice flour, 0.3 part of monoglyceride, 0.1 part of xanthan gum, 0.4 parts of sodium alginate.

[0044] Concrete steps are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com