Manufacturing method of individual hip joint percutaneous puncture guide plate

A production method and hip joint technology, applied in the field of medical devices, can solve the problems of low puncture success rate, increased radiation dose, and easy nerve damage, etc., and achieve the effects of reduced operation time, fast response, and low cost of personalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

[0025] A method for making a personalized hip joint percutaneous puncture guide, comprising the steps of:

[0026] 1) Establishment of 3D geometric model: Obtain thin-layer scan data of the patient's hip joint, import it into medical modeling software in DICOM format, and generate visualized 3D models of bones, soft tissues, skin, and important blood vessels through morphological processing, and store them in stl Format export and save;

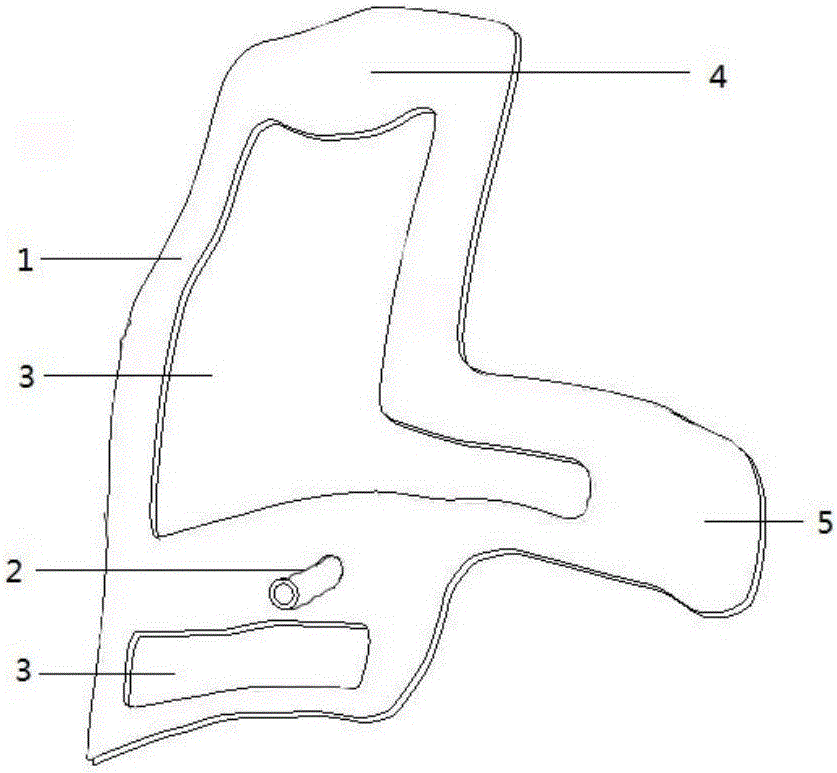

[0027] 2) Determine the puncture channel 2 (such as figure 1 shown): In the medical modeling software, determine the puncture target point, needle insertion direction and angle, extract the shape of the puncture needle, and fit it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com