Reinforced hollow fiber composite membrane and preparation method thereof

A fiber composite and reinforced technology, which is applied in the field of separation membrane composite material preparation, can solve the problems of reducing the strength of hollow fiber membrane filaments, difficulty in ensuring uniformity, and high feasibility of polyamide desalination layer, achieving high tensile strength and strengthening mechanical properties. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

[0038] Concrete technical scheme of the present invention is as follows:

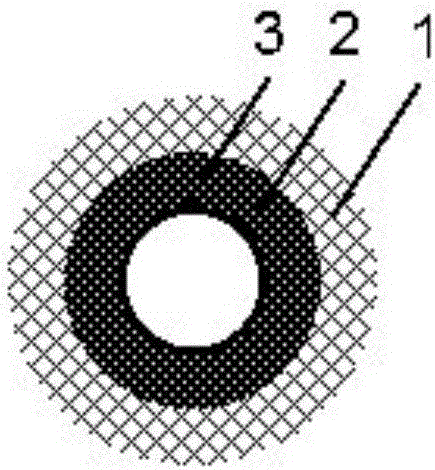

[0039] Such as figure 1 As shown, a reinforced hollow fiber composite membrane includes an outer network structure 1, a middle porous transition layer 2, and an inner polyamide desalination layer 3; the thickness of the outer network structure 1 is 50-500 μm; the The porosity of the middle porous transition layer 2 is 50-85%, the thickness is 50-300 μm, and the inner surface pore diameter is 5-50 nm; the pure water flux of the inner polyamide desalination layer 3 is 10-100 L / (m 2 ·h·MPa), the diffusion rate of sodium chloride is 0.05-5L / (m 2 h); the tensile force of the reinf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com