Oil pressure assistance braking system and control method thereof

A technology of a braking system and a control method, which is applied to the control of the above-mentioned braking system and the field of hydraulic power-assisted braking system, can solve problems such as power consumption and noise, and achieve fast adjustment response, compact system structure and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

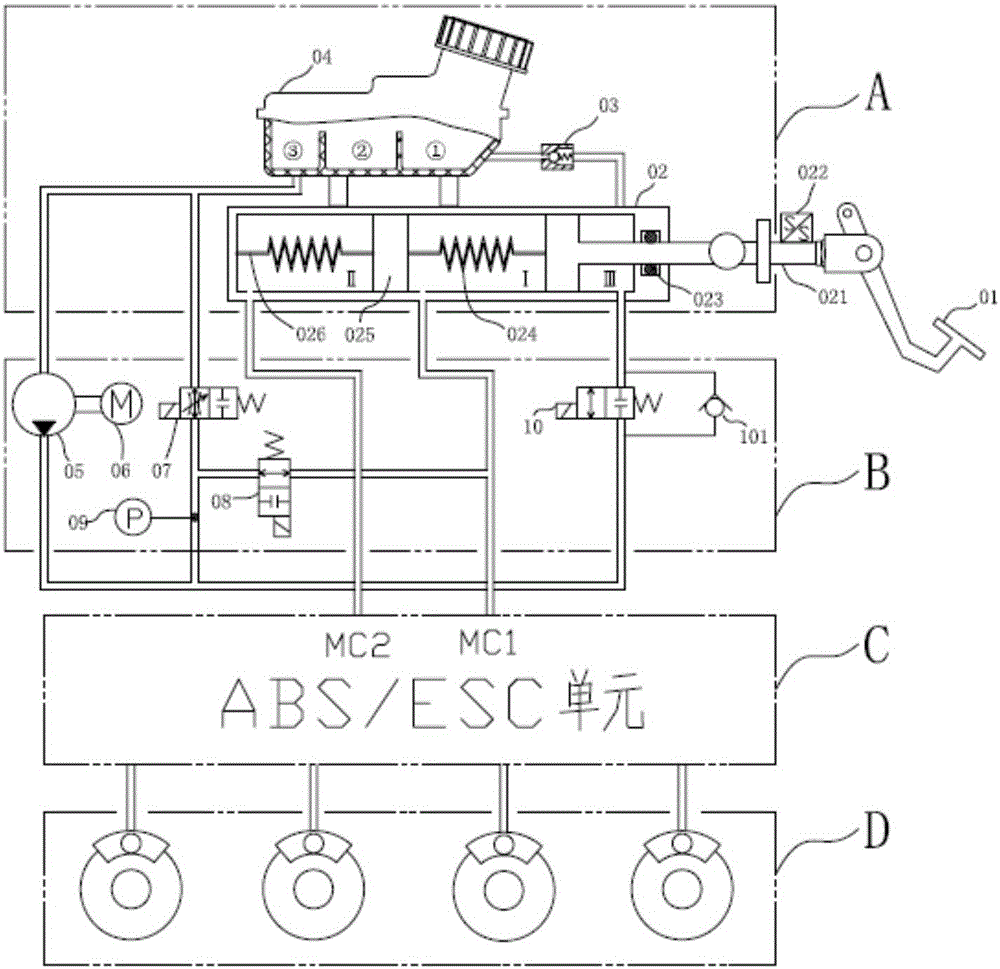

specific Embodiment approach

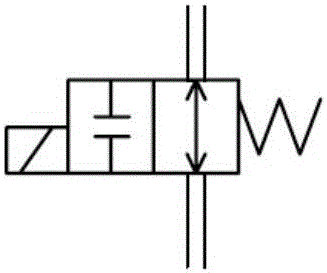

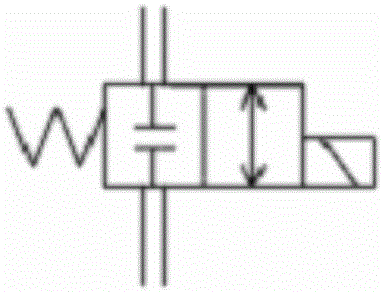

[0125] The pressure sensor 09 transmits the signal to the electronic control unit, and the electronic control unit controls the normally open solenoid valve 08 to be energized and closed, which cuts off the connection between the boost source and the leakage chamber, and drives the hydraulic pump 05 and the motor 06 to work at the same time, and the brake hydraulic pressure is normally closed. The solenoid valve 10 flows into the chamber III of the brake master cylinder 02, and pushes the pedal piston rod 021 to move forward to realize power boosting.

[0126] 7. Figure 15 It is a schematic diagram of the relationship curve between the brake hydraulic pressure P and the pedal stroke S of the hydraulic power assist system of the present invention.

[0127] In the present invention, the electronic control unit drives the hydraulic pump 05 and the motor 06 to pressurize the system, and at the same time controls the valve opening of the pressure regulating valve 07 to adjust the ...

Embodiment approach

[0128] 8. The stepped structure of the piston rod of the piston in the master cylinder makes the hydraulic booster system of the present invention not need to add a pedal simulation device, and can also achieve a good pedal feeling. The specific implementation method is:

[0129] The pressure difference formed by the pedal piston rod 021 in the piston bore area ratio of the first chamber and the third chamber of the brake master cylinder 02 is used as the driver's pedal feeling. According to the needs of customers, an appropriate piston-to-bore ratio can be designed to achieve the required boost ratio.

[0130] Five, the expansion technical scheme of the present invention:

[0131] The above-mentioned content has expressed the working principle and the hydraulic circuit of the present invention's scheme completely, and the present invention has done following expansion on the basis of this scheme:

[0132] Such as Figure 16 As shown, a high-pressure accumulator 11 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com