Method for preparing unsaturated carboxylate solution modified concrete compound material

A composite material and carboxylate technology, which is applied in the field of building materials, can solve the problems of increased cost and reduced durability of concrete, and achieve the effects of reduced blocking, short construction time, and short coagulation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] For the repair of existing highway bridges with rapid construction as the main purpose, in order to shorten the traffic closure time, reduce the impact on vehicle traffic, and meet the requirements of expansion joints, cold processing can be used in the actual construction process, as shown in Table 1. The weight ratios shown.

[0029] Table 1

[0030] Element

Weight ratio

100 copies

water

30 copies

30 copies

10 copies

30%~40% magnesium acrylate solution

100 copies

0.1 part

10 copies

Silica

10 copies

Polypropylene fibers

10 copies

aggregate

350 copies

[0031] The preparation process is:

[0032] After mixing and stirring water and magnesium acrylate solution for 2 minutes, add sodium persulfate and polypropylene fiber in turn and stir until uniformly dispersed to form mixed so...

Embodiment 2

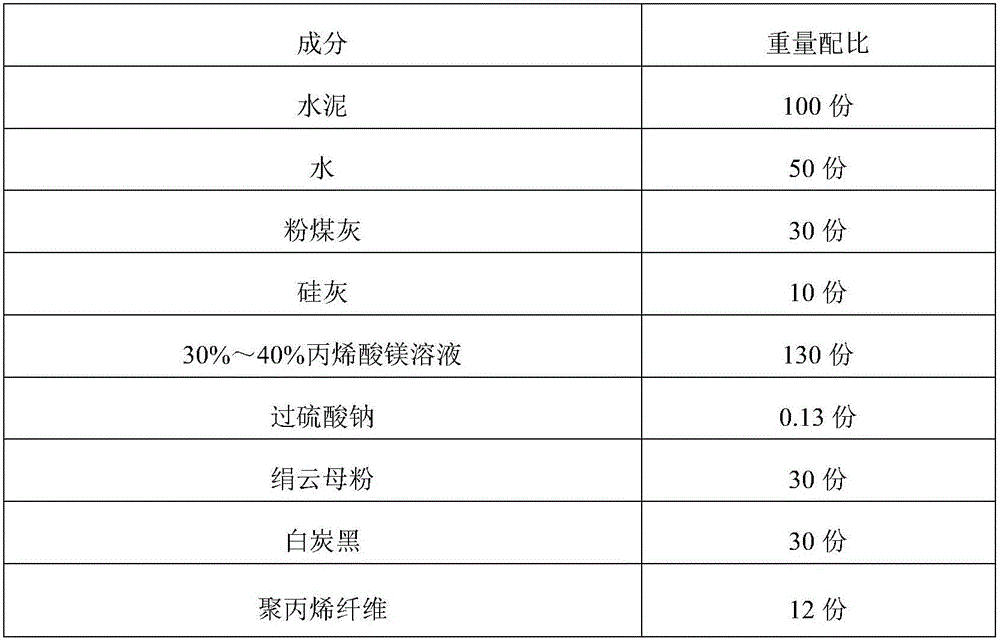

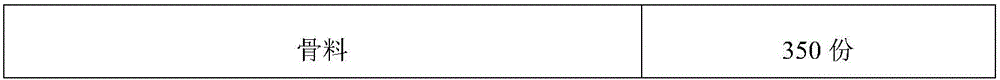

[0035] The main purpose is to meet the durability and elastic-plastic requirements for the construction of new road bridge expansion joints. In order to meet the durability requirements of engineering structure expansion joints and the purpose of driving comfort, cold processing is used in the actual construction process, as shown in Table 2. The weight ratio shown.

[0036] Table 2

[0037]

[0038]

[0039] The preparation process is:

[0040] After mixing and stirring water and magnesium acrylate solution for 2 minutes, add sodium persulfate and polypropylene fiber in turn and stir until uniformly dispersed to form mixed solution A; aggregate, cement, fly ash, silica fume, sericite powder and white carbon Mix black and stir until evenly dispersed, add 1 / 2 of mixed solution A and stir for 2 minutes, then add the remaining 1 / 2 of mixed solution A, stir until evenly dispersed.

[0041] The strength of the elastic-plastic material obtained in this example increases rapidl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com