Method for preparing biodegradable material poly-beta-hydroxybutyrate

A biodegradable material, a technology of hydroxybutyrate, which is applied in the field of preparing biodegradable material poly-β-hydroxybutyrate, can solve problems such as being inconsistent with environmental protection, shorten reaction time, reduce production cost, and simplify preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

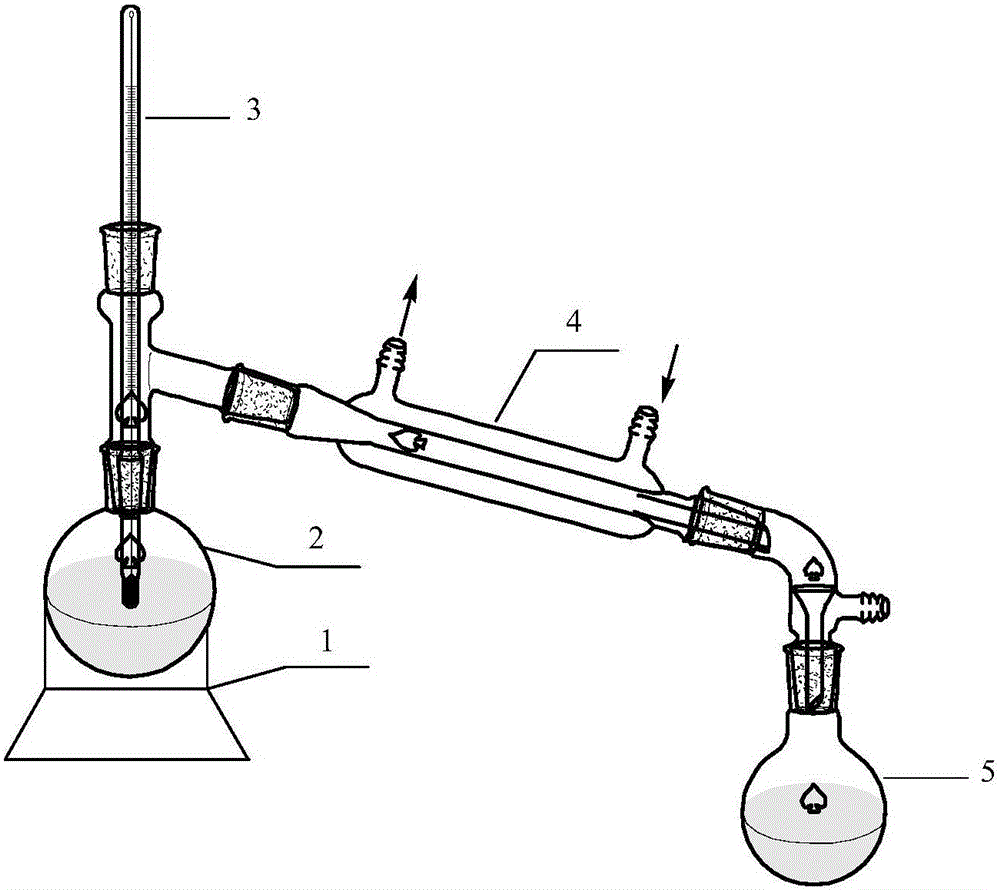

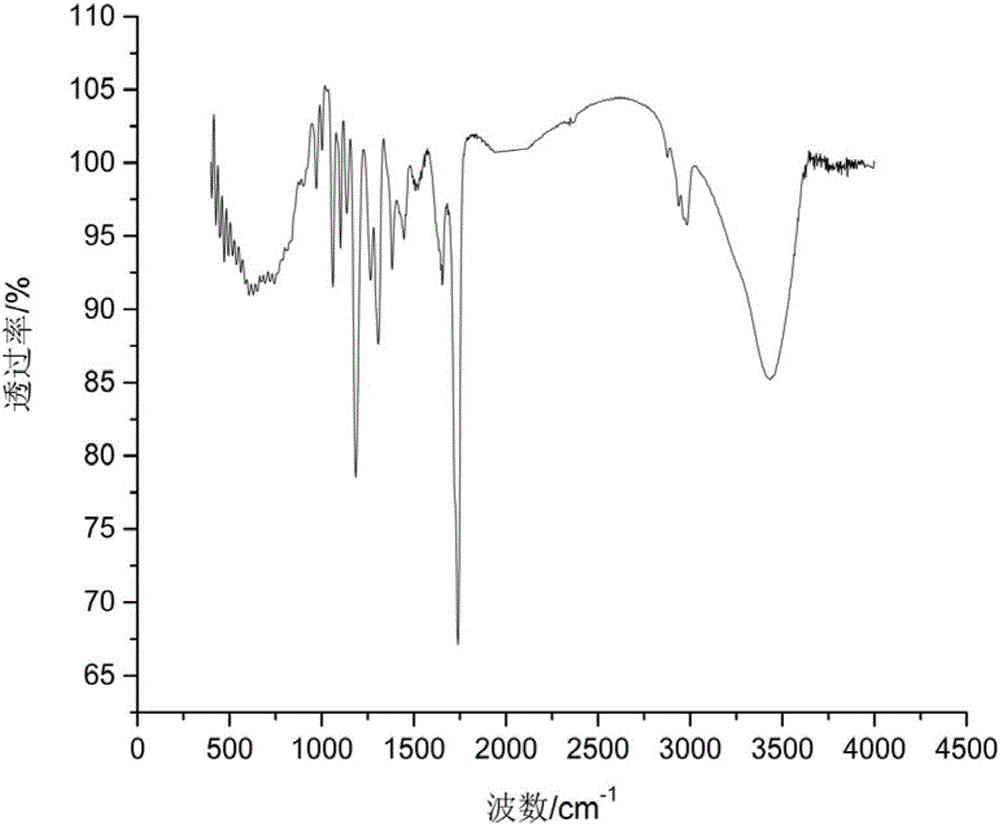

Embodiment 1

[0024] 30 mL of ethyl 3-hydroxybutyrate was placed in a 250 mL round bottom flask, 10 mL of tetrabutyl titanate with a mass concentration of 98% was added, and 0.11 mL of deionized water was added dropwise. The flask was heated by an electric heating mantle, and reacted at about 160°C for 2.5 hours to obtain the product poly-β-hydroxybutyrate. After testing, the sample size of the prepared product was 4.0257g, and the viscosity-average molecular weight of the product was 55455.5g / mol.

Embodiment 2

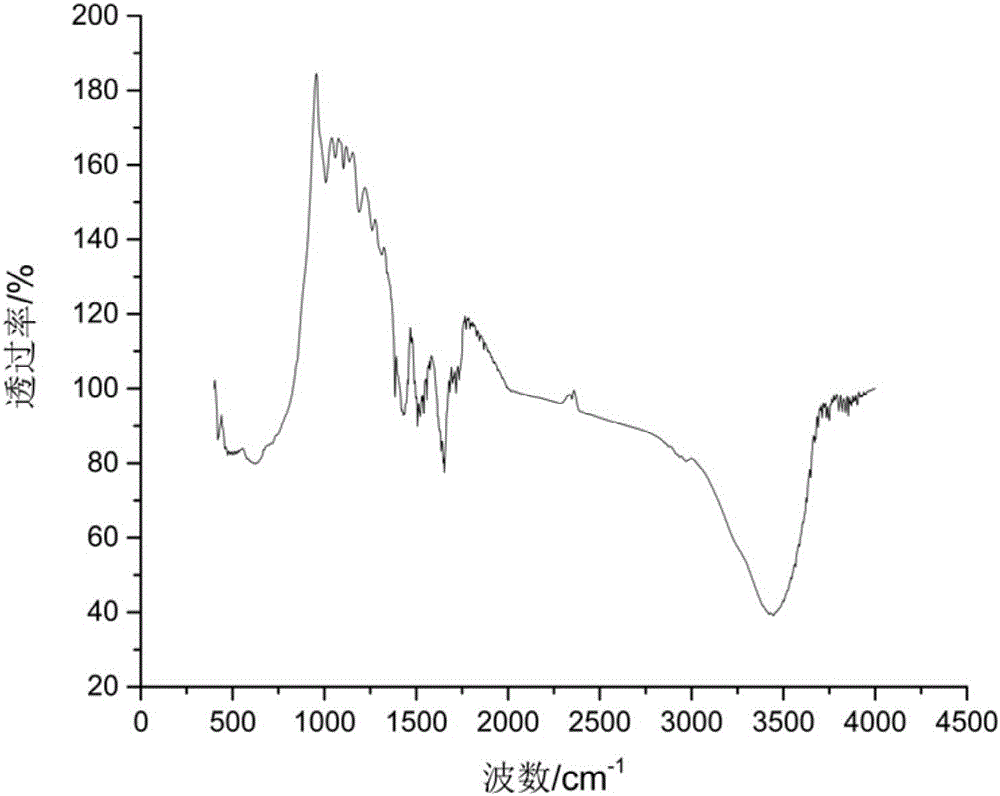

[0026] 30 mL of ethyl 3-hydroxybutyrate was placed in a 250 mL round bottom flask, 10 mL of tetrabutyl titanate with a mass concentration of 98% was added, and 0.25 mL of deionized water was added dropwise. The flask was heated by an electric heating mantle, and reacted at about 150°C for 2.5 hours to obtain the product poly-β-hydroxybutyrate. After testing, the sample size of the prepared product was 6.7267g, and the viscosity-average molecular weight of the product was 30506.4g / mol.

Embodiment 3

[0028] 45 mL of ethyl 3-hydroxybutyrate was placed in a 250 mL round bottom flask, 15 mL of tetrabutyl titanate with a mass concentration of 98% was added, and 0.11 mL of deionized water was added dropwise. Place the flask in an electric heating mantle to heat, and react at about 155°C for 3.5 hours to obtain the product poly-β-hydroxybutyrate. After testing, the sample size of the prepared product was 3.0805g, and the viscosity-average molecular weight of the product was 25449.3g / mol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com