Preparation method and corrosion-preventing implementation method of super-hydrophobic sponge material

A technology of superhydrophobic sponge and implementation method is applied in the fields of preparation of superhydrophobic sponge material and long-term metal anticorrosion, which can solve problems such as loss of superhydrophobicity, and achieves convenient large-scale industrial production, low cost, and simple design structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment one (best embodiment)

[0041] 1. Preparation of superhydrophobic sponge material:

[0042] 1) Soak a 2cm×2cm×2.5cm melamine sponge in acetone and absolute ethanol in sequence for ultrasonic cleaning to remove sponge impurities, take it out and air dry it for 4 hours, and set aside;

[0043]2) Soak the melamine sponge treated in step 1) in the hydrophobic modifier solution, control the soaking time for 24h, make the hydrophobic modifier adhere to the surface of the melamine sponge, and the solvent in the hydrophobic modifier solution is n-hexane alkane, the hydrophobic modifier is dodecyl trichlorosilane, and the hydrophobic modifier solution is mixed with n-hexane and dodecyl trichlorosilane with a volume ratio of 1:9;

[0044] 3) After taking out the melamine sponge treated in step 2), air-dry it naturally for 8 hours to obtain a superhydrophobic sponge material.

[0045] 2. Performance test of superhydrophobic sponge material

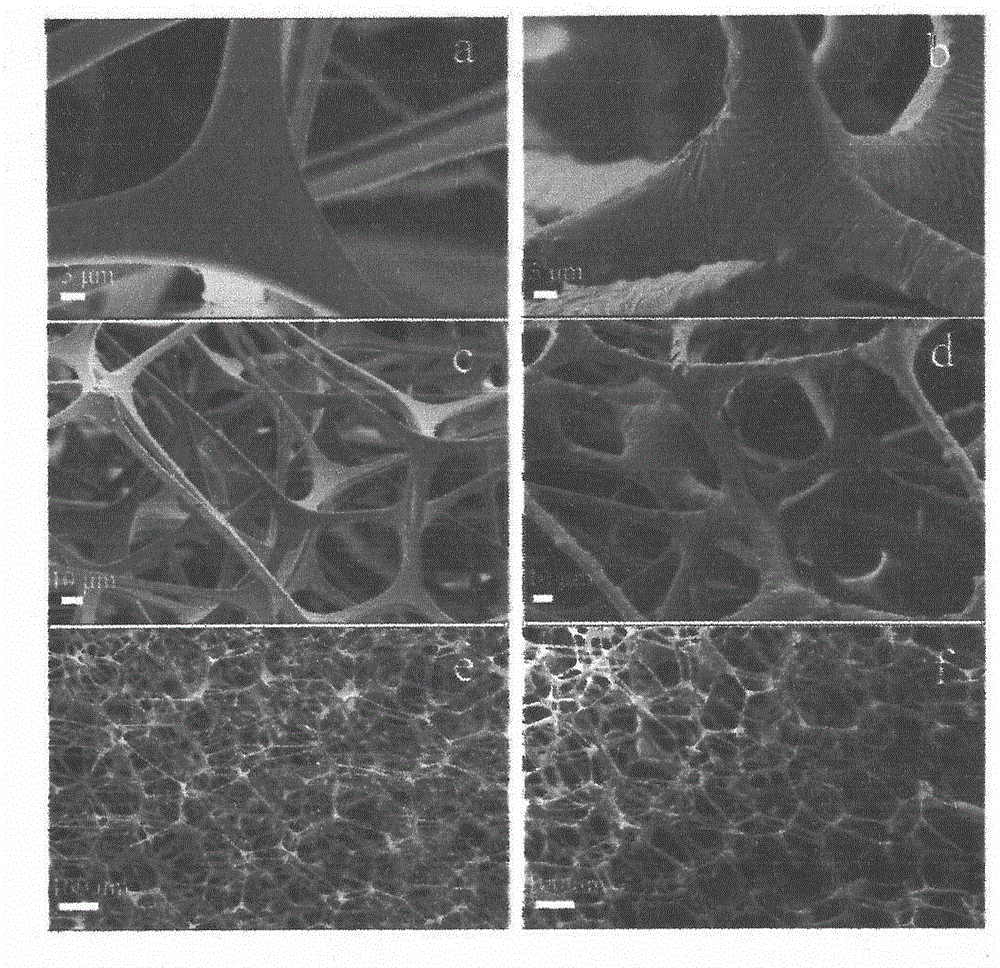

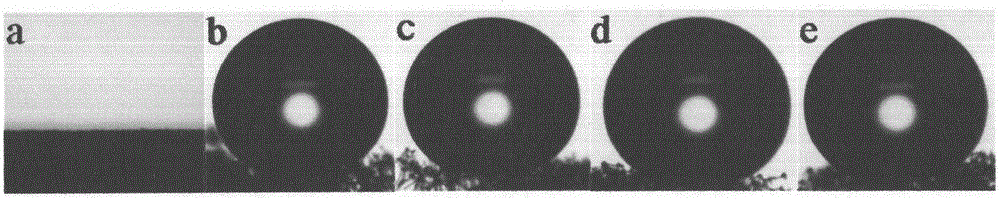

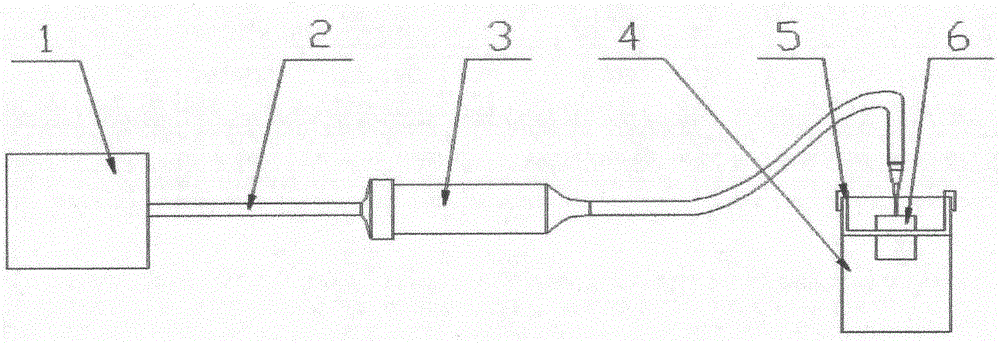

[0046] SEM morphology obs...

Embodiment 2

[0065] 1) Soak a 2cm×2cm×2.5cm melamine sponge in acetone and absolute ethanol in sequence for ultrasonic cleaning to remove sponge impurities, take it out and air dry it for 4 hours, and set aside;

[0066] 2) Soak the melamine sponge treated in step 1) in the hydrophobic modifier solution, control the soaking time to 30h, make the hydrophobic modifier adhere to the surface of the melamine sponge, and the solvent in the hydrophobic modifier solution is ethanol , the hydrophobic modifier is n-octyltrichlorosilane, and the hydrophobic modifier solution is formed by mixing ethanol and n-octyltrichlorosilane with a volume ratio of 1:5;

[0067] 3) After taking out the melamine sponge treated in step 2), air-dry it naturally for 6 hours to obtain a superhydrophobic sponge material.

Embodiment 3

[0069] 1) Soak a 2cm×2cm×2.5cm melamine sponge in acetone and absolute ethanol in sequence for ultrasonic cleaning to remove sponge impurities, take it out and air dry it for 4 hours, and set aside;

[0070] 2) Soak the melamine sponge treated in step 1) in the hydrophobic modifier solution, control the soaking time for 10h, make the hydrophobic modifier adhere to the surface of the melamine sponge, and the solvent in the hydrophobic modifier solution is three Chloromethane, the hydrophobic modifier is n-decyltrichlorosilane, and the hydrophobic modifier solution is mixed with chloroform and n-decyltrichlorosilane at a volume ratio of 1:100;

[0071] 3) After taking out the melamine sponge treated in step 2), air-dry it naturally for 12 hours to obtain a superhydrophobic sponge material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com