An automatic sanding and thickening system for diamond grinding wheel and its application method

A diamond and grinding wheel technology, used in grinding devices, metal processing equipment, grinding/polishing equipment, etc., can solve the problems that the uniformity of sanding is difficult to ensure, and the appearance and consistency of the finished grinding wheel are affected, and the structure is simple and the appearance is simple. Consistent, human-resource-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

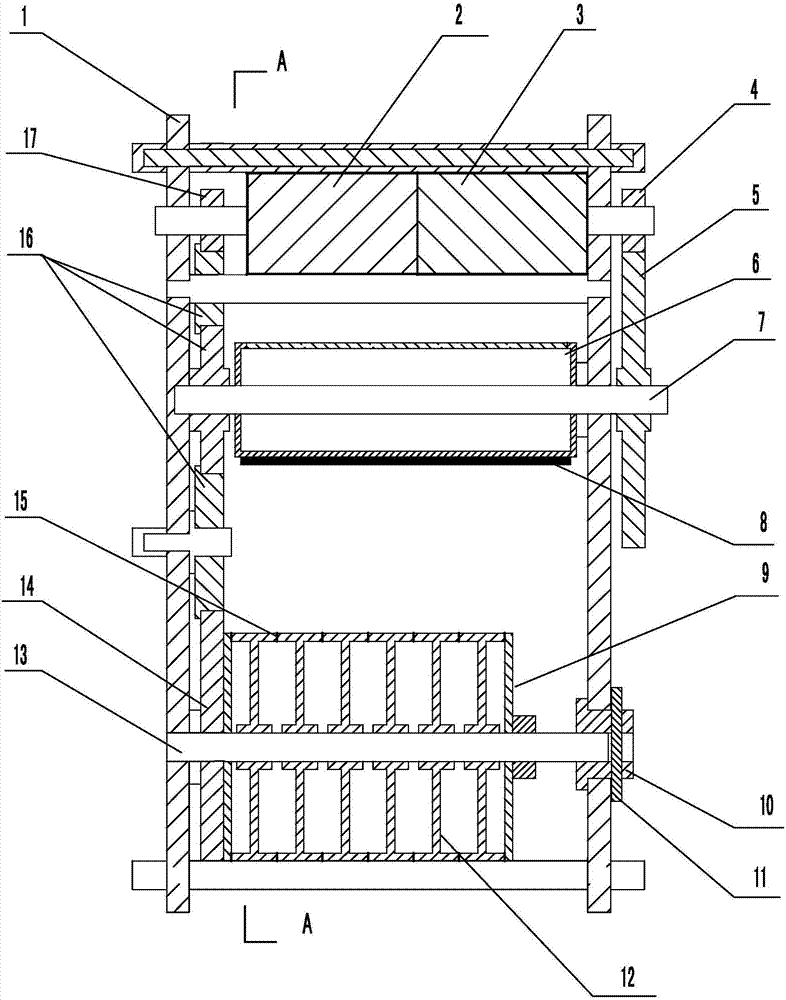

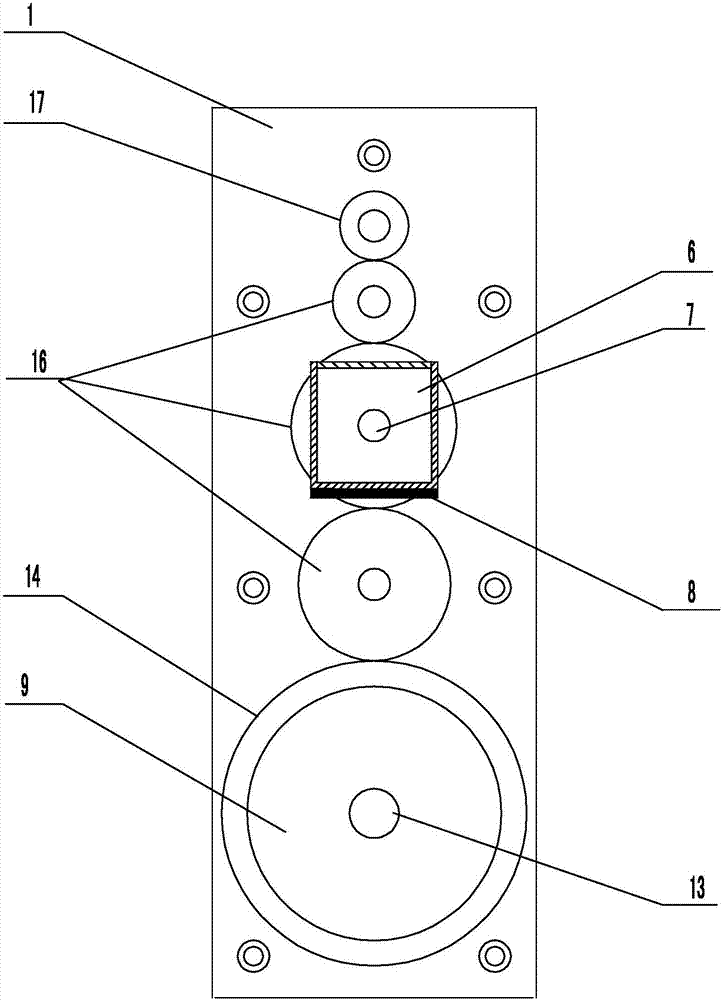

[0044] Embodiment of automatic sanding and thickening system for diamond grinding wheel

[0045] Example of the automatic sanding and thickening system for diamond grinding wheels figure 1 and 2 As shown, it includes electroplating device, grinding wheel rotating device, sanding device and central controller. The electroplating device includes a time-controlled arbitrary waveform steady-current power supply, a grinding tire body assembly mechanism and an anode plate 8 . The grinding wheel rotation device includes a B motor 2 and a transmission mechanism that drive the grinding tire body to rotate. The sand loading device includes an A motor 3 and a diamond box 6 that drive the diamond box 6 to rotate. The central controller is connected to control the time-controlled arbitrary waveform steady-current power supply, B motor 2 and A motor 3. figure 1 The central controller and time-controlled arbitrary waveform constant current power supply are not shown in the figure.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com