Method for backfilling of tunnel construction through TBM method and equipment for method

A technology for tunnels and tunnels, which is applied in the field of backfilling methods and equipment for TBM tunnel or tunnel construction, which can solve problems such as large coefficient of variation, damaged cement slurry mix ratio, bad geology, etc., and achieve strong segregation resistance and strong stop Water blocking ability, the effect of resisting water erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be described in detail below in combination with specific embodiments.

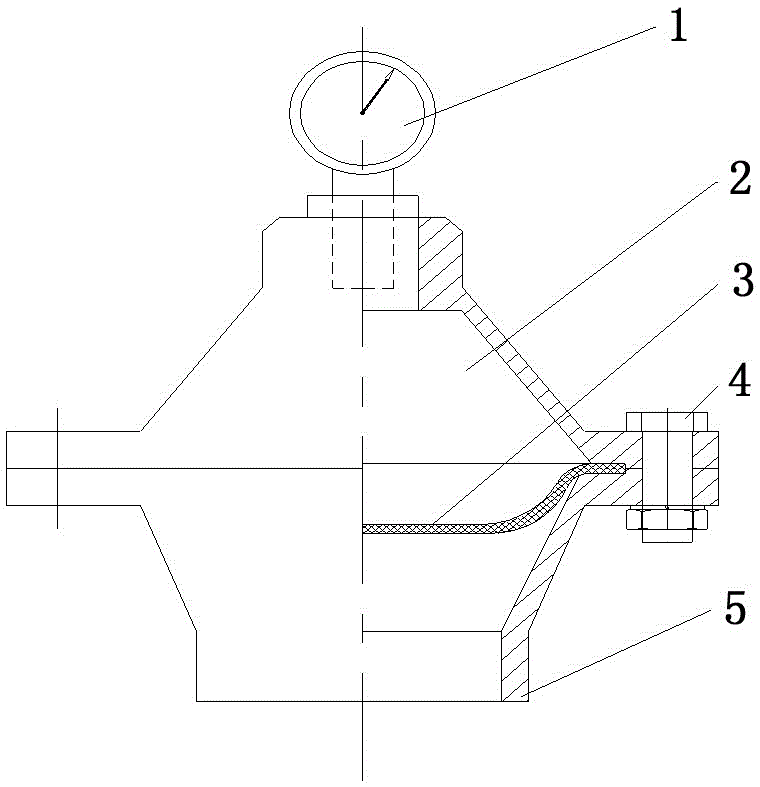

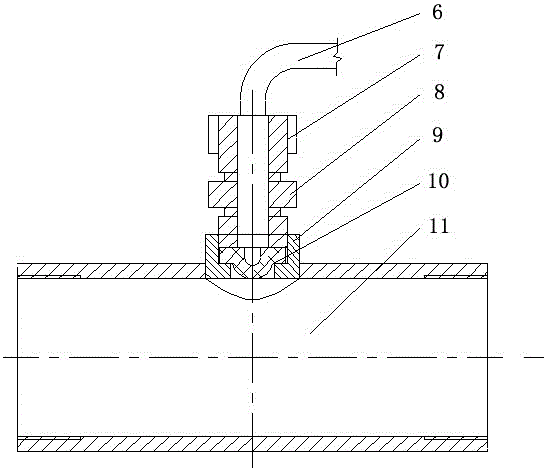

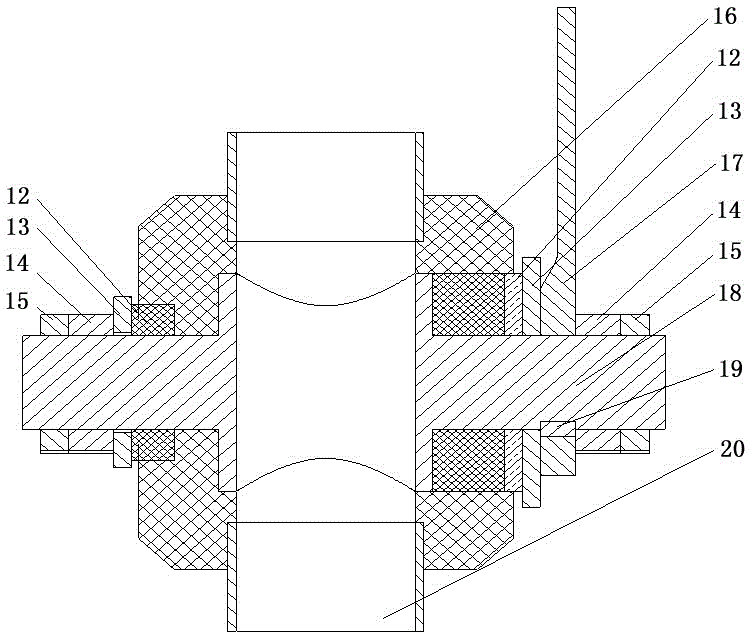

[0070] The backfilling method of the TBM method tunnel or tunnel construction involved in the present invention fully utilizes the technical advantages of mortar and fine stone concrete backfilling, and can be used within the 360° range of the cavity section between the outer wall of the TBM prefabricated lining structure segment and the surrounding rock wall. , completely or partially replace the original pea-gravel grouting backfill to overcome the defects of simple bean-gravel grouting backfill. Specifically, it is realized by the following steps:

[0071] The cavity between the outer wall of the TBM prefabricated lining structure segment and the surrounding rock wall is backfilled in a 360° range, and the following two improvement schemes can be adopted:

[0072] Option 1: backfill with mortar at the bottom arch, backfill with pea gravel grouting at the arches on bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com