Metal corrugated lining plastic steel plate pipe culvert

A corrugated pipe culvert and corrugated technology, which is applied in the field of corrugated pipes, can solve the problems of being short, corroded and restricted in a short time, and achieves the effects of easy mastering, improved service life, and good economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

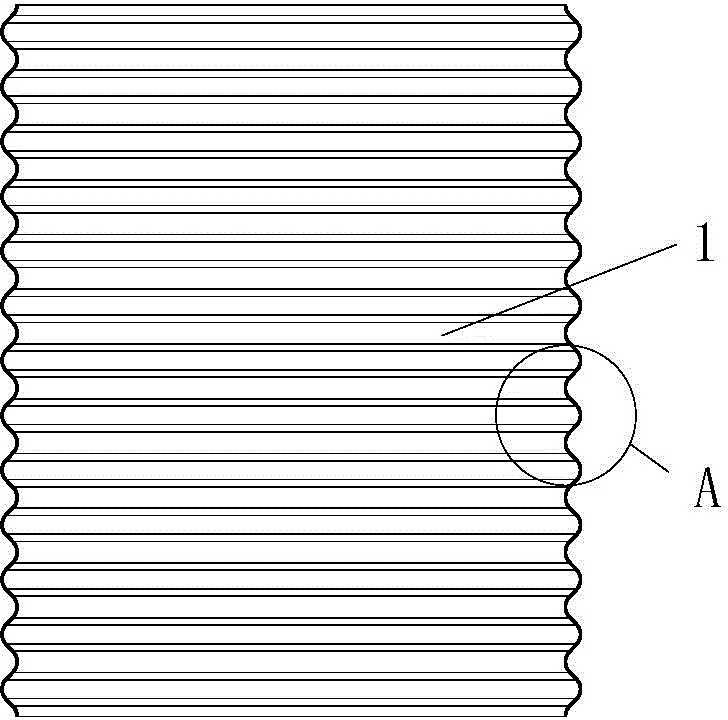

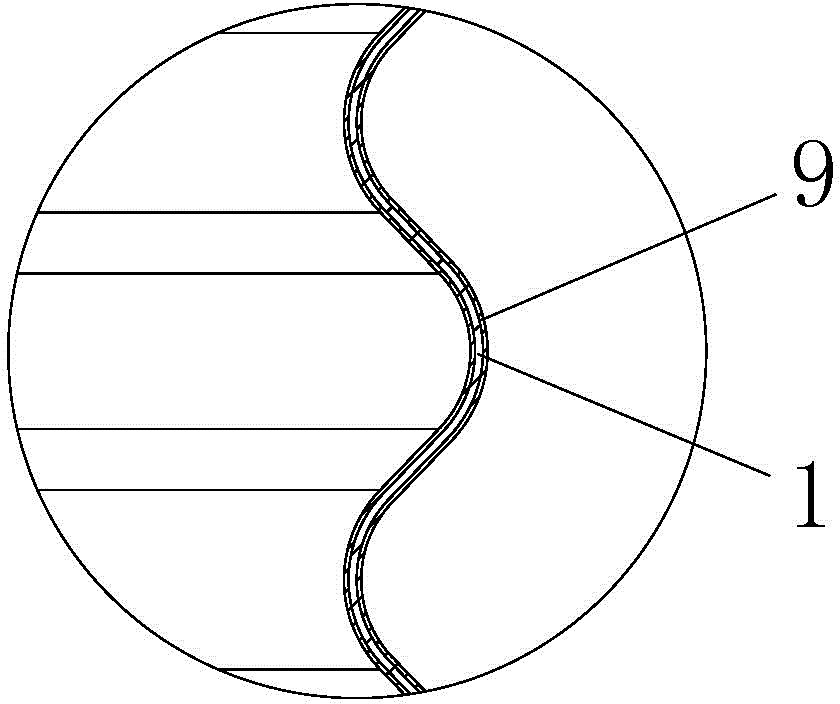

[0024] Such as figure 1 Shown is a schematic structural view of the first embodiment of the metal corrugated plastic-lined steel pipe culvert of the present invention. The metal corrugated plastic-lined steel pipe culvert of this embodiment includes a corrugated pipe culvert body 1 , and an epoxy resin layer 9 bonded integrally with the corrugated pipe culvert body 1 is provided on the inner and outer walls. The thickness of the epoxy resin layer 9 is 0.005-10 mm. Specifically, the thickness of the epoxy resin layer 9 in this embodiment is 1 mm, and the thickness of the epoxy resin layer 9 is set according to actual use requirements.

[0025] In the metal corrugated plastic-lined steel pipe culvert of this embodiment, an epoxy resin layer is provided on the inner and outer walls of the corrugated pipe culvert body, and the epoxy resin layer has the following advantages: 1) There is a strong bond between the corrugated pipe culvert body and Adhesive ability, can be bonded with...

no. 2 example

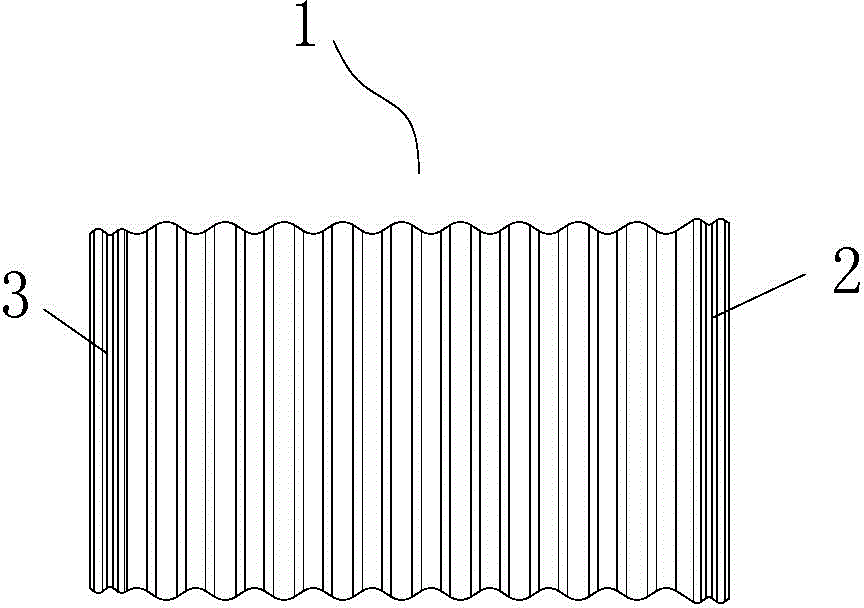

[0027] Such as image 3 As shown, it is a structural schematic diagram of the second embodiment of the metal corrugated plastic-lined steel pipe culvert of the present invention. The metal corrugated plastic-lined steel pipe culvert of this embodiment includes a corrugated pipe culvert body 1 , and an epoxy resin layer 9 bonded integrally with the corrugated pipe culvert body 1 is provided on the inner and outer walls. The thickness of the epoxy resin layer 9 is 0.005-10 mm. Specifically, the thickness of the epoxy resin layer 9 in this embodiment is 1 mm, and the thickness of the epoxy resin layer 9 is set according to actual use requirements.

[0028] In the corrugated pipe culvert body 1 of this embodiment, the corrugated pipe culvert body 1 is provided with wavy linear corrugations, and the two ends of the corrugated pipe culvert body 1 are respectively provided with a socket 2 and an insertion port 3 . The inner diameter of the socket 2 is larger than the outer diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap