Process for injecting terrestrial heat of CO2 mining waste high-temperature gas reservoir

A process method and high-temperature gas technology, applied in the field of oil and natural gas exploration and development, can solve problems such as physical property damage of reservoirs, achieve high permeability, save initial investment in infrastructure construction, and be beneficial to heat exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

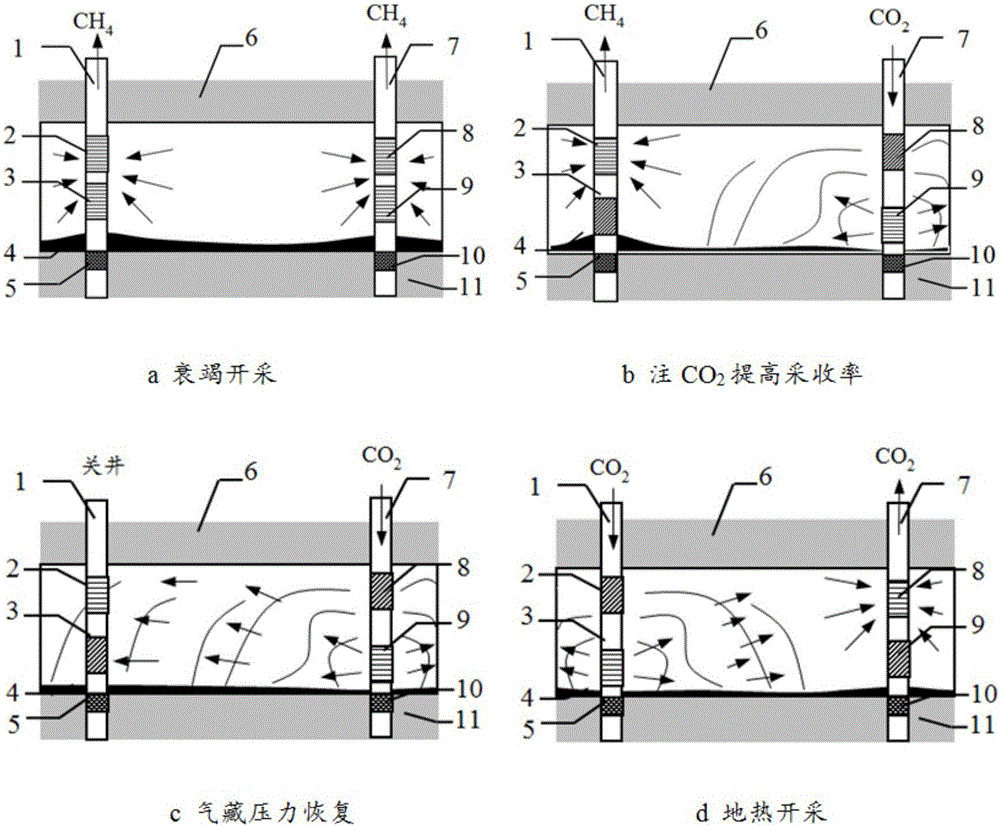

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0034] A CO injection 2 The technical method for exploiting geothermal energy in high-temperature waste gas reservoirs, the specific steps are as follows:

[0035] (1) if figure 1 As shown in a, select a high-temperature gas reservoir with no edge-bottom water or weak edge-bottom water, with a temperature higher than 90°C and potential for geothermal exploitation; design the well pattern according to the gas field development standard for natural gas exploitation; take two adjacent wells as an example, drill Vertical well A1 and vertical well B7 run through the entire gas reservoir, respectively open all the perforations in well sections 2, 3, 8, and 9, and carry out natural gas production in the whole well section; until the natural gas recovery rate reaches 80%, the reservoir is reduced to Exhaustion stress.

[0036] (2) if figure 1 As shown in b, change the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com