Automatic control method of grain drying system

A drying system and grain dryer technology, applied in drying, drying machine, drying solid materials and other directions, can solve problems such as inability to control, and achieve the effect of improving efficiency and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings and specific embodiments.

[0015] The following are specific embodiments of the present invention.

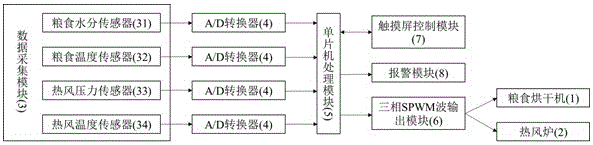

[0016] as attached figure 1 As shown, an automatic control method of a grain drying system, the grain drying system includes a grain dryer 1 and a hot stove 2. Described automatic control method realizes information collection by data collection module 3, after A / D converter 4 converts the analog value of collection into digital quantity, input to single-chip processing module 5, single-chip processing module 5 according to preset value and collection value, By adjusting the output pulse of the three-phase SPWM wave output module 6 connected with the grain dryer 1 and the hot blast stove 2, and then adjusting the working frequency of the grain dryer 1 and the hot blast stove 2, the grain dryer 1 and the hot blast Automatic regul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com