Ultrasonic detection method for different technical stages of composite blade ring

A composite material and ultrasonic testing technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves. It can solve the problems of non-destructive testing methods that have not been reported and are difficult to apply, achieve high signal-to-noise ratio, improve detection sensitivity, and avoid influencing factors. many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

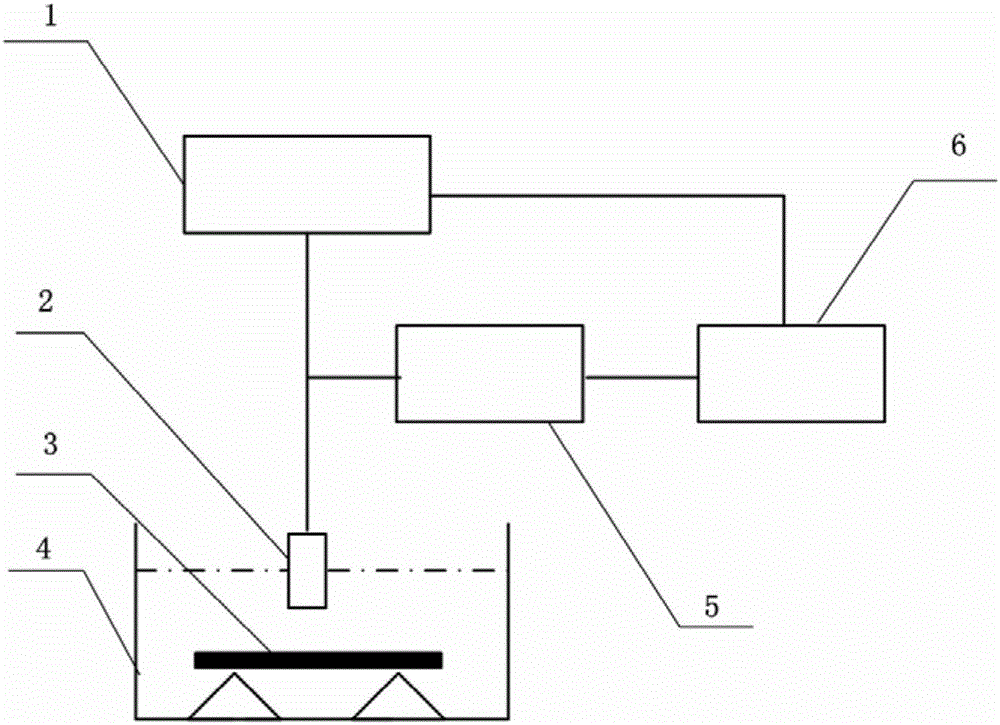

[0026] For attached figure 2 The silicon carbide fiber-reinforced titanium-based composite material TC17 integral leaf ring with an outer diameter of Φ600 mm is subjected to ultrasonic testing, and the pulse-echo type water immersion focused ultrasonic C-scan testing system used in the ultrasonic testing method includes an ultrasonic flaw detector (1) , water immersion focusing probe (2), inspected part (3), water tank (4), automatic scanner (5) and computer (6), see attached figure 1 .

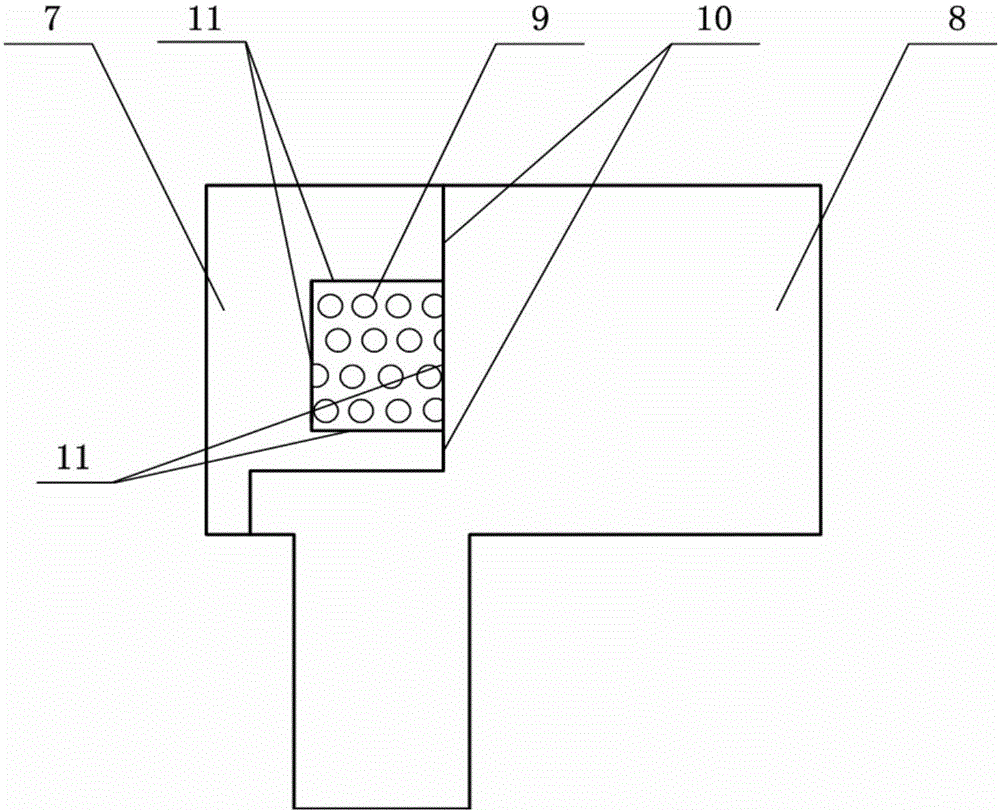

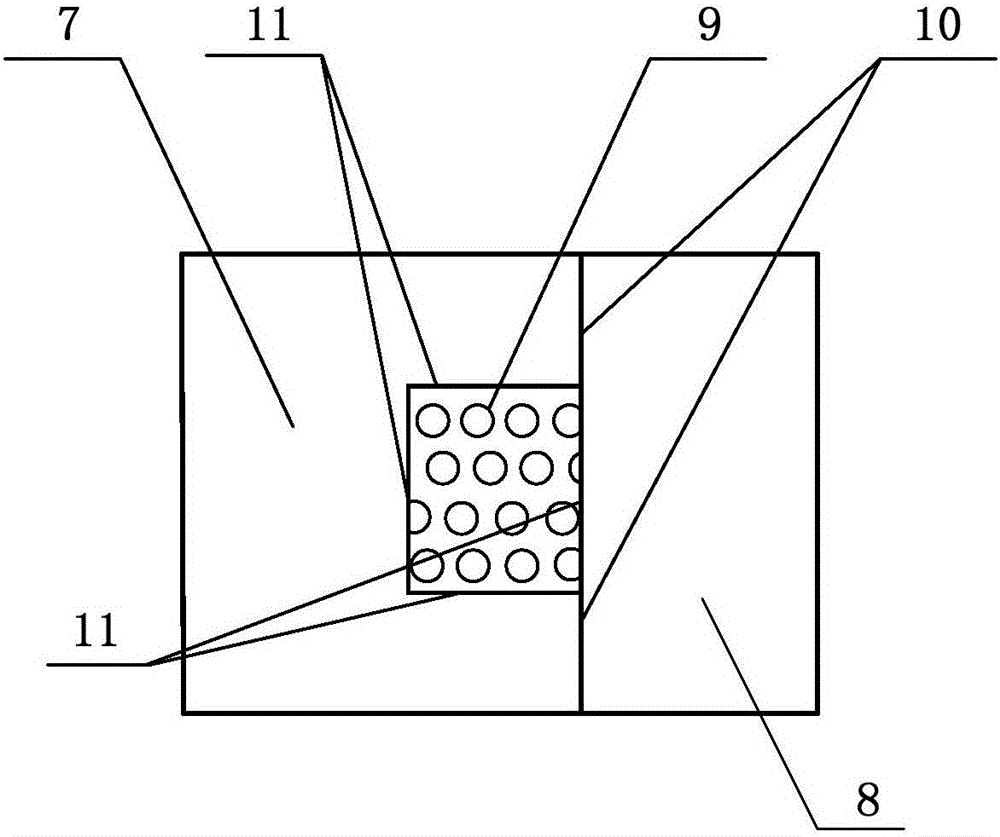

[0027] The TC17 integral leaf ring is first made of titanium alloy inner ring (7) and outer ring (8) forgings by forging. ) is wound in the groove of the forging of the inner ring (7), and then the inner and outer rings are combined by hot isostatic pressing, and the metal / metal interface ( 10), and the detection of the metal / fiber interface (11) between the titanium alloy and the silicon carbide fiber filament (9), and finally finish machining to complete the production of the part.

[0...

Embodiment 2

[0048] For attached image 3 The silicon carbide fiber-reinforced titanium-based composite material TC17 double-shoulder ring with an outer diameter of Φ152 mm is subjected to ultrasonic testing. The pulse-echo type water immersion focused ultrasonic C-scan testing system used in the ultrasonic testing method includes an ultrasonic flaw detector (1), Water immersion focusing probe (2), inspected part (3), water tank (4), automatic scanner (5) and computer (6), see attached figure 1 .

[0049] The TC17 double-shoulder ring is first made of titanium alloy inner ring (7) and outer ring (8) forgings by forging. Wrapped in the groove of the forging of the inner ring (7), then hot isostatic pressing is used to combine the inner and outer rings into one, and the metal / metal interface (10 ), and the detection of the metal / fiber interface (11) between the titanium alloy and the silicon carbide fiber filament (9).

[0050] Using the method of the present invention to carry out ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com