Process of integrally winding foil coils with low-voltage windings of axially split transformers

A technology for splitting transformers and low-voltage windings, applied in the field of transformers, can solve the problems of affecting the short-circuit resistance of coils, wasting man-hours and materials, and poor oil flow channels, so as to save assembly time, reduce unbalance rate, and smooth oil flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

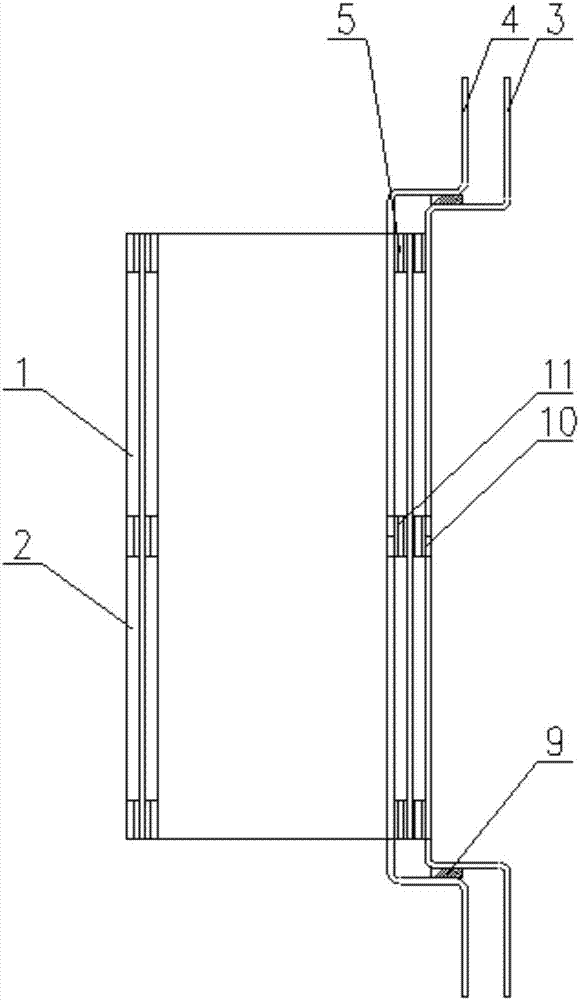

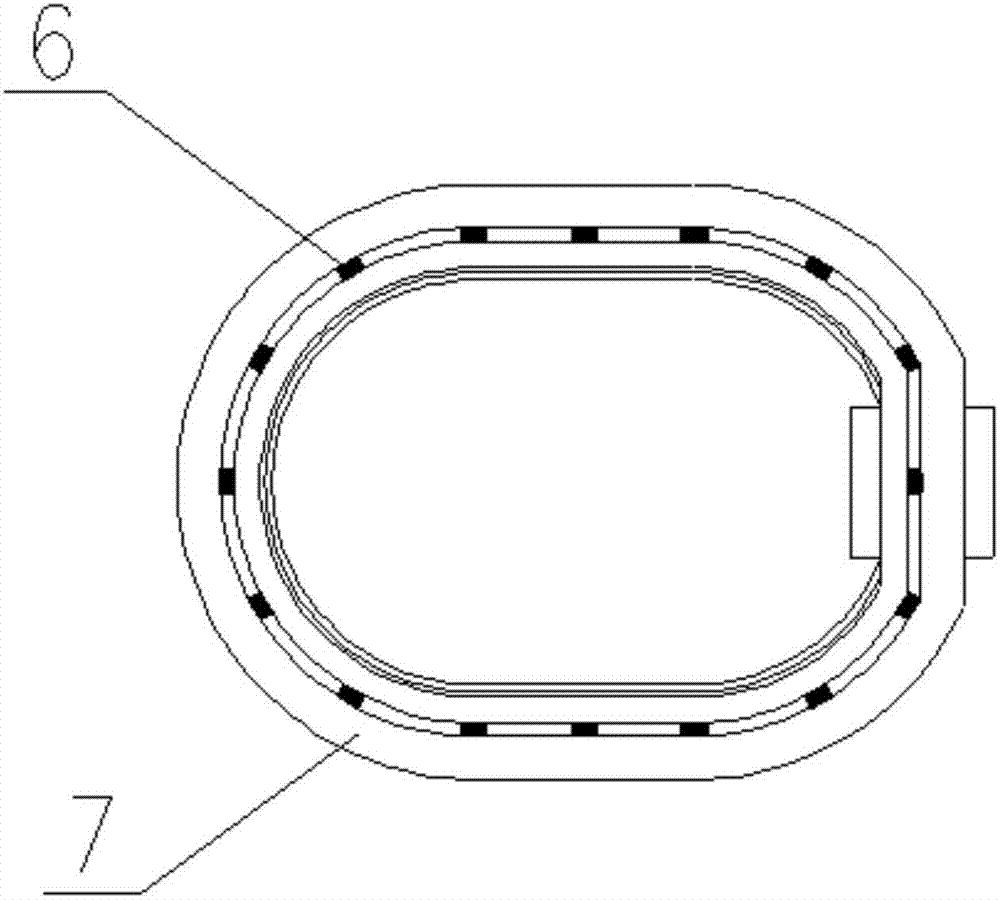

[0082] Embodiment 1. The process of axially splitting the low-voltage winding of the transformer to integrally wind the foil coil is characterized in that it includes the following steps

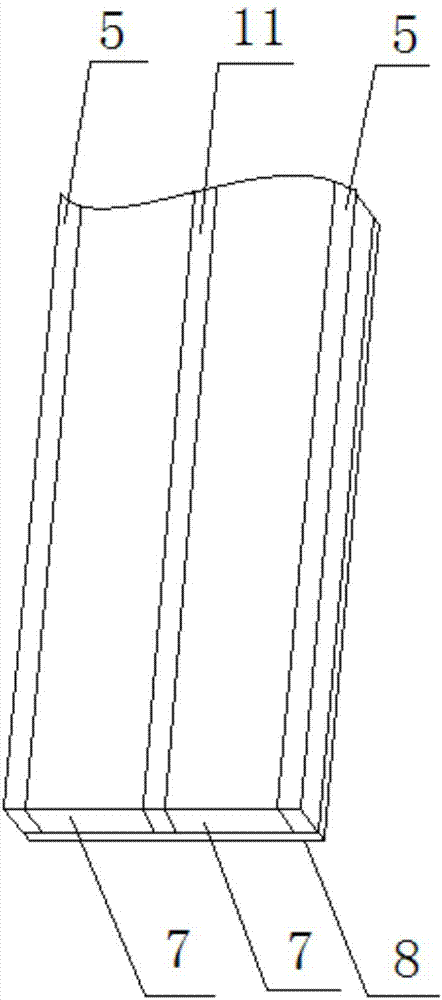

[0083] Step 1. According to the requirements of the drawings, select the same two shafts of metal foil and one shaft of insulating paper 8, where the width of insulating paper 8 is 30mm larger than the sum of the widths of the two shafts of metal foil;

[0084] Step 2. Hang the two-axis metal foil on the wire reel shelf of the double-layer foil winding machine at the same time, put the insulating paper 8 on the wire reel shelf, and pull the starting end of the two-axis metal foil and the starting end of the insulating paper 8. From the beginning to the worktable, the starting edge of the two-axis metal foil and the starting edge of the insulating paper 8 are on the same straight line, and the two-axis metal foil is symmetrically laid on the upper surface of the insulating paper 8, and the gap...

Embodiment 2

[0104] Embodiment 2, the process of axially splitting the low-voltage winding of the transformer to integrally wind the foil coil, is characterized in that it includes the following steps

[0105] Step 1. According to the requirements of the drawings, select the same two shafts of metal foil and one shaft of insulating paper 8, where the width of insulating paper 8 is 40mm larger than the sum of the widths of the two shafts of metal foil;

[0106] Step 2. Hang the two-axis metal foil on the wire reel shelf of the double-layer foil winding machine at the same time, put the insulating paper 8 on the wire reel shelf, and pull the starting end of the two-axis metal foil and the starting end of the insulating paper 8. From the beginning to the worktable, the starting edge of the two-axis metal foil and the starting edge of the insulating paper 8 are on the same straight line, and the two-axis metal foil is symmetrically laid on the upper surface of the insulating paper 8, and the ga...

Embodiment 3

[0126] Embodiment 3, the process of axially splitting the low-voltage winding of the transformer to integrally wind the foil coil is characterized in that it includes the following steps

[0127] Step 1. According to the requirements of the drawings, select the same two shafts of metal foil and one shaft of insulating paper 8, where the width of insulating paper 8 is 45mm larger than the sum of the widths of the two shafts of metal foil;

[0128]Step 2. Hang the two-axis metal foil on the wire reel shelf of the double-layer foil winding machine at the same time, put the insulating paper 8 on the wire reel shelf, and pull the starting end of the two-axis metal foil and the starting end of the insulating paper 8. From the beginning to the worktable, the starting edge of the two-axis metal foil and the starting edge of the insulating paper 8 are on the same straight line, and the two-axis metal foil is symmetrically laid on the upper surface of the insulating paper 8, and the gap ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com