A continuous composite device for winding laminated cell units

A composite device, winding technology, applied in the direction of electrical components, circuits, secondary batteries, etc., can solve the problems of large loss of mechanical equipment, irregularity, local composite of unevenness of flat pressing surface, etc., to increase the service life, The effect of reducing process loss and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

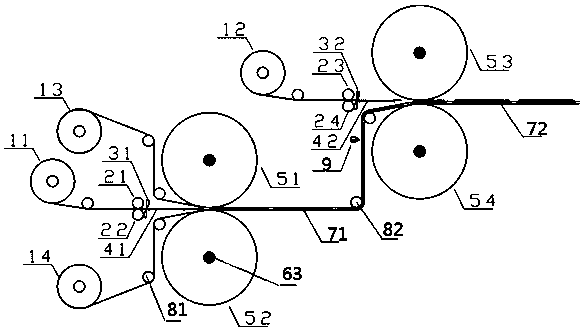

[0024] Such as figure 1 As shown, the continuous composite device of the wound-type laminated cell unit in this embodiment includes a discharge device, a positioning mechanism and a pressure roller composite mechanism. The discharge device includes an anode discharge mechanism 11, a cathode discharge mechanism 12, an upper Diaphragm discharge mechanism 13 and lower diaphragm discharge mechanism 14, the pressure roller composite mechanism includes a front pressure roller composite mechanism and a rear pressure roller composite mechanism, and the front pressure roller composite mechanism is used to discharge materials from the anode discharge mechanism 11 and upper diaphragm discharge The anode sheet, the upper diaphragm and the lower diaphragm obtained by the mechanism 13 and the lower diaphragm feeding mechanism 14 are combined to form the anode composite pole belt 71, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com