Current setting method for fault-tolerant control on one-phase winding open-circuit fault of 45-degree phase belt angle four-phase permanent-magnet synchronous motor

A permanent magnet synchronous motor, current setting technology, applied in the direction of the current controller, etc., can solve the problem of weak torque output capacity of the motor, and achieve the effect of improving the torque output capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

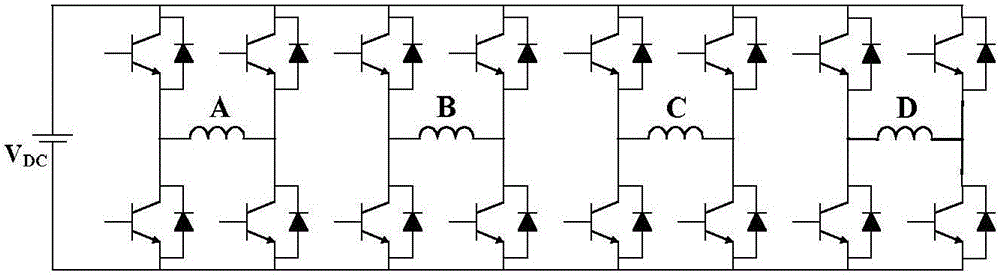

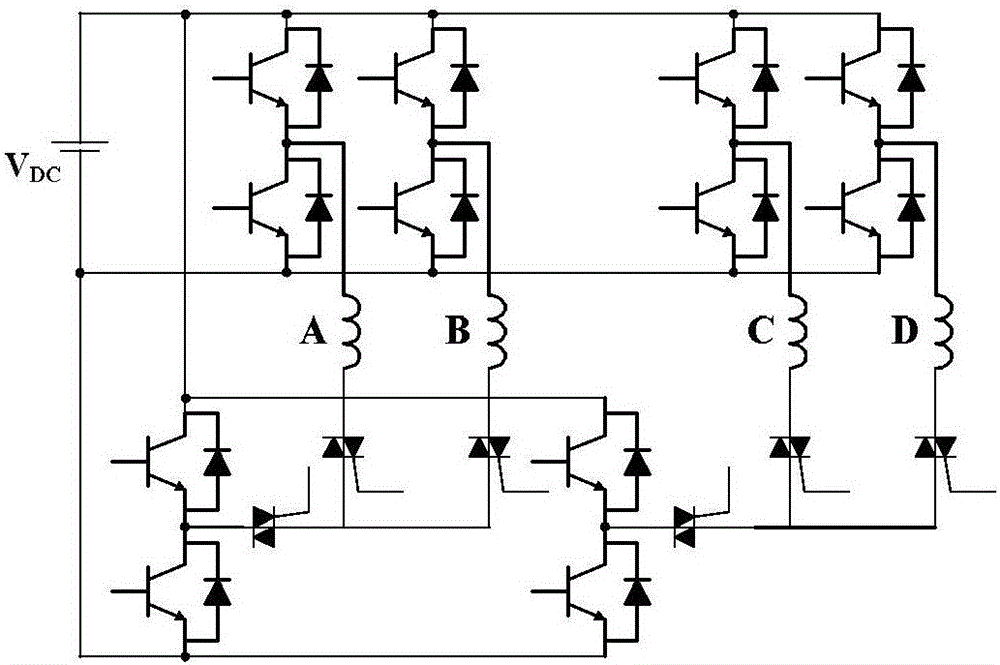

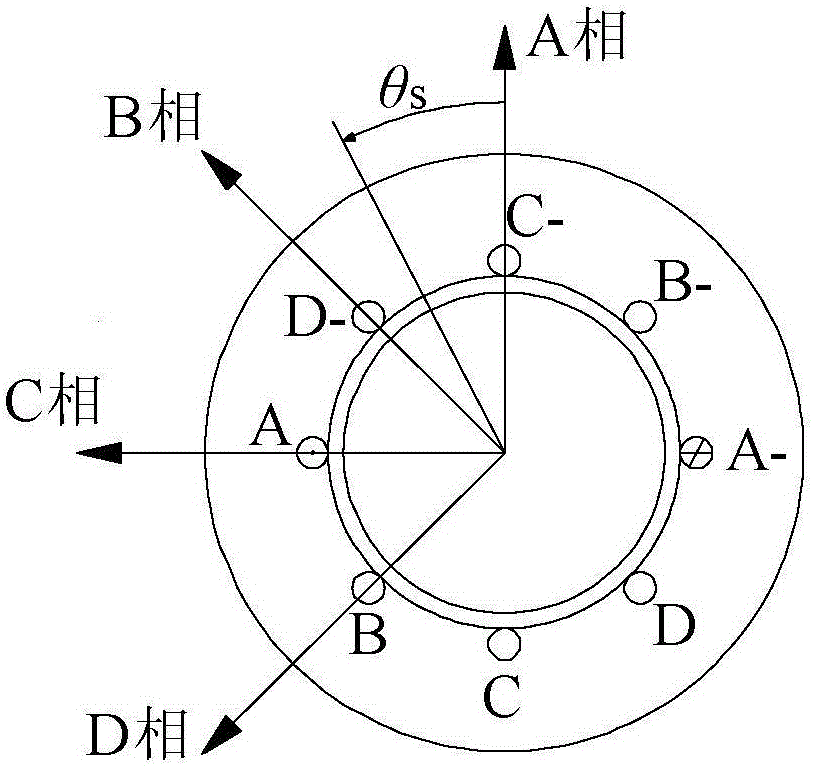

[0036] Specific implementation mode one: the following combination Figure 1 to Figure 7 Describe this embodiment, the current setting method for the fault-tolerant control of one-phase winding open-circuit fault of a four-phase permanent magnet synchronous motor with a 45° phase angle described in this embodiment, this embodiment provides that the current amplitude remains unchanged before and after adjustment Case.

[0037] The schematic diagram of the power supply principle of a four-phase permanent magnet synchronous motor with a phase angle of 45° is shown in figure 1 with figure 2 as shown, figure 2 The disclosed topology is described in detail in the Chinese patent "Four-Phase Six-Bridge Inverter with High Fault Tolerance" with publication number CN103051226A. The schematic diagram of the winding space of a four-phase permanent magnet synchronous motor with a 45° phase belt angle is shown in image 3 shown. The number of turns in series for each phase of the four...

specific Embodiment approach 2

[0083] Specific implementation mode two: this implementation mode will further illustrate implementation mode one, 1' m = I m . And provide a specific embodiment.

[0084] Adopting the current setting method for fault-tolerant control of one-phase winding open-circuit faults of four-phase permanent magnet synchronous motors with 45° phase angles according to the present invention can significantly improve the torque output capability of the motor after a fault, specifically manifested in: Under the premise of not increasing the current excitation amplitude, the torque output by the traditional fault-tolerant control method after a one-phase open-circuit fault is 63.3% of the normal state, while using the method of the present invention, the output torque after a one-phase open-circuit fault is 68.3% of normal conditions.

specific Embodiment approach 3

[0085] Embodiment 3: This embodiment will further explain Embodiment 1. In the case of an open-circuit fault of a phase winding of the motor, the inverter adjusts the phase relationship of the remaining winding currents of each phase according to the method of the present invention, and the amplitude of the current Simultaneous scaling can be performed in a proportional relationship.

[0086] I' m = kI m , where k is the scaling factor, and k is a positive number.

[0087] If the D-phase winding is open, if k=1.2, the A, B, and C three-phase currents are all adjusted to 1.2 times the original.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com