Rack type vertical elevator operation checking-controlling and positioning system

A technology for positioning systems, lifts, used in the direction of elevators, transport and packaging, elevators in buildings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below with reference to accompanying drawing, the present invention is described in detail:

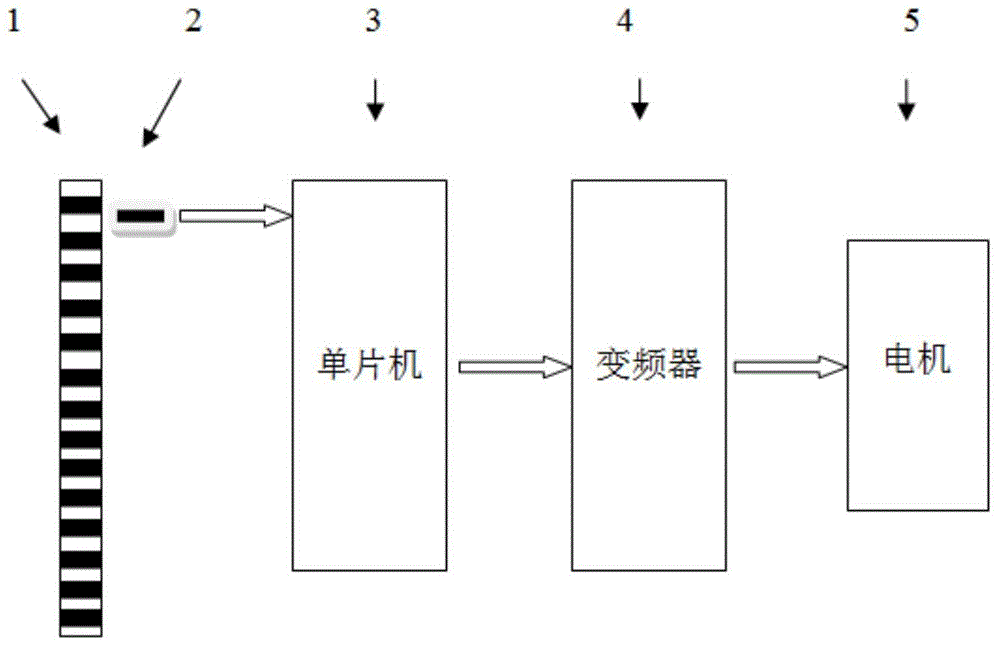

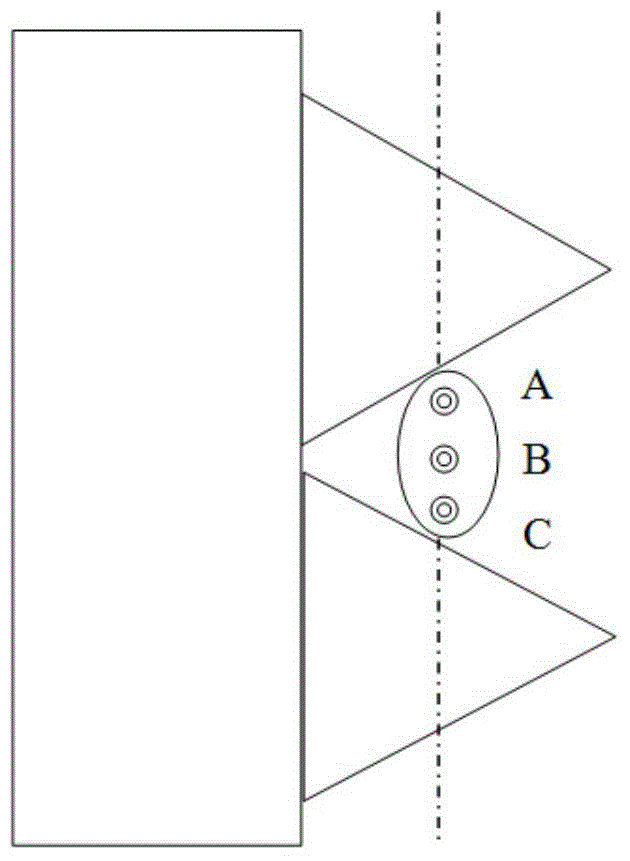

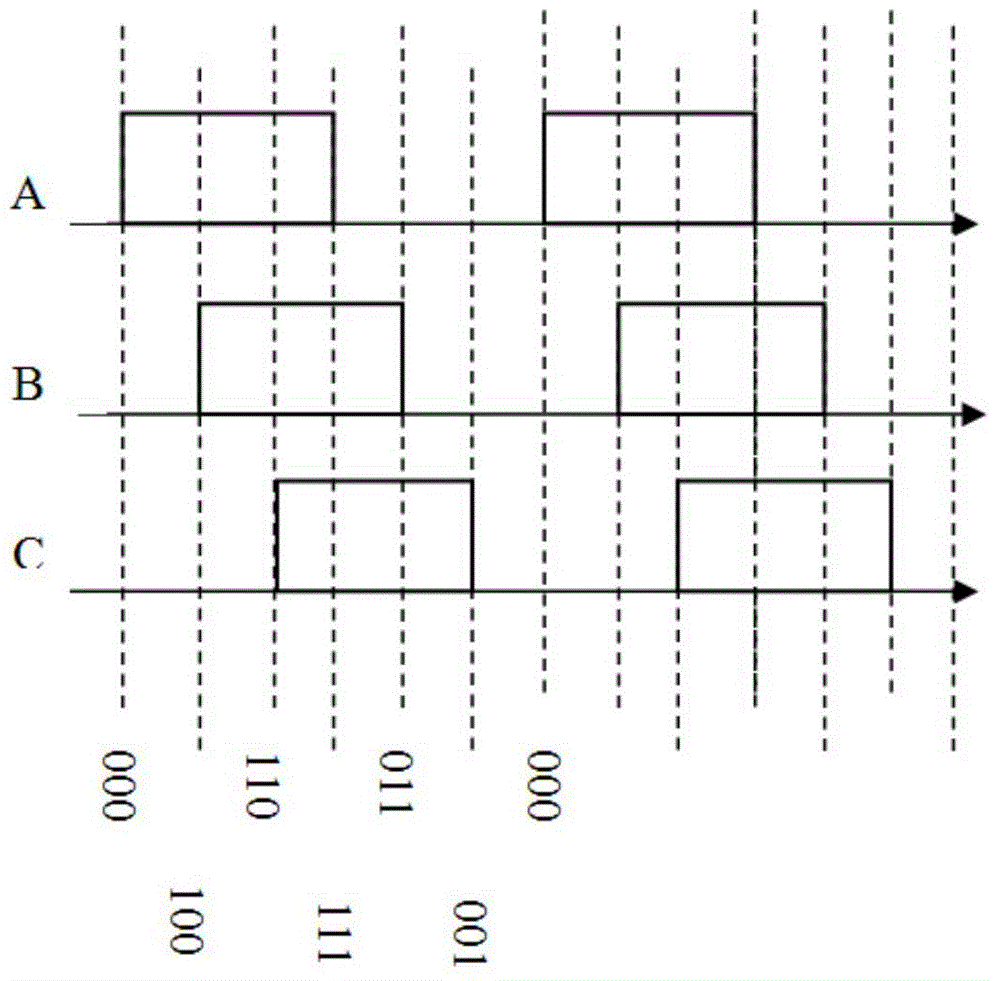

[0024] The rack-type vertical lift is composed of a fixed derrick and a movable cage. The rack is fixed on the derrick, and the cage is fixed with a power motor, a gear transmission device, a frequency converter electric control cabinet and an operation console. Such as figure 1 As shown, it is a specific implementation system architecture of the present invention. The rack-type vertical elevator operation inspection and positioning system includes: a derrick rack 1, a tooth number sensor and a detection circuit 2, a single-chip microcomputer 3, a frequency converter 4 and a motor 5 that drives the elevator cage .

[0025] The derrick rack 1 is fixed on the derrick; the tooth number sensor and detection circuit 2, the single chip microcomputer 3, the frequency converter 4, and the motor 5 are all fixed on the elevator cage, and can move up and down together with the elevator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com