Interior wall putty powder and preparation method thereof

A technology of interior wall putty powder and starch, which is applied in the direction of filling slurry, etc., can solve the problems of interior wall peeling, pulverization, user troubles, and random use, etc., to improve crack resistance, reduce putty cost, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

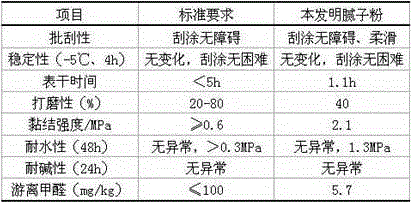

Examples

Embodiment 1

[0028] Example 1 An interior wall putty powder, the following raw materials are taken in parts by weight (10kg / part): 15 parts of microcrystalline cellulose, 7 parts of butyl acrylate, 40 parts of ash calcium, 12 parts of polyvinyl alcohol, 5 parts of polyvinyl chloride Parts, 14 parts of soluble starch, 15 parts of zeolite, 83 parts of heavy calcium carbonate, 3 parts of accelerator, 1 part of anti-mold and fungicide.

[0029] A kind of preparation method of interior wall putty powder is:

[0030] (1) The zeolite is crushed, ground, and passed through a 500-mesh sieve to obtain zeolite powder for later use;

[0031] (2) Place gray calcium and heavy calcium carbonate in a drying oven, dry at 105°C for 2 hours, and set aside;

[0032] (3) Grinding the dried raw materials in step (2) with polyvinyl alcohol, polyvinyl chloride, soluble starch and microcrystalline cellulose respectively, passing through a 250-mesh sieve, and set aside;

[0033] (4) Put the raw materials processe...

Embodiment 2

[0036] Example 2 An interior wall putty powder, the following raw materials are taken in parts by weight (6kg / part): 20 parts of microcrystalline cellulose, 11 parts of butyl acrylate, 46 parts of gray calcium, 16 parts of polyvinyl alcohol, 10 parts of polyvinyl chloride Parts, 20 parts of soluble starch, 21 parts of zeolite, 95 parts of heavy calcium carbonate, 6 parts of accelerator, 4 parts of anti-mold and fungicide.

[0037] A kind of preparation method of interior wall putty powder is:

[0038] (1) The zeolite is crushed, ground, and passed through a 900-mesh sieve to obtain zeolite powder for later use;

[0039] (2) Place gray calcium and heavy calcium carbonate in a drying oven, dry at 145°C for 5 hours, and set aside;

[0040] (3) Grinding the dried raw materials in step (2) with polyvinyl alcohol, polyvinyl chloride, soluble starch and microcrystalline cellulose respectively, passing through a 450-mesh sieve, and set aside;

[0041] (4) Place the raw materials pro...

Embodiment 3

[0044] Example 3 An interior wall putty powder, the following raw materials are taken in parts by weight (9kg / part): 17 parts of microcrystalline cellulose, 8 parts of butyl acrylate, 42 parts of ash calcium, 13 parts of polyvinyl alcohol, 7 parts of polyvinyl chloride Parts, 16 parts of soluble starch, 17 parts of zeolite, 86 parts of heavy calcium carbonate, 4 parts of accelerator, 2 parts of anti-mold and fungicide.

[0045] A kind of preparation method of interior wall putty powder is:

[0046] (1) The zeolite is crushed, ground, and passed through a 600-mesh sieve to obtain zeolite powder for later use;

[0047](2) Place gray calcium and heavy calcium carbonate in a drying oven, dry at 115°C for 3 hours, and set aside;

[0048] (3) Grinding the dried raw materials in step (2) with polyvinyl alcohol, polyvinyl chloride, soluble starch and microcrystalline cellulose respectively, passing through a 300-mesh sieve, and setting aside;

[0049] (4) Place the raw materials pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com