Antibacterial finishing agent and preparation method and antibacterial application thereof

An antibacterial finishing agent and post-finishing technology, which is used in the preparation of antibacterial finishing agents and in the field of antibacterial applications, can solve the problems of decreased antibacterial rate of fabrics, weak combination of antibacterial finishing agents and fabrics, and poor stability of silver sulfide nanoparticles. achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

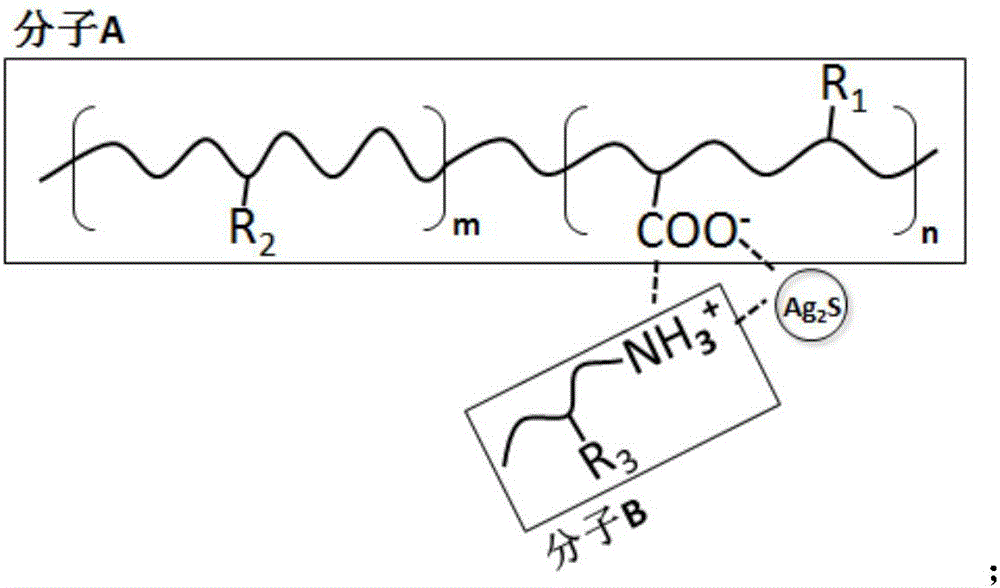

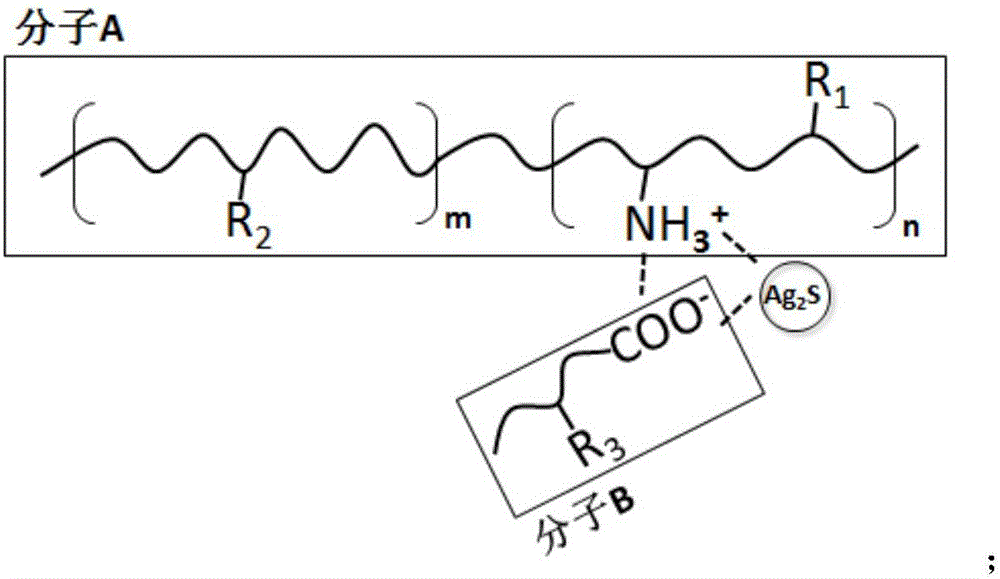

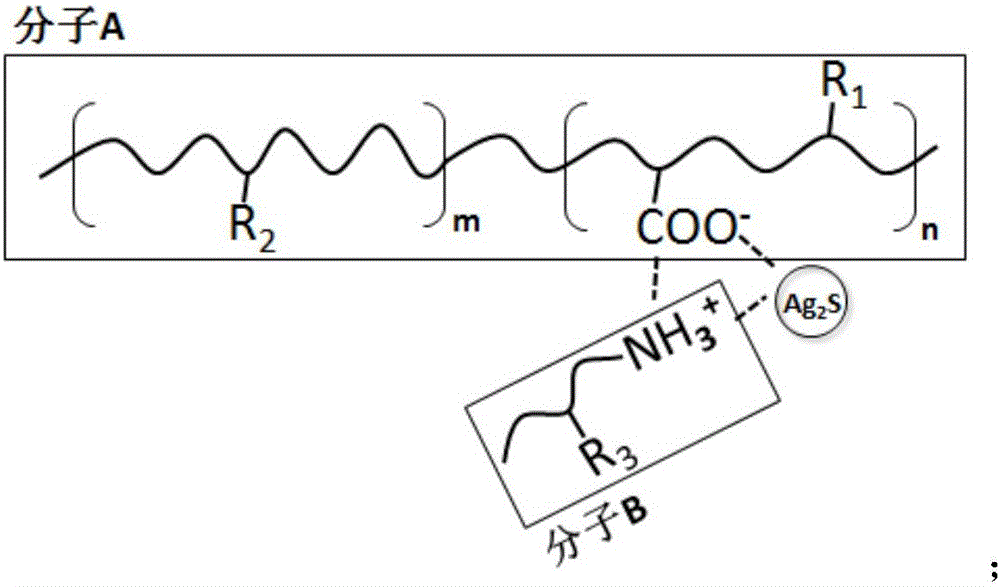

[0059] The preparation method of an antibacterial finishing agent as described above is characterized in that the steps are as follows: mixing the aqueous solution containing the molecule A substance with the aqueous solution containing the molecule B substance, accompanied by stirring, and adjusting the pH value of the reaction system to 4-6, Then add the silver ion salt solution dropwise to the mixed solution, and continue stirring after the dropwise addition; add the metal sulfide sulfur source aqueous solution dropwise, and continue stirring after the dropwise addition, to obtain the aqueous solution of the hybrid material loaded with silver sulfide nanoparticles ;

[0060] The molecule A-containing substance is a molecule A-containing substance containing a carboxyl group in the molecule A or a molecule A-containing substance containing an amino group in the molecule A;

[0061] The molecule B-containing substance is a molecule B-containing substance containing a carboxyl...

Embodiment 1

[0072]A kind of preparation method of antibacterial finishing agent, under the condition of 20 ℃, the aqueous solution of chitosan containing amino groups with a concentration of 0.5% by mass percent and the aqueous solution of n-butyric acid containing carboxyl groups with a concentration of 3% by mass percent are mixed, wherein, The relative molecular weight of chitosan is 240000, and the molecular weight of n-butyric acid is 88.1, and the mol ratio of chitosan and n-butyric acid is 1:0.3, with stirring; Adopt the HCl solution of 0.1mol / L to adjust the pH value of reaction system to 4. Then add dropwise a silver acetate solution with a concentration of 0.005g / mL to the mixture, wherein the molar ratio of silver acetate to chitosan is 0.1:1, and keep stirring for 0.5h after the dropwise addition; the dropwise addition concentration is 0.01 g / mL sodium sulfide aqueous solution, wherein the molar ratio of silver acetate to sodium sulfide is 1:0.5, continue to stir for 1 hour aft...

Embodiment 2

[0075] A kind of preparation method of antibacterial finishing agent, under the condition of 60 DEG C, the carboxymethyl chitosan aqueous solution that the mass percentage concentration is 3% is mixed with the carboxyl group-containing n-valeric acid aqueous solution that mass percentage concentration is 10%, Wherein, the relative molecular weight of carboxymethyl chitosan is 10000, the molecular weight of n-valeric acid is 102.13, the molar ratio of carboxymethyl chitosan and n-valeric acid is 1:1, accompanied by stirring; adopt 0.3mol / L The HCl solution adjusts the pH value of the reaction system to 6, then in the mixed solution, dripping the silver nitrate solution with a concentration of 2g / mL, wherein the mol ratio of silver nitrate and carboxymethyl chitosan is 10:1, after the dropwise addition is completed Continue to stir for 1h; add a concentration of 0.1g / mL potassium sulfide aqueous solution drop by drop, wherein the molar ratio of silver nitrate to potassium sulfide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com