Multifunctional ES fiber spinning oil

A fiber spinning, multi-functional technology, applied in the field of multi-functional spinning oil, can solve the problems of urine retention, poor use comfort, slow urine infiltration speed, etc., and achieve good smoothness and softness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

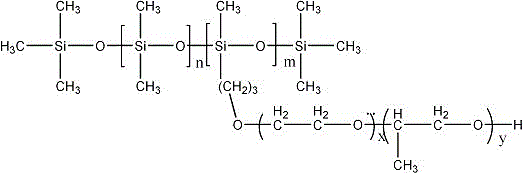

[0025] The multifunctional ES fiber spinning oil of this embodiment is formed by mixing the following components in weight percentage: 12C-8EO-pk, 20%; LAE-4, 20%; polyether silicone oil, 6% ; PCMX, 0.2%; Phenoxyethanol, 2%; Citric acid, 2%; Deionized water to 100%.

[0026] Preparation method: according to the weight percentage, add deionized water into the reaction kettle, heat to 75°C; start stirring, and the stirring speed is 120 rpm; add antistatic agent, emulsifier, polyether silicone oil in sequence, and stir for 10 minutes , to dissolve and mix the components uniformly; cool down to 45°C; add the antibacterial agent, antibacterial synergist, and acid regulator in sequence, and stir for 10 minutes to dissolve and mix the components uniformly; cool to room temperature; discharge.

Embodiment 2

[0028] The multifunctional ES fiber spinning oil of this embodiment is formed by mixing the following components in weight percentage: 12C-8EO-pk, 25%; LAE-4, 15%; polyether silicone oil, 6% ; PCMX, 0.2%; Phenoxyethanol, 2%; Citric acid, 2%; Deionized water to 100%.

[0029] Preparation method: according to the weight percentage, add deionized water into the reaction kettle, heat to 80°C; start stirring, and the stirring speed is 150 rpm; add antistatic agent, emulsifier, polyether silicone oil in sequence, and stir for 15 minutes , to dissolve and mix the components uniformly; cool down to 50°C; add the antibacterial agent, antibacterial synergist, and acid regulator in sequence, and stir for 15 minutes to dissolve and mix the components uniformly; cool to room temperature; discharge.

Embodiment 3

[0031] The multifunctional ES fiber spinning oil of this embodiment is formed by mixing the following components in weight percentage: 12C-8EO-pk, 22%; LAE-4, 18%; polyether silicone oil, 6% ; PCMX, 0.2%; Phenoxyethanol, 2%; Citric acid, 2%; Deionized water to 100%.

[0032] Preparation method: refer to Example 2.

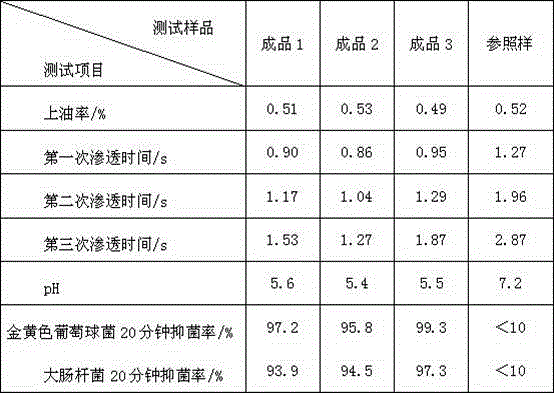

[0033] As a reference comparison, the following table lists the results of testing the obtained nonwoven fabrics after using the above three oil agents to produce fibers and further strengthening them into nonwoven fabrics. In this table, the finished product 1, the finished product 2, and the finished product 3 are respectively the ES fiber nonwoven fabrics manufactured by using the spinning oil of Example 1, Example 2, and Example 3; the reference sample is a commercially available multiple hydrophilic ES Fibrous nonwovens.

[0034] Performance comparison of ES fiber nonwovens

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com