A kind of thermogravimetric analysis method for graphene oxide

A technology of thermogravimetric analysis and graphene, which is applied in the analysis of materials, material weighing, instruments, etc., can solve the problems of inaccurate test results, etc., and achieve the effect of fast test process, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

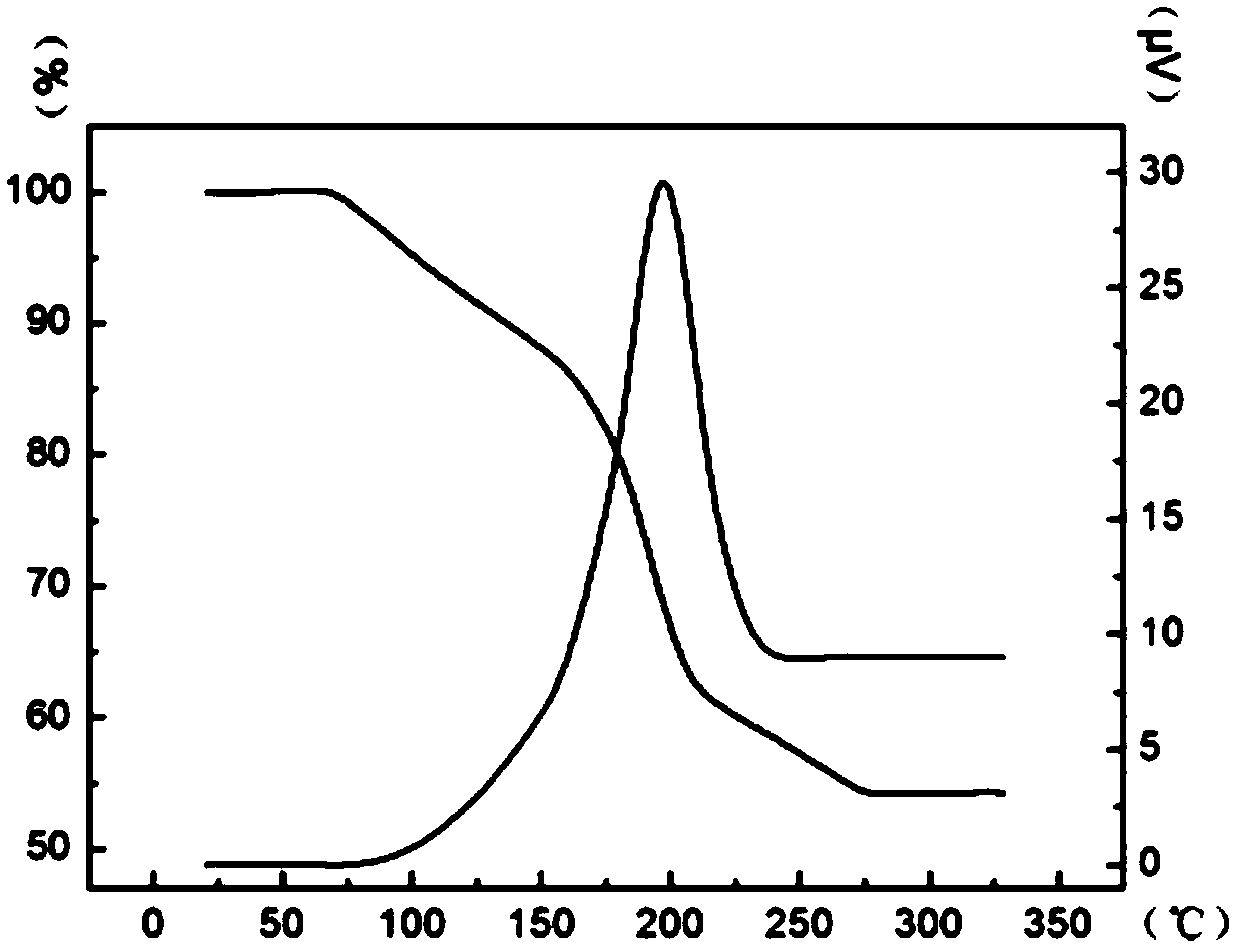

[0015] The thermogravimetric analysis method for graphene oxide that the present embodiment relates to comprises the following steps:

[0016] (1) Pass the graphene oxide powder through a 100-300 mesh sieve, and dry it under vacuum conditions at 50-100°C for 1-6h to constant weight, and put it in a desiccator as a sample for subsequent use;

[0017] (2) Accurately weigh 0.1-50.0 mg of the above-mentioned sample with an electronic balance and put it into a crucible, and then accurately weigh 1.0-100.0 mg of the above-mentioned sample with an electronic balance Or add the powder material formed by doping with quartz into the crucible where the sample is placed and stir and mix evenly; the other crucible is an empty crucible, and then put the two crucibles into the thermogravimetric analyzer at the same time;

[0018] (3) Start the thermal analysis software for thermogravimetric analysis, set the heating range to 25-800°C, the heating rate to 5-200°C / min, preferably 10°C / min or 2...

Embodiment 2

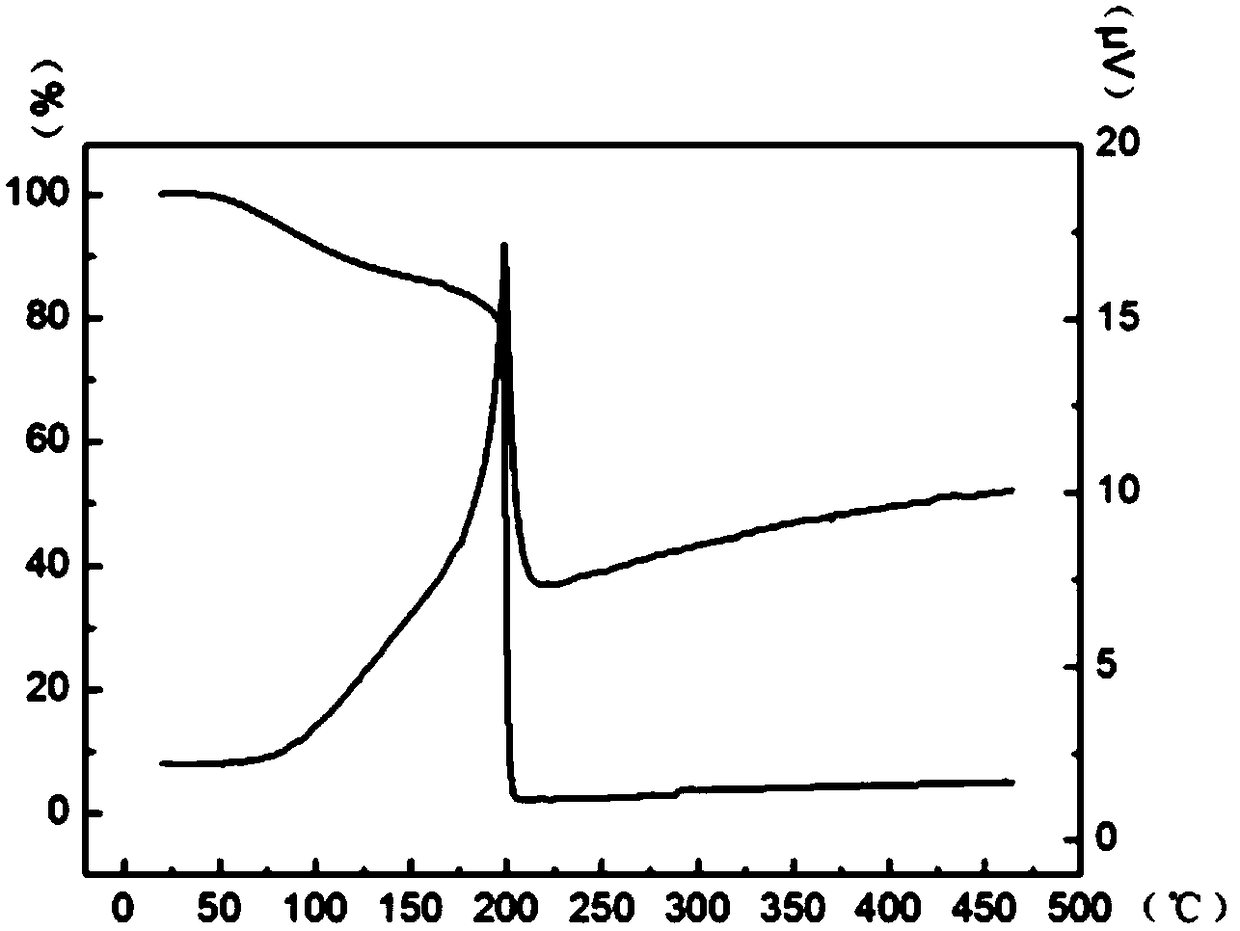

[0020] In this embodiment, the sample without powder material is used as a reference example, and the same thermogravimetric analysis method as in Example 1 is used for analysis and testing, the difference is that only 0.1-50.0 mg of the sample is put into a crucible. In the same way, the other crucible is an empty crucible, and then the two crucibles are placed on the two trays of the sample holder in the thermogravimetric analyzer respectively and the insulation cover is covered to carry out the subsequent steps. The obtained graphene oxide thermogravimetric curve is as follows figure 1 shown.

[0021] Comparing the test results in Example 1 and Example 2, it can be seen that: after the powder material is added in Example 1, the graphene oxide density in the test crucible is reduced, thereby effectively reducing the friction between the graphene oxide powders. Contact, so that when it reaches the reduction temperature, the severity of the reaction is slowed down, and the ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com