Integrated bootstrap high voltage driving chip and technological structure thereof

A high-voltage drive chip, high-voltage technology, applied in the field-effect transistor logic circuit coupling/interface, pulse technology, diodes, etc., can solve the problems of increased chip area, bootstrap capacitor leakage, large on-resistance, etc., to achieve reduction The effect of small chip area, simplified circuit structure, and small conduction voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

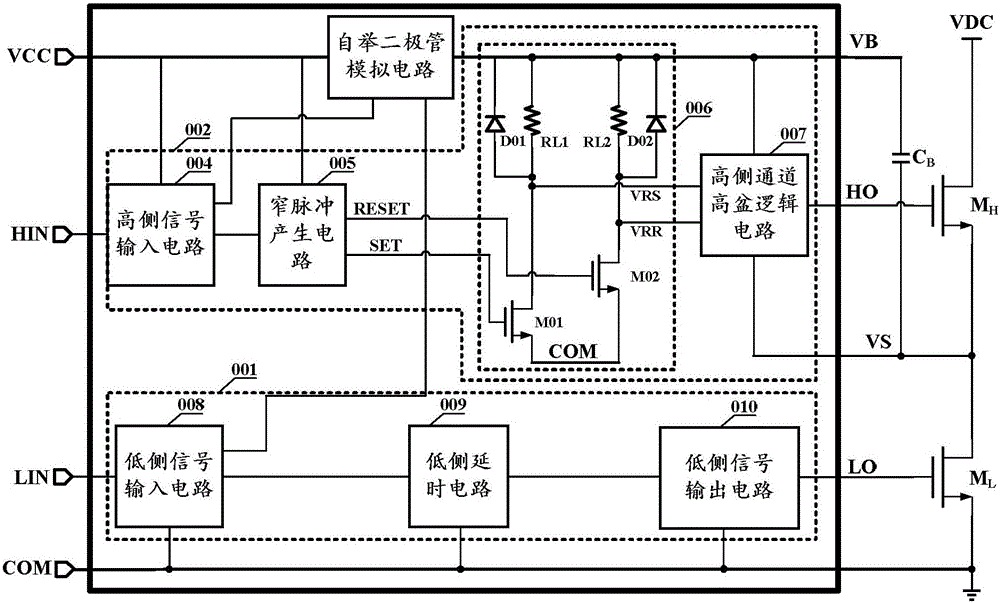

[0043] see image 3 , the process structure of the integrated bootstrap high-voltage driver chip of the present invention includes a base 101 of the first doping type, a buried layer 102 of the second doping type, a well 103 of the second doping type and a well 104 of the first doping type Low basin; first doping type well 105, second doping type buried layer 106, first doping type body contact 107, second doping type source contact 108, second doping type drain contact 109, gate High-voltage switch tube composed of electrode 110 and second doping type well 111; high basin composed of second doping type buried layer 112, second doping type well 113 and first doping type well 114; low basin and high voltage switch The source of the tube is close, and the high basin is close to the drain of the high-voltage switch tube. At least one second doping type well 103 and at least one first doping type well 104 are arranged in the lower basin, and the first doping type well 104 is alwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com