Simulation black fungus section cultivation method

A cultivation method and technology of black fungus, applied in the field of artificial fungus cultivation, can solve the problems of decreased biotransformation rate, large indoor space, and long time for bacteria cultivation, and achieves convenient production and cultivation, low rate of miscellaneous bacteria, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

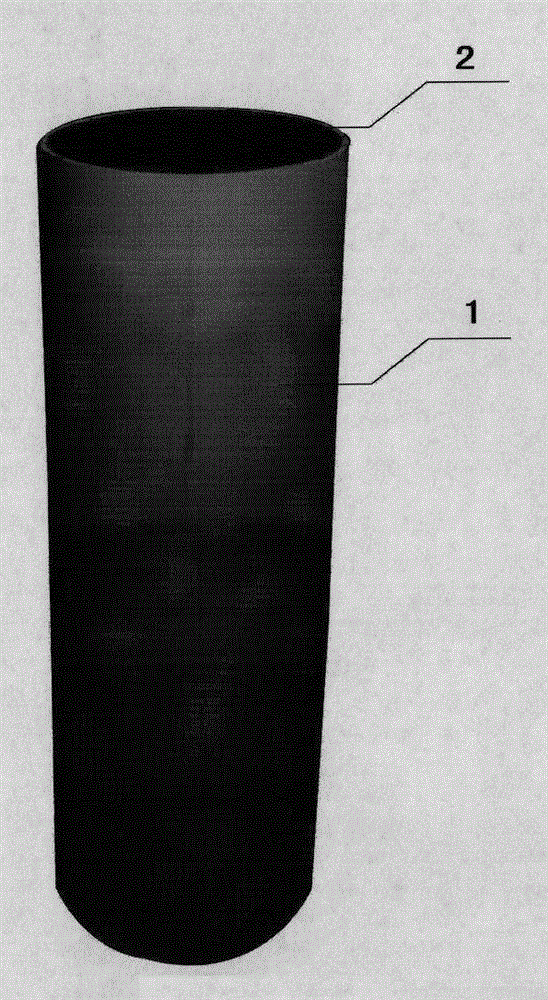

[0008] Simulation black fungus section cultivation method as shown in accompanying drawing; Simulation black fungus section cultivation method, it comprises: 1, phloem 2, xylem; It is characterized in that described phloem 1 is made of plastics, and thickness is 0.2cm to 0.5cm to do plastic tube The artificial fungus section skin is commonly known as bark; the xylem 2 is to use straw and wood processing residues as raw materials, and after all materials are crushed and sieved, the xylem matrix is prepared according to the specified carbon-nitrogen ratio, ph value and water; Then use a special compression packing machine to pack tubes. The diameter of the tube is 5cm to 11cm, and the length is 100cm to 120cm. The tree-like fungus section is drilled to inoculate and cultivate black fungus instead of the fungus section, which can be suitable for the production and cultivation of black fungus.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com