Microfluid cell processing chip and application method thereof

A microfluidic chip and processing chip technology, applied in applications, preservation of human or animal bodies, animal husbandry, etc., can solve the problem that the processing accuracy of channels and cavities cannot be well guaranteed, and the complexity of chip processing and proficiency requirements are increased. High and other problems, to achieve the effect of eliminating complexity, maintaining system pressure drop value, and overcoming complex processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail and completely below in conjunction with the accompanying drawings and embodiments.

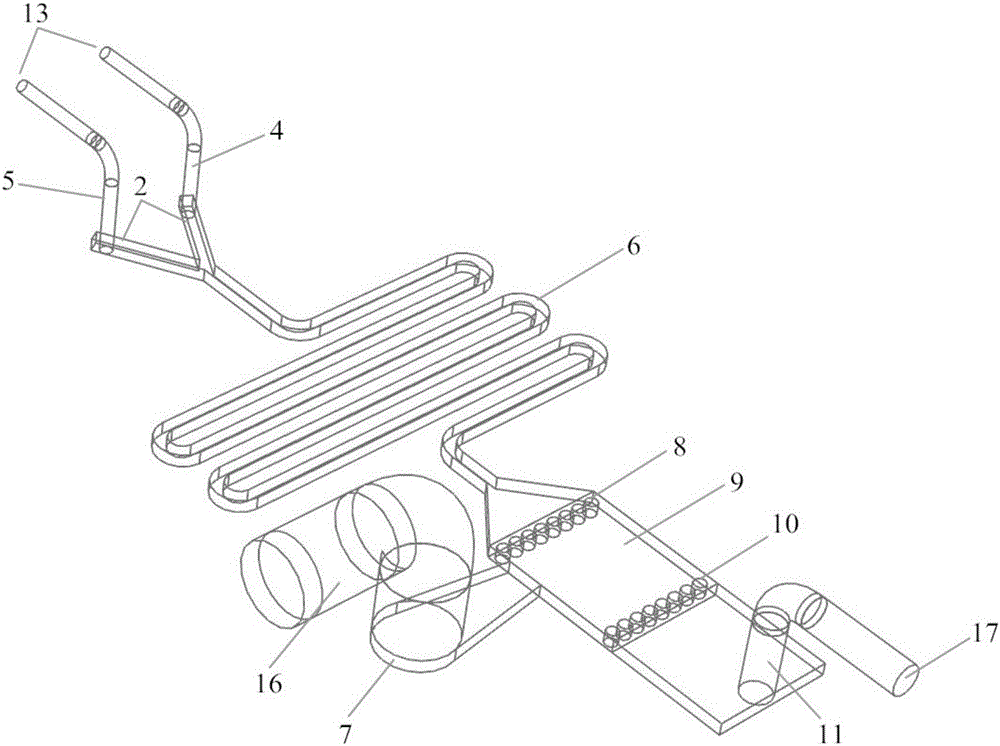

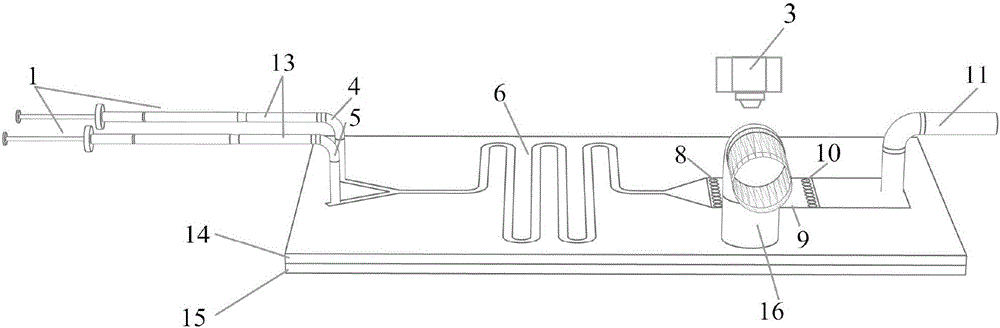

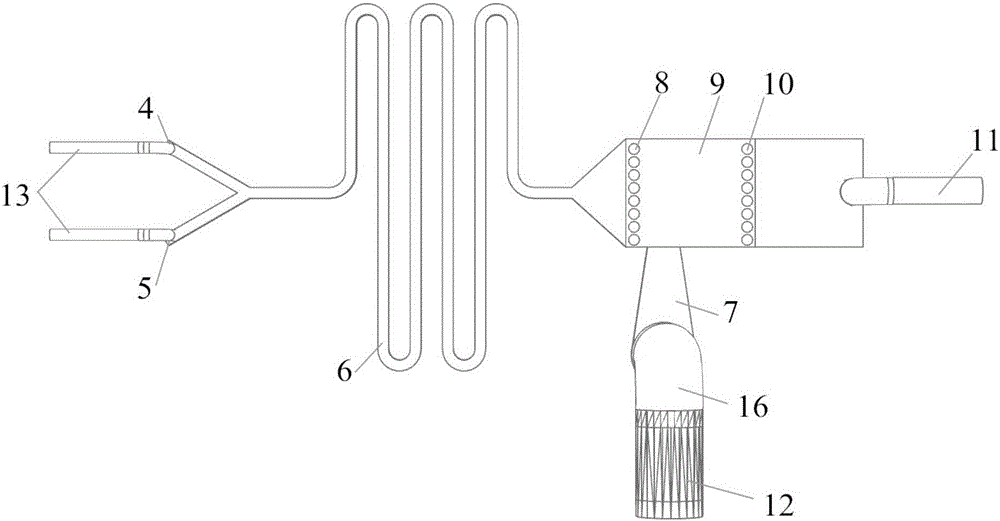

[0035] Such as Figure 1 to Figure 3 As shown, the microfluidic cell processing chip of the present invention consists of a bottom layer 14 and a top layer 15 . The chip body is connected with two dual-channel microinjection pumps through a microfluidic chip capillary, and is installed on the automatic stage of the confocal microscope 3 .

[0036] Such as figure 1 , as shown in 2, the top layer 15 is provided with a serpentine pipeline 6 and a cell operation chamber 9, and the solution inlet of the serpentine pipeline 6 is provided with two inflow passages 2 connected with inlet pipes, and the inlet pipes of the two inflow passages 2 The protective agent inlet 4 and the buffer solution inlet 5 are respectively provided on the top, and the solution outflow channel of the serpentine pipeline 6 is connected to the cell operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com