Ultrasonic atomization ozone sterilization and disinfection machine

An ozone sterilization and ultrasonic atomization technology, applied in disinfection, atomized substances, chemistry, etc., can solve the problems of drug residues, ecological environment damage, poor sterilization and disinfection effects, etc., and achieve no drug residues, low operating costs, sterilization and disinfection good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

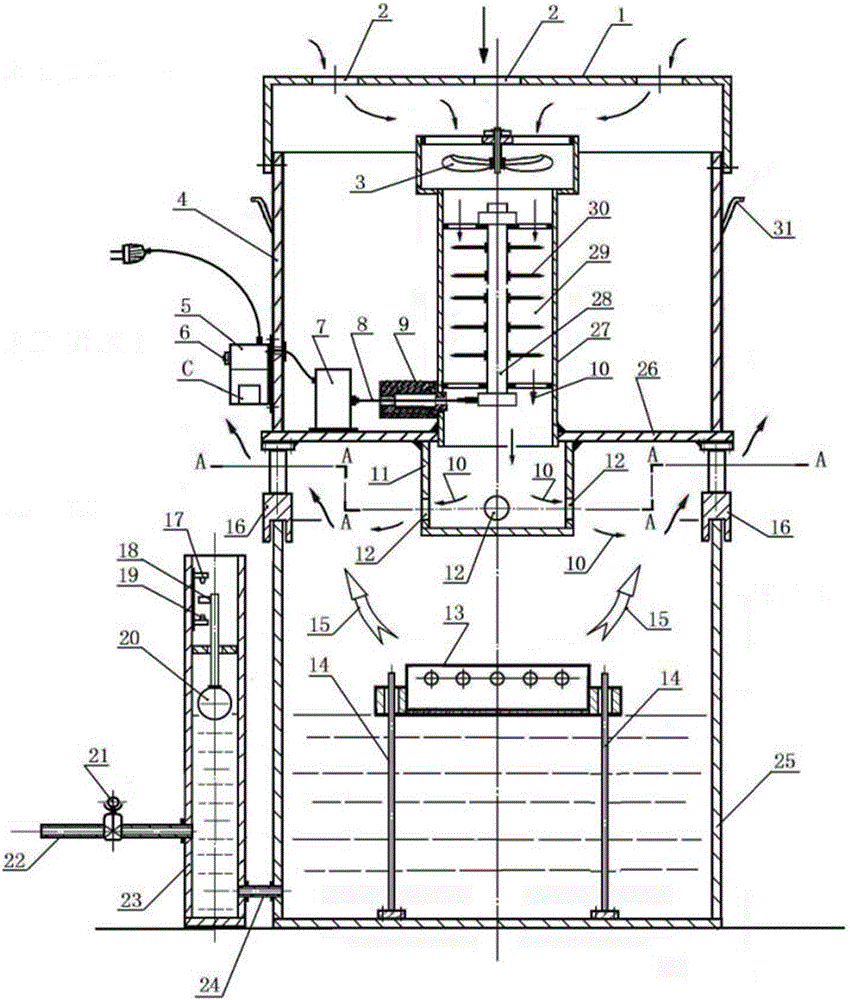

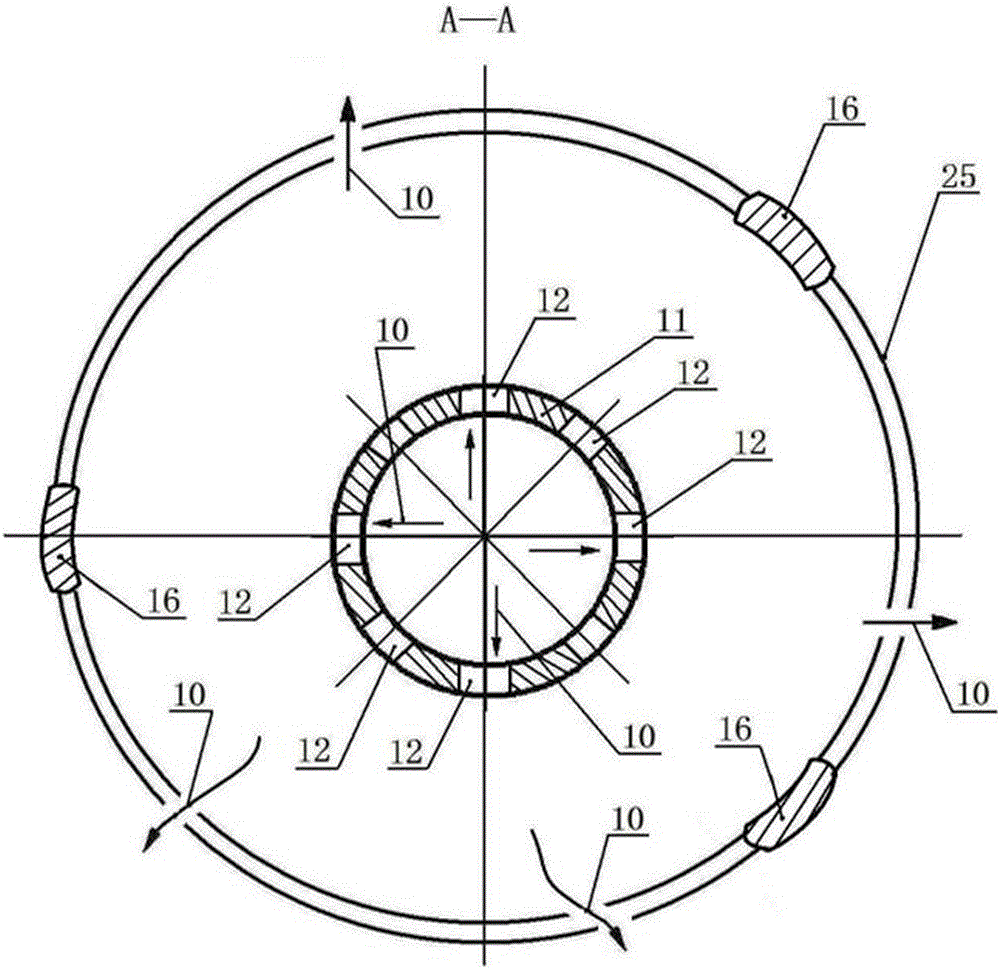

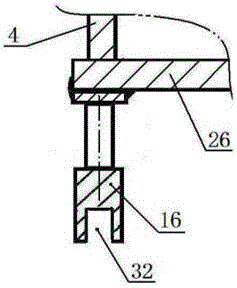

[0020] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0021]The ultrasonic atomization ozone sterilization and disinfection machine proposed by the present invention mainly consists of a water tank 25, an ultrasonic atomizer 13, a water level controller 23, a main box 4 fitted on the water tank 25, a high-voltage ionization cylinder 27, and a high-frequency high-voltage power supply 7 The water level controller 23 is composed of a water inlet pipe 22 equipped with a solenoid valve 21, a lever 18 connected to the float 20, and a set of wire-connected normally closed contact micro-switches 17 and normally open contact micro-switches. 19 and AC contactor C, the bottom of the water tank 25 is equipped with a connecting pipe 24, the other end of the connecting pipe 24 is connected to the water level controller 23, the positioning slide bar 14 is fixedly installed in the water tank 25, and the ultrasonic atomizer 13 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com