Method for manufacturing liquid drop self-driven microreactor and microreactor manufactured through method

A micro-reactor, self-driven technology, applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, chemical/physical/physical-chemical processes, etc. Expensive equipment and other issues to achieve the effect of improving efficiency, simplifying auxiliary equipment, and solving the lack of precision of the flow channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 The preparation method of a kind of droplet self-driven microreactor of the present invention, comprises the following steps:

[0029] 1) Preparation of superhydrophobic titanium dioxide coating solution: mix 0.1g titanium dioxide powder with 10mL absolute ethanol, and then ultrasonicate at 100Hz for 30min to form a 0.01g / mL titanium dioxide suspension, then add 0.2mL octadecyltrimethoxy Silane, continue to ultrasonically mix under the condition of 100Hz, and then react at room temperature for 12h to obtain a superhydrophobic titanium dioxide coating solution; the volume ratio of the octadecyltrimethoxysilane to the titanium dioxide suspension is 0.02:1;

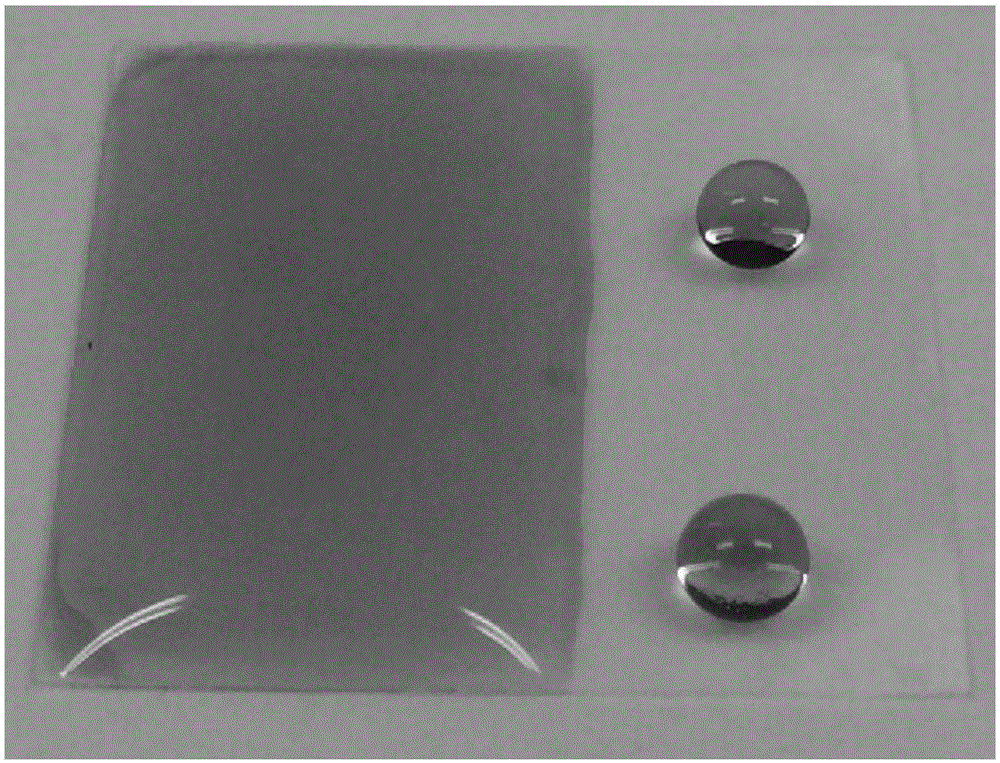

[0030] 2) Preparation of a substrate with a superhydrophobic layer: use a spin coater to spin-coat the superhydrophobic titanium dioxide coating solution onto the cleaned upper surface of the substrate, and then place it in an oven for 1 hour at 100°C to obtain a substrate with a superhydrophobic layer Th...

Embodiment 2

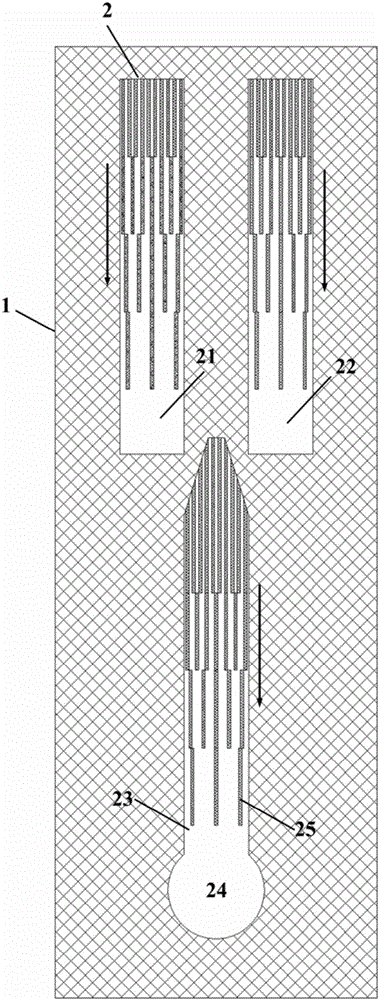

[0037]Example 2 The microreactor constructed according to the preparation method described in Example 1 is characterized in that: it includes a substrate 1 and a hydrophilic-hydrophobic layer 2 coated on the surface of the substrate, and the described hydrophilic-hydrophobic layer is provided with three hydrophilic Water channel, and the three channels are arranged in an "inverted character", of which the two parallel inlet channels in the upper part are 21 and 22, and the channel for transporting the reaction reagents after fusion is 23, and the reagents after the final reaction enter the destination 24; the three hydrophilic flow channels are divided into multiple regions, each region is designed with a number of equidistant super-hydrophobic strip patterns 25, and from the beginning to the end of the flow channel, the super-hydrophobic stripe patterns of adjacent regions The spacing of the hydrophobic strip pattern increases, that is, the proportion of the hydrophilic region...

Embodiment 3

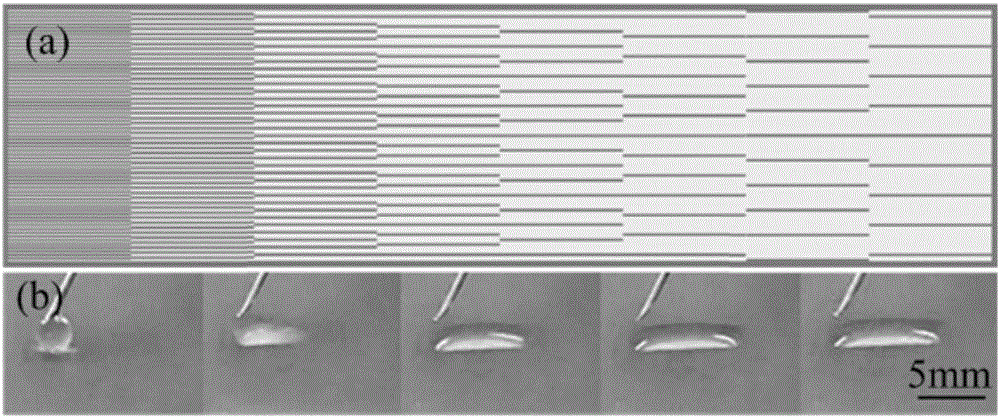

[0038] Embodiment 3 The movement of liquid droplets in a single channel:

[0039] designed as image 3 The flow channel shown in (a) has a width of 2 mm and a total length of 8 mm. Eight different regions are designed from left to right. The hydrophobic units in each region are 100 μm, and the distance between hydrophobic units gradually increases. , that is, the proportion of the hydrophilic region increases gradually, forming a wetting gradient in the flow channel. After exposure to light, a flow channel that can realize droplet self-driving is obtained. The optical picture of droplet self-driving in the flow channel is as follows: image 3 As shown in (b), a reasonable design of the wetting gradient in the channel can realize the customization of the flow rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com