An Adaptive Detection and Control Method of Welding Width in Narrow Gap Welding

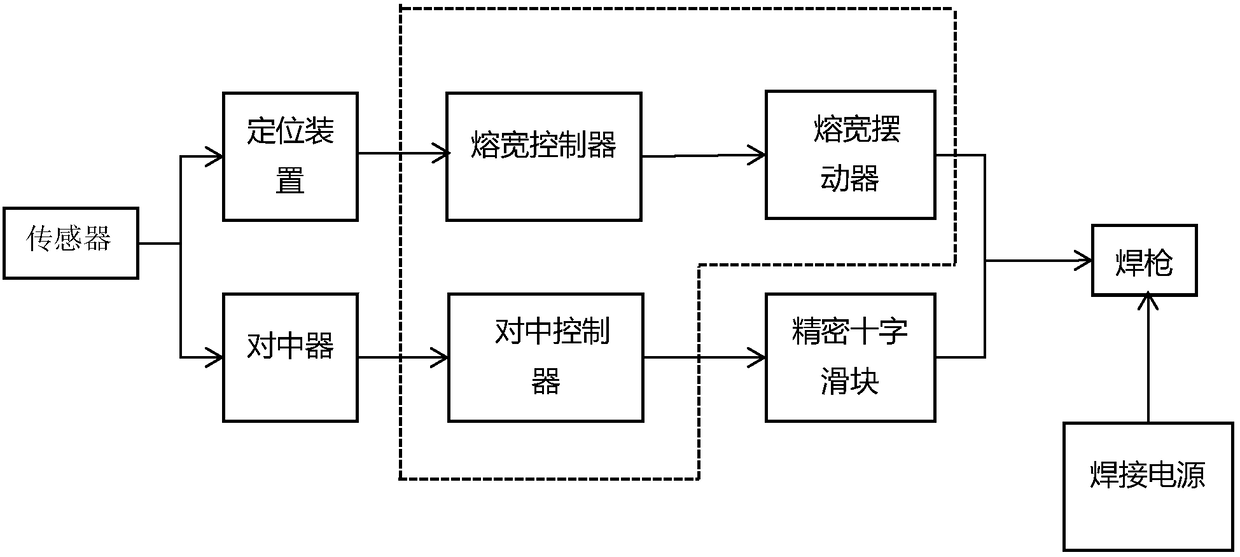

An adaptive detection and control method technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve problems such as welding defects, uneven melting width in narrow gaps, etc., achieve strong applicability, eliminate the impact of detection accuracy, The effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with accompanying drawings and embodiments, but the present invention is not limited.

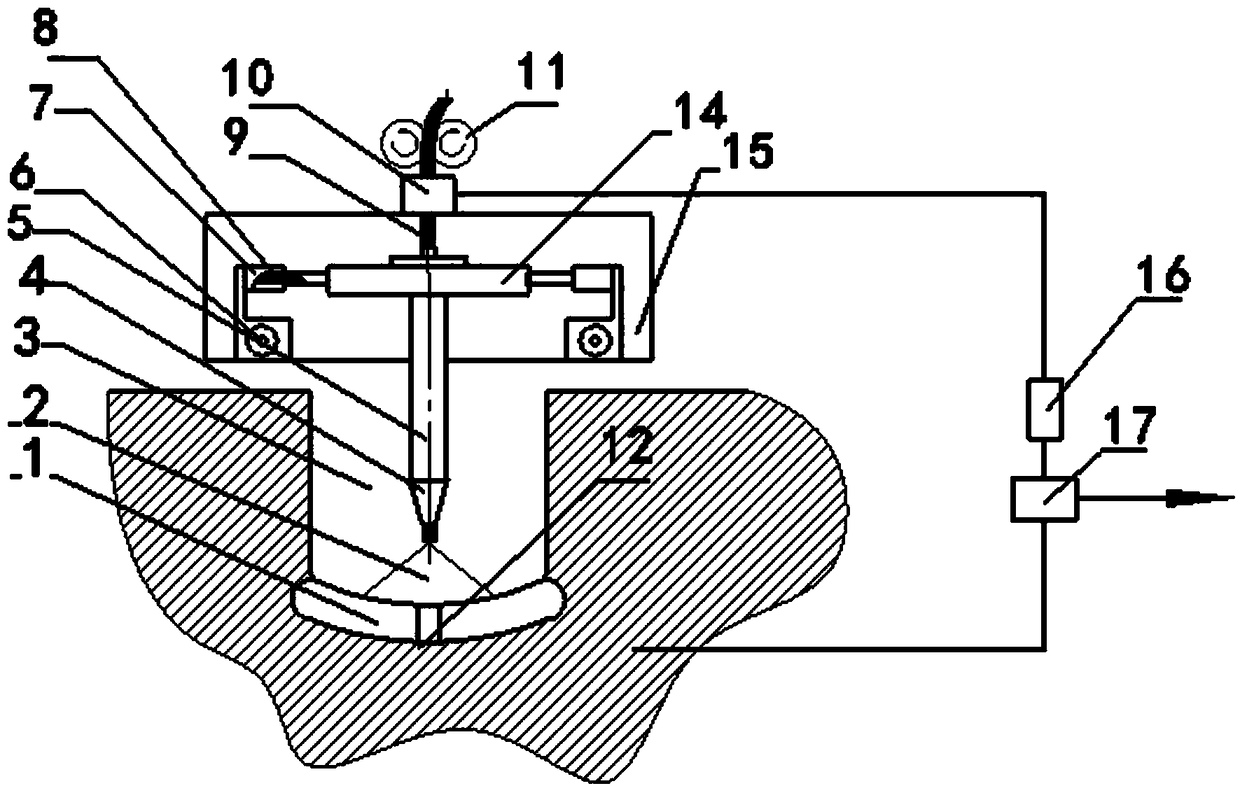

[0021] 1. If figure 2 As shown, the welding wire is sent out from the center hole of the conductive tip 4 after passing through the conductive rod, and the pulse welding power supply 16 supplies power to the welding arc 2 through the feeding and rotating device 10; during the welding process, the feeding and rotating device 10 drives the bending conductive rod 5 With the contact tip 4 and the welding width oscillator 15, the arc 2 is driven to vibrate in a circular arc shape with a certain radius in the narrow gap welding groove to form a welding pool 1 to realize narrow gap pulse welding of the oscillating arc. At the same time, it is detected by the Hall current sensor 17 Pulse arc current I.

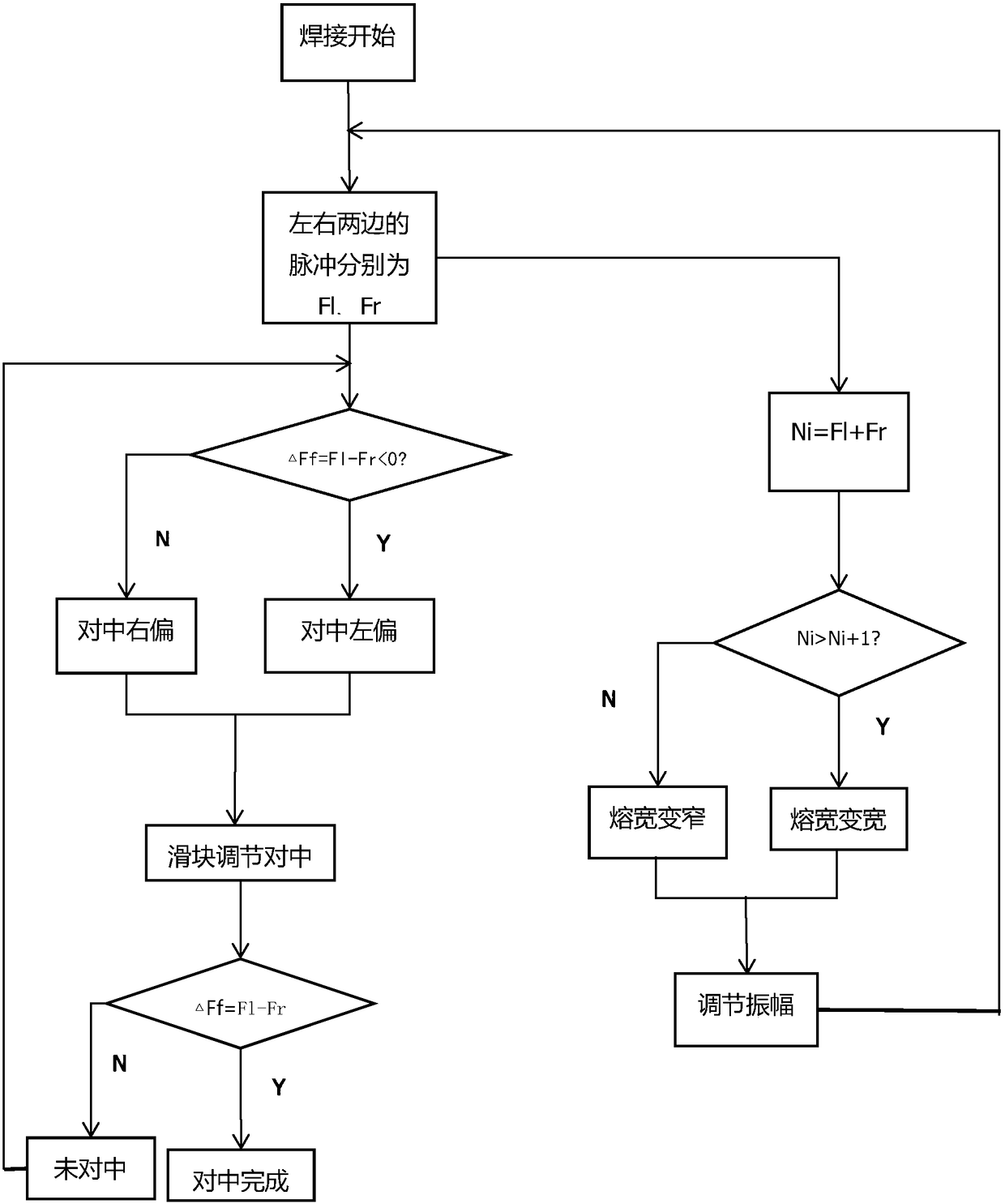

[0022] In the above swing arc welding process, when on the left side wall, a large current signal is detected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com