A double-acting manipulator

A manipulator and double-acting technology, applied in manipulators, program-controlled manipulators, metal processing, etc., can solve the problems of not being able to directly apply filter element replacement operations, manipulator single grabbing function, and long-term work, so as to improve operating efficiency and reduce Effect of small impact and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings. The embodiment is based on the specific implementation carried out on the premise of the technical solution of the present invention, and provides detailed implementation methods and processes. But the protection scope of the claims of the present application is not limited to the description of the following embodiments:

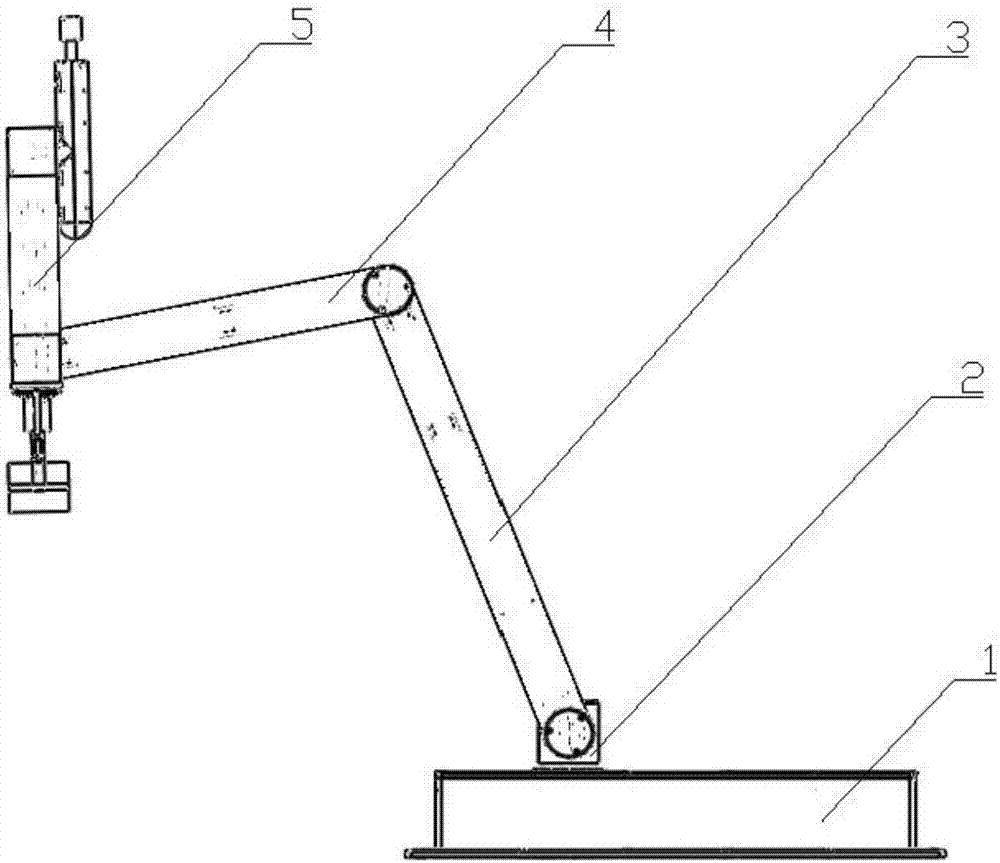

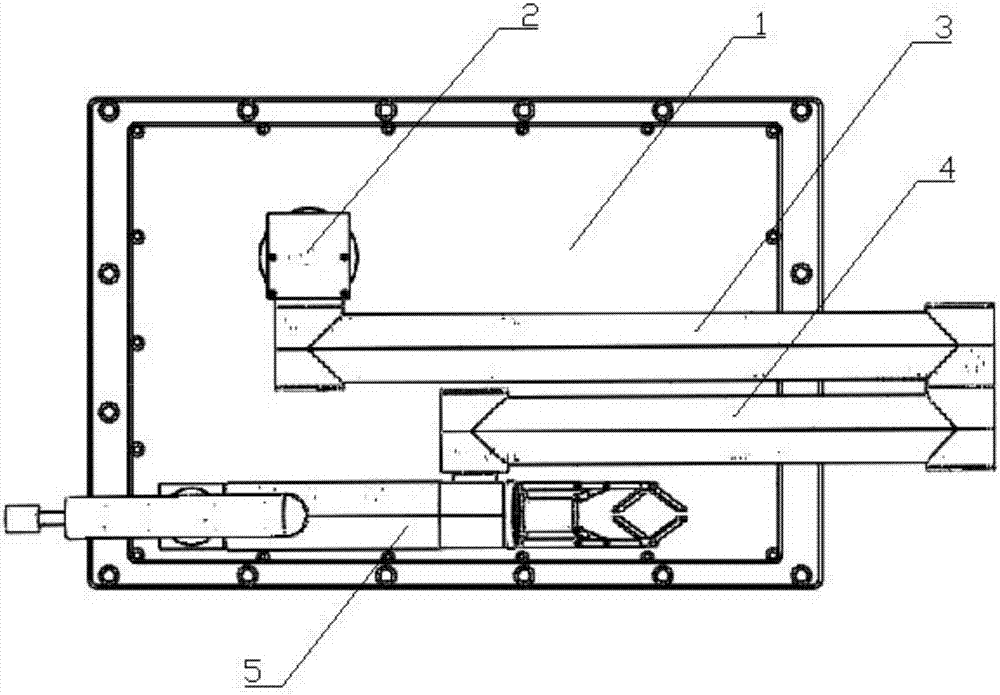

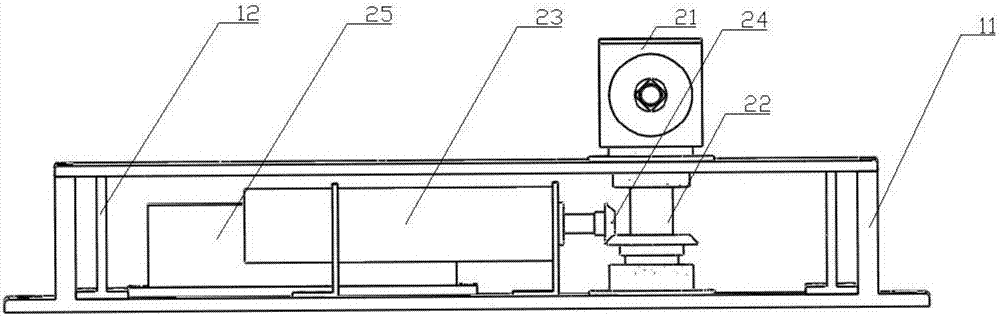

[0026] Double-acting manipulator of the present invention (abbreviation manipulator, see Figure 1-8 ) includes a base 1, a waist 2, a large arm 3, a small arm 4 and an end effector 5, wherein the base 1, the waist 2, the large arm 3, the small arm 4 and the end effector 5 are sequentially connected by a hollow joint shaft , and wiring inside the manipulator; the base 1 and the waist 2 are connected through the waist hollow joint shaft 22, the waist 2 and the upper arm 3 are connected through the shoulder hollow joint sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com